Inverter Amp Draw Calculator: Let''s Simplify It

Short on Time? Here''s The Article Summary The article discusses the importance of monitoring the amp draw of an inverter in a solar power system to manage

Get a quote

How Many Batteries for 4000 Watt Inverter – MWXNE

Conclusion If you want to choose the right number of batteries for a 4000-watt inverter, you need to consider multiple factors such as input

Get a quote

How many batteries are needed to run a 3000 watt

To run a 3000 watt inverter, you would need a battery bank with a capacity of at least 1000 amp-hours (AH) for a 4-hour runtime. This can be

Get a quote

How many batteries do I need for a 3.5 kVA inverter

The 3.5kva/48V inverter provides a UPS mode to ensure that even the most sensitive equipment runs uninterrupted during system switchover to the battery supply. How long does it take to

Get a quote

How Many Lithium Batteries Do You Need for a 5000W Inverter?

Battery Configurations for a 5000W Inverter Here are some common configurations based on the system voltage and battery capacity: 48V System with 100Ah Batteries: You

Get a quote

What Inverter Size is Best for a 100Ah Battery?

Understanding the Basics What is an Inverter? An inverter converts DC (Direct Current) power from your battery into AC (Alternating Current) power, which is used by most household

Get a quote

Calculate Battery Size for Inverter Calculator

Estimate the battery capacity required for your inverter based on power load, runtime, and efficiency. Using the Calculate Battery Size for Inverter Calculator can

Get a quote

How to Calculate Battery Size for Inverters of Any Size

In order to size a battery bank, we take the hours needed to continuously run your inverter and multiply them by the number of watts the inverter is designed for. This equals the total watt

Get a quote

What Will An Inverter Run & For How Long? (With

So because of the inverter''s efficiency rate, your 1000W inverter will have to pull 1150 watts from the battery if you''re running it at its full capacity.

Get a quote

How Many Batteries Do I Need? (How to Calculate

For systems beyond 5kW, you will need 4 batteries for your inverter to function properly, as they are 48V. If you still need more power from batteries, you can

Get a quote

What Size Inverter Do I Need?

Inverter Size Calculator Learning how to calculate inverter size for your needs can be a tricky task, especially if you''re unfamiliar with how an inverter works or

Get a quote

How Many Batteries Are Needed For A 5000 Watt

For the power supply requirement of a 5000-watt inverter, you may ask: How many batteries do we need to meet this requirement? In this article,

Get a quote

How Many Batteries Do I Need for a 48V Inverter?

To determine how many batteries you need for a 48V inverter, you must consider the inverter''s power rating, the capacity of the batteries, and your energy usage requirements.

Get a quote

What Will An Inverter Run & For How Long? (With Calculator)

So because of the inverter''s efficiency rate, your 1000W inverter will have to pull 1150 watts from the battery if you''re running it at its full capacity. This is not recommended

Get a quote

48V Inverter: The Ultimate Guide to Efficient and Scalable Power

Unlock efficient power solutions with a 48V inverter—perfect for solar, off-grid, and backup systems. Learn how to choose the best one for your needs now!

Get a quote

Calculating Battery Requirements for an 8000W Solar Inverter

Battery secrets for your 8000W solar inverter unveiled! Embrace clean energy and break free from the grid. Let the sun lead the way!

Get a quote

How Many Batteries for 4000 Watt Inverter – MWXNE POWER

Conclusion If you want to choose the right number of batteries for a 4000-watt inverter, you need to consider multiple factors such as input voltage, battery capacity, system

Get a quote

Inverter Amp Draw Calculator

To calculate the amp draw for inverters at different voltages, you can use this formula. Maximum Amp Draw (in Amps) = ( Watts ÷ Inverter''s Efficiency (%)) ÷ Lowest Battery

Get a quote

How Many 48Volts Batteries Do I Need for a 5000W, 5KW or 5kVA Inverter!

In Zimbabwe, where power outages are frequent, investing in a solar power system with an inverter and batteries is essential. A common question is: " How many 48V batteries do I need

Get a quote

Battery Runtime Calculator | How Long Can A Battery

The Battery Runtime Calculator is an indispensable tool for anyone using batteries for power supply, be it in RVs, boats, off-grid systems,

Get a quote

How Many Batteries For A 5KVA/48V Inverter? Answered

With more batteries, the voltage rises, increasing the power output (measured in watts). The inverter receives 104ah per hour when powered by four 210ah 48V batteries. The

Get a quote

Calculate Battery Size For Any Size Inverter (Using Our Calculator)

To recharge your battery from time to time you would need the right size solar panel to do the job! Read the below article to find out the suitable solar panel size for your battery bank

Get a quote

How Many Batteries Do I Need for a 5000W Inverter

With four 210ah 48V batteries, the inverter receives 104ah hourly. With a full discharge the inverter can run at maximum load for two hours or 10kwh (10,000W). Bottom line: no matter

Get a quote

How Do You Calculate the Appropriate Inverter Size for a 48V

To calculate the appropriate inverter size for a 48V battery system, you need to determine the total wattage of the devices you plan to power. The formula is: Inverter Size

Get a quote

How Do You Calculate the Appropriate Inverter Size for a 48V Battery

To calculate the appropriate inverter size for a 48V battery system, you need to determine the total wattage of the devices you plan to power. The formula is: Inverter Size

Get a quote

How many batteries do I need for a 1500 watt power

One of the most common questions when using a 1500 watt inverter is "How many batteries do I need to support its operation?" This

Get a quote

6 FAQs about [How much battery does a 48v inverter require ]

How many 24V batteries do you need for a 48V inverter?

Similarly, you need to connect two 24V batteries in parallel to provide a 48V output voltage. If your 24V battery voltage is 100AH, then you need 3 groups, that is, six 24V 100AH batteries to power the inverter. 48V Battery System

How many watts can a 48V inverter run?

With four 210ah 48V batteries, the inverter receives 104ah hourly. With a full discharge the inverter can run at maximum load for two hours or 10kwh (10,000W). Bottom line: no matter what the battery bank voltage, it must provide 5000W for every hour you want the inverter to operate.

What is the recommended battery size for an inverter?

Interpreting Results: Once you input the required data, the calculator will generate the recommended battery size in ampere-hours (Ah). For instance, if your power consumption is 500 watts, the usage time is 4 hours, and the inverter efficiency is 90%, the calculator might suggest a battery size of approximately 222 Ah.

How many batteries do I need for a 4000-watt inverter?

If you are using a 48V 100Ah battery, you only need to connect 3 batteries in parallel to meet the 3-hour operation of the 4000-watt inverter. When choosing a battery, common battery types include lead-acid batteries and lithium-ion batteries. Each battery has its advantages and disadvantages:

Can a 5000W inverter use a 48v battery?

Most 5000W inverters have a 24V or 48V input. You can buy 48V batteries or any battery volt as long as the total is 48. Do not let lead acid battery discharges drop below 50%. When calculating battery sizes for inverters, assume that you will use only 50% of the battery capacity.

How many amps in a 48 volt inverter?

Now, maximum amp draw (in amps) = (1500 Watts ÷ Inverter’s Efficiency (%)) ÷ Lowest Battery Voltage (in Volts) = (1500 watts / 95% ) / 20 V = 78.9 amps. B. 100% Efficiency In this case, we will consider a 48 V battery bank, and the lowest battery voltage before cut-off is 40 volts. The maximum current is, = (1500 watts / 100% ) / 40 = 37.5 amps

Guess what you want to know

-

How big of an inverter can a 48v lead-acid battery be connected to

How big of an inverter can a 48v lead-acid battery be connected to

-

How big of an inverter can a 12A 48V battery power

How big of an inverter can a 12A 48V battery power

-

How big a battery does a 2200W inverter require

How big a battery does a 2200W inverter require

-

Can the inverter be connected to a 48V lithium battery

Can the inverter be connected to a 48V lithium battery

-

Can a 38v lithium battery be used with a 48v inverter

Can a 38v lithium battery be used with a 48v inverter

-

How many watts does an 8-string lithium battery inverter in the UAE have

How many watts does an 8-string lithium battery inverter in the UAE have

-

How big a battery is needed for a 24v 3000 inverter

How big a battery is needed for a 24v 3000 inverter

-

48v battery with inverter can be used for several hours

48v battery with inverter can be used for several hours

-

How many batteries does an 8kva inverter require

How many batteries does an 8kva inverter require

-

How many watts does a 48v inverter use

How many watts does a 48v inverter use

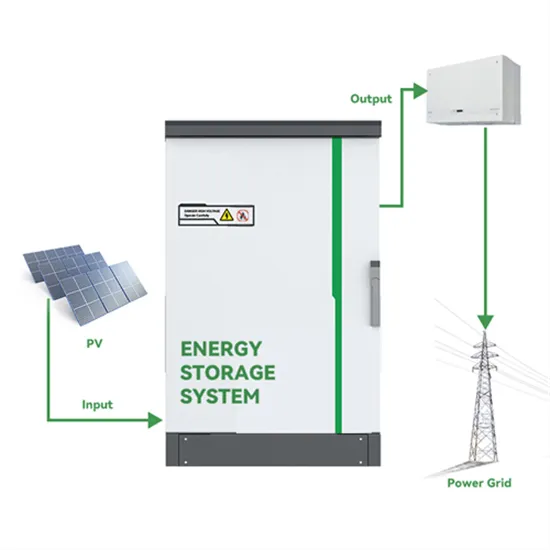

Industrial & Commercial Energy Storage Market Growth

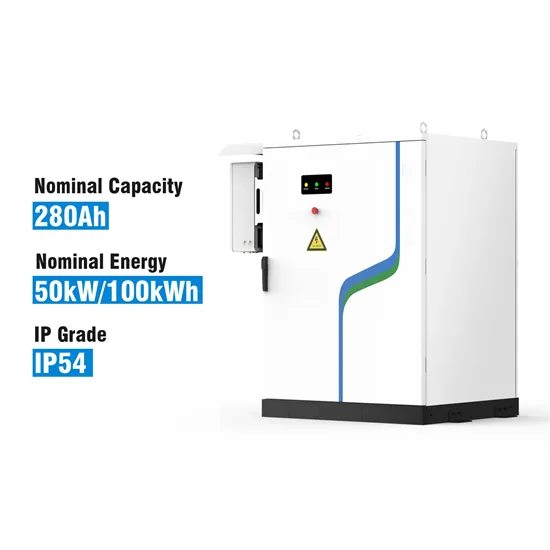

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

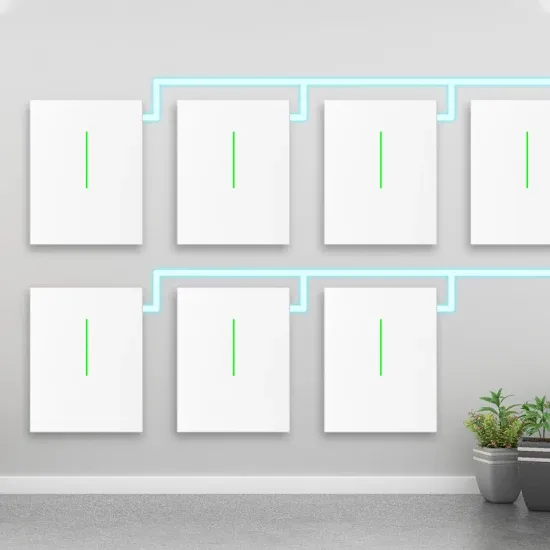

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.