Recycling of end-of-life solar panels: Focusing on the pyrolysis

These findings are of great significance for improving the recycling of end-of-life solar panels, particularly with regard to their pyrolysis conversion. This is especially relevant

Get a quote

A comprehensive review on the recycling technology of silicon

Recycling PV panels through e-waste management is crucial step in minimizing the environmental impact of end-of-life PV systems such as the release of heavy metals into the

Get a quote

Manufacturing Process of Photovoltaic Panels | Ecoprogetti

Today, the industry has cutting-edge machinery capable of working in synergy to create next-generation photovoltaic modules, from P-type PERC, N-type TOPCon, N-type HJT cells to

Get a quote

The Lifecycle of Solar Panels: From Raw Materials to

Discover the hidden journey behind solar energy as we uncover the intricate lifecycle of solar panels. From the extraction of raw materials to

Get a quote

Solar Panel Manufacturing: A Comprehensive Guide to the Process

Discover the fascinating world of solar panel manufacturing, where cutting-edge technology meets sustainable energy production. This comprehensive guide explores the

Get a quote

The Lifecycle of Solar Panels: From Raw Materials to Recycling

Discover the hidden journey behind solar energy as we uncover the intricate lifecycle of solar panels. From the extraction of raw materials to their end-of-life management,

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar

Get a quote

How are Solar Panels Made? | The Scientific Steps | Ossila

To make solar panels, you need high quality silicon. Producing silicon wafers requires 5 stages: heating, purification, doping, shaping and polishing.

Get a quote

Solar Panel Manufacturing: A Comprehensive Guide to the

Discover the fascinating world of solar panel manufacturing, where cutting-edge technology meets sustainable energy production. This comprehensive guide explores the

Get a quote

Removing and Reinstalling Solar Panels: Process and

Rarely, you may need to remove and reinstall your solar panels. We''ll guide you through the process, expected cost, and usual questions.

Get a quote

Understanding Solar Panel Recycling: A Complete Guide

As the world leans into renewable resources, the surge in solar panel installations is hard to miss. Yet, the lifecycle of a solar panel, typically ranging from 25 to 30 years, raises a

Get a quote

Solar Panel Manufacturing''s Environmental Impact:

Recent technological breakthroughs in silicon processing and recycling methods have dramatically improved the sustainability profile of solar

Get a quote

What are the front and back processes of solar panels?

Parallel to the processes on the front end, the back mechanisms of solar panels are equally paramount in ensuring comprehensive electricity generation. While the front

Get a quote

Solar Panel Installation Process: A Homeowner''s Guide

However, a proper solar panel installation process can make solar viable even for less-than-perfect homes. A solar installer can help you

Get a quote

Solar Photovoltaics Value Chain and End-of-Life

Many challenges emerge in the life cycle of solar photovoltaic (PV) panels throughout the processes of their deployment and use in residential,

Get a quote

Solar panel manufacturing process: from cell to module

Solar panel manufacturing process After having produced the solar cells and placed the electrical contacts between the cells, they are then wired and

Get a quote

(PDF) Analyzing the lifecycle of solar panels including raw

Analyzing the lifecycle of solar panels including raw material sourcing, manufacturing, and end-of-life disposal October 2024 World Journal of Advanced Engineering

Get a quote

Transferring Ownership of Your Solar System | Tesla

The solar system works in tandem with the local utility company through a process called Net Energy Metering (NEM). During the day, you will use all

Get a quote

Recycling of end of life photovoltaic panels: A chemical prospective

The most targeted metal in the recycling process of this panel type is silver, which is present on the front and back side of the solar cell as electrode (Nieland et al., 2012, Tao and

Get a quote

Analyzing the lifecycle of solar panels manufacturing, and

Despite the substantial reduction in greenhouse gas emissions attributable to solar panels throughout their operational lifespan, there is a pressing need for enhancements in material

Get a quote

How Are Solar Panels Made: Journey from Sand to Solar Panel

The quality of a solar panel depends on the standard of the EVA sheet, glass, back sheet, solar cells, and the manufacturing equipment used to assemble the module. Though

Get a quote

Manufacturing Process of Photovoltaic Panels

Today, the industry has cutting-edge machinery capable of working in synergy to create next-generation photovoltaic modules, from P-type PERC, N-type

Get a quote

4JET''s high volume system lowers costs for back end processing

In relation to large-scale CIGS thin-film fabs with a nameplate capacity of 300MW, up to now the 3 process steps would require at least 5 process lines with a total of up to 15 machines to carry

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal

Get a quote

太陽能板回收市場(按製程類型、電池板類型和最終用

5.8. Shift toward modular solar panel designs simplifies end-of-life dismantling and material separation processes 6. Market Insights 6.1. Porter''s Five Forces Analysis 6.2.

Get a quote

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get a quote

Solar Panel Manufacturing''s Environmental Impact: The Truth

Recent technological breakthroughs in silicon processing and recycling methods have dramatically improved the sustainability profile of solar panel production, reducing the

Get a quote

6 FAQs about [Solar panel back-end processing]

How do solar panels work?

Understanding the manufacturing process of solar panels can help you understand how this technology works. Solar energy can be captured using two primary methods: Photovoltaic (PV) System: This technology converts sunlight directly into electricity using solar panels made of semiconductor materials like silicon.

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

How are solar panels reducing the environmental footprint?

Advanced manufacturing processes are significantly reducing the environmental footprint of solar panel production while improving efficiency and reducing costs. Key innovations include the development of lead-free solar cells, which eliminate toxic materials from the manufacturing process.

What are the environmental benefits of solar panel recycling?

The environmental benefits of solar panel recycling extend beyond material recovery. By reclaiming raw materials, the industry reduces the need for new resource extraction, minimizes landfill usage, and decreases the carbon footprint associated with manufacturing new panels.

How are solar panels made?

The key components in solar PV manufacturing include silicon wafers, solar cells, PV modules, and solar panels. Silicon is the primary material used, which is processed into wafers, then assembled into solar cells and connected to form solar modules.

Can solar panels be recycled?

Modern recycling processes can recover up to 95% of semiconductor materials and 90% of glass from decommissioned panels. These materials are then repurposed for manufacturing new panels or used in other industries, significantly reducing the environmental impact of solar technology.

Guess what you want to know

-

Norway solar panel wholesale processing photovoltaic roof BESS

Norway solar panel wholesale processing photovoltaic roof BESS

-

Solar panel processing industry

Solar panel processing industry

-

Vietnam photovoltaic panel single solar panel

Vietnam photovoltaic panel single solar panel

-

Myanmar solar panel assembly

Myanmar solar panel assembly

-

Smallest 50v solar photovoltaic panel

Smallest 50v solar photovoltaic panel

-

Bosnia and Herzegovina Solar Panel Photovoltaic Panel Company

Bosnia and Herzegovina Solar Panel Photovoltaic Panel Company

-

Top 10 solar panel brands

Top 10 solar panel brands

-

How many watts does a two-in-one solar panel require

How many watts does a two-in-one solar panel require

-

Which type of photovoltaic solar panel generates more electricity

Which type of photovoltaic solar panel generates more electricity

-

Zambian photovoltaic photovoltaic solar panel manufacturer

Zambian photovoltaic photovoltaic solar panel manufacturer

Industrial & Commercial Energy Storage Market Growth

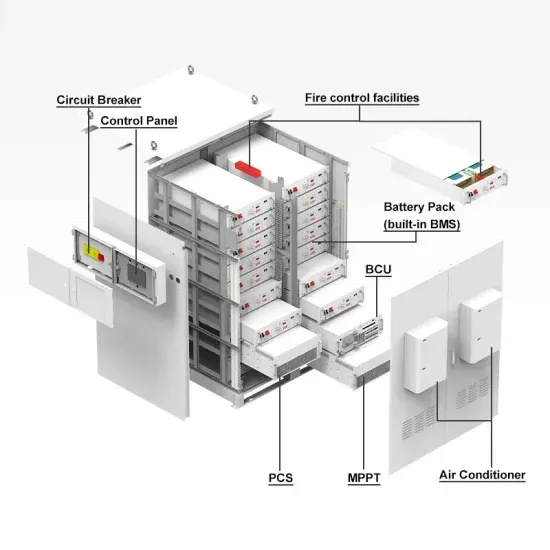

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.