Solar panel production equipment and machinery

Nowadays the solar panels'' production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and

Get a quote

Solar Manufacturing Cost Analysis | Solar Market Research

Solar Manufacturing Cost Analysis NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and solar-coupled energy storage

Get a quote

Custom Solar Panel Production Line | One-Stop

Shuofeng is a professional solar panel production line and industrial laser processing system, provider. Have more than 10 years of experience in the

Get a quote

What is the Manufacturing Process of Solar Panels?

From the high-tech purification of silicon to the precise assembly of panels, the manufacturing of solar panels is a complex process designed to

Get a quote

Solar Panel Manufacturing : Process, Production

Understanding the manufacturing processes of solar panels is essential for renewable energy enthusiasts. This comprehensive article covers

Get a quote

FS: Solar agro-processing

The market for solar agro-processing machinery is greatly determined by the composition of crops in the local agricultural sector; for example, in Kenya, smallholder agro-processing is highest

Get a quote

Solar Panel Making Machines: A Guide to the Production

In this comprehensive guide, you will discover a fundamental overview of solar panel making machines and production processes essential for understanding solar panel

Get a quote

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get a quote

Solar Panel Manufacturing Challenges & Opportunities

Solar energy is booming, and solar panel manufacturing is at the heart of this revolution. As demand for clean energy soars worldwide, manufacturers face increasing

Get a quote

California may help solar bloom where water runs dry

8 hours ago· Photo by Larry Valenzuela, CalMatters/CatchLight Local Solar panels inside a solar farm and a fallow field on the Woolf Farming & Processing property outside of Huron on Aug.

Get a quote

Solar Manufacturing | Advanced Manufacturing Research | NREL

Solar Manufacturing NREL is advancing next-generation manufacturing processes and technologies for clean electric power generation by improving the composition, thermal

Get a quote

Solar Panel Manufacturing: A Comprehensive Guide

Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to capture energy from the sun and convert it into usable

Get a quote

E-scrap sector continues solar processing push

Electronics processors are increasingly adding solar panel recycling capacity, in some cases processing the panels similarly to declining

Get a quote

ADVANCING SOLAR PANEL EFFICIENCY – INNOVATIONS,

A typical commercial installation of solar PV panels. Image by Freepik The extreme weather-related events of recent years have amply demonstrated the degradation of Planet

Get a quote

Solar panel glass manufacturer

Solaris, the future of solar energy Solaris Industry is a subsidiary of CEVITAL group, specialized in ultra-clear glass production, solar glass processing, and photovoltaic modules assembling.

Get a quote

How to Manufacture Solar Panel – A Complete Guide

In this guide, we will take you through the step-by-step process of manufacturing solar panels, discussing the materials used, production

Get a quote

How to Manufacture Solar Panel – A Complete Guide

In this guide, we will take you through the step-by-step process of manufacturing solar panels, discussing the materials used, production methods, and cost factors involved.

Get a quote

ESR | Solar Panel Recycling

A solar panel converts the sun''s radiant energy into electricity using photovoltaic cells commonly known as solar cells. A solar panel includes solar cells, photovoltaic modules, and

Get a quote

Solar Panel Manufacturing

Epcon Industrial Systems delivers cutting-edge technology, customized solutions, and industry expertise to support the evolving needs of solar panel manufacturers. Contact us today to

Get a quote

Solar Panel Manufacturing : Process, Production Stages

Understanding the manufacturing processes of solar panels is essential for renewable energy enthusiasts. This comprehensive article covers the main aspects of solar

Get a quote

Solar Panel Manufacturing: A Comprehensive Guide for Beginners

Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to capture energy from the sun and convert it into usable electricity. This involves

Get a quote

Solar Panel Manufacturing Process Explained

Discover the solar panel manufacturing process at Anmak Solar. Learn how to manufacture solar panels efficiently and sustainably. Start your

Get a quote

Solar panel manufacturing process: from cell to module

During lay-up, solar cells are stringed and placed between sheets of EVA. The next step in the solar panel manufacturing process is lamination.

Get a quote

What is the Manufacturing Process of Solar Panels?

From the high-tech purification of silicon to the precise assembly of panels, the manufacturing of solar panels is a complex process designed to maximize efficiency and

Get a quote

How the recycling industry is preparing to tackle solar

In some ways, solar panels present some of the same recycling challenges as old TVs. They carry a high cost to recycle properly, have limited

Get a quote

What Happens After 25 Years? Solar Panel Lifespan & Recycling

Learn how long solar panels last, how performance changes after 25 years, and your options for recycling or upgrading when the time comes.

Get a quote

Solar Panel Manufacturing: A Comprehensive Guide to the

Discover the fascinating world of solar panel manufacturing, where cutting-edge technology meets sustainable energy production. This comprehensive guide explores the

Get a quote

6 FAQs about [Solar panel processing industry]

What is solar panel manufacturing?

Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to capture energy from the sun and convert it into usable electricity. This involves assembling components including solar cells, a frame, and a glass covering. The process requires advanced technology and expertise in semiconductor and PV cell production.

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

What is solar energy production?

At the heart of solar energy production lies solar photovoltaic (PV) manufacturing. Photovoltaic refers to the process of converting sunlight directly into electricity, harnessing photons (units of light) to generate voltage. PV modules are the primary components in a solar panel, converting light directly to electricity.

How do solar panel manufacturers create essential energy solutions?

But have you ever wondered how solar panel manufacturers create these essential energy solutions? The solar panel manufacture process involves multiple steps, from raw material selection to the final testing phase, ensuring maximum solar power efficiency and durability.

How are solar panels made?

The key components in solar PV manufacturing include silicon wafers, solar cells, PV modules, and solar panels. Silicon is the primary material used, which is processed into wafers, then assembled into solar cells and connected to form solar modules.

Do solar panels have an environmental impact?

Solar panel manufacturing has an environmental impact, primarily due to the energy-intensive process of producing silicon. However, the overall environmental impact of solar panels is significantly lower than that of fossil fuel-based energy sources.

Guess what you want to know

-

Norway solar panel wholesale processing photovoltaic roof BESS

Norway solar panel wholesale processing photovoltaic roof BESS

-

Is solar panel a cyclical industry

Is solar panel a cyclical industry

-

Solar panel back-end processing

Solar panel back-end processing

-

Layout of solar panel industry

Layout of solar panel industry

-

Liechtenstein Solar Panel Industry Cluster

Liechtenstein Solar Panel Industry Cluster

-

Solar panel industry development

Solar panel industry development

-

How many watts does a 36 volt solar panel hold

How many watts does a 36 volt solar panel hold

-

Solar panel 4 watts

Solar panel 4 watts

-

Solar panel wattage selection

Solar panel wattage selection

-

Photovoltaic solar panel voltage

Photovoltaic solar panel voltage

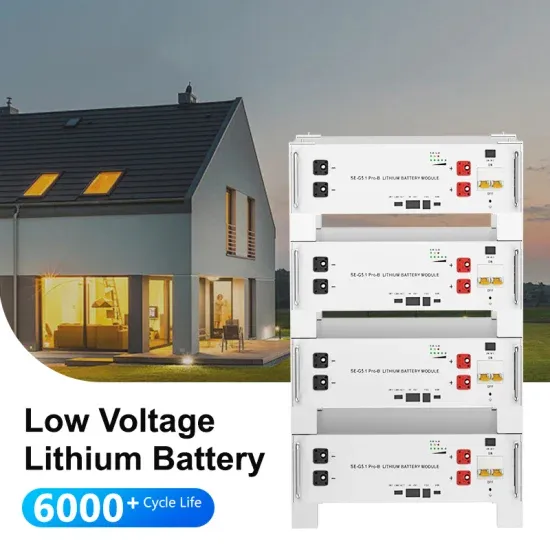

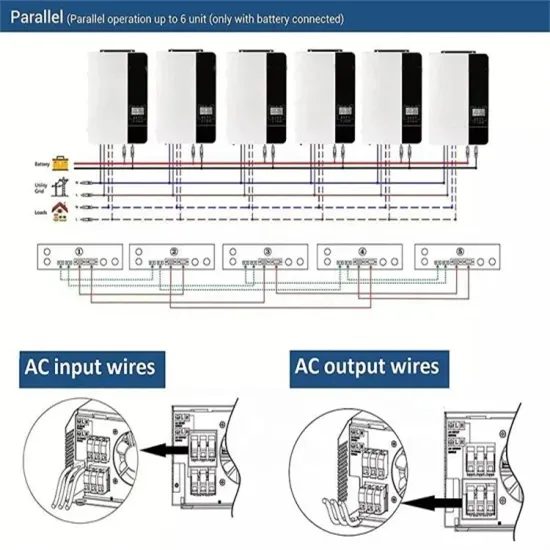

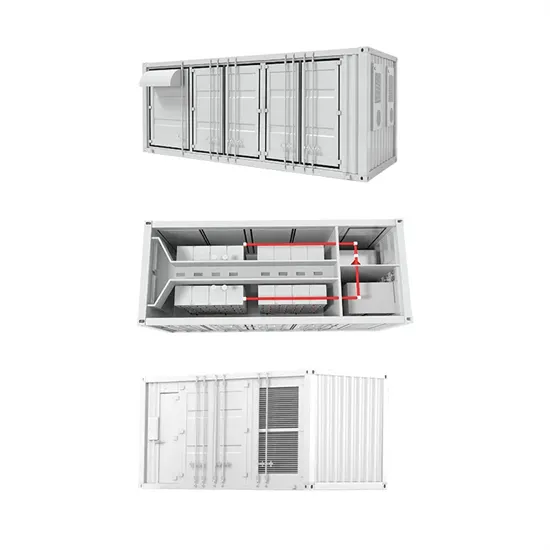

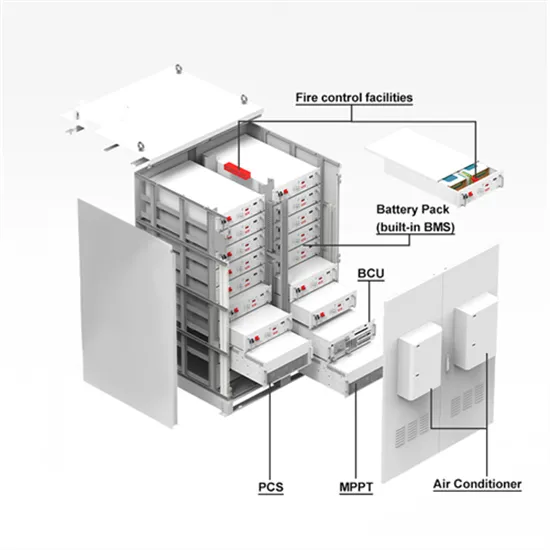

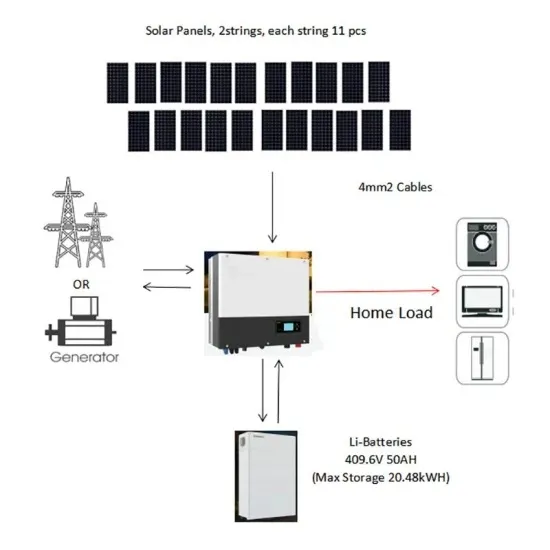

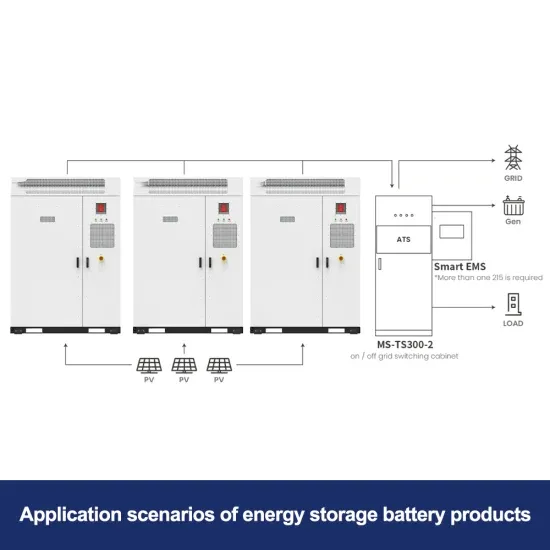

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.