Sturcture of Battery: From Cell to Module and Pack | How are Batteries

The Structure of a Battery To review a battery''s structure from a macro-view as a whole pack until the smallest units, which are referred to as battery cells, batteries are by no

Get a quote

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

This technical guide examines the internal structure of lithium ion batteries and provides detailed procedures for constructing battery packs from individual components.

Get a quote

EV battery : serie vs. parallel cells and modules

Challenges in setups with parallel cells / modules and packs in EV conversions. Do''s and don''ts for more battery capacity (kWh) explained. Don''t

Get a quote

Series and Parallel, which is the first when assembling

Series and Parallel, which is the first when assembling lithium battery packs? In the design of the battery modules, whether to connect them

Get a quote

White Paper

For an in depth analysis, please see section 6.1.1.1, "Cells in parallel versus batteries in parallel" of the Battery Management Systems for Large Lithium-Ion Battery Packs book.

Get a quote

Power Battery Basics: Cells, Modules & Packs Explained

Explore the key elements of a power battery—cells, modules, and packs. Learn how they form the core of EV and ESS technology, and the role

Get a quote

Parallel Battery Packs

We''ve been looking at truck battery packs and a common thread is the parallel battery packs approach. As there is no need for a propshaft the packs are being arranged

Get a quote

EV Lithium Battery PACK Design Process from Manufacturers

EV Lithium Battery PACK Design Process: A Comprehensive Guide The design of Electric Vehicle (EV) lithium battery packs ⇱ is a complex and critical process that directly

Get a quote

How to Assemble a Lithium-Ion Battery Pack with a BMS Module:

Cells in Parallel (P): Increases capacity (mAh). Connecting cells in parallel keeps the voltage the same but increases the total capacity. Example: A 4S2P configuration means 4

Get a quote

Complete Guide to Lithium Battery Pack Design and Assembly

What is a Lithium Battery Pack? A lithium battery pack is an integrated battery system. It is built by connecting many individual cells in series and parallel. It includes a

Get a quote

Handbook On Lithium Battery Pack Design

The environment in which the battery pack is used and the electrical connection of the individual cells (series or parallel) are two key considerations when designing a battery pack and working

Get a quote

Battery Remanufacturing | UL Solutions

UL Solutions Provides Innovative Solutions For A Safer, More Secure And Sustainable World. Achieve Battery Compliance At Every Stage With UL Solutions Regulatory Support.

Get a quote

Helpful Guide to Lithium Batteries in Parallel and Series

Lithium battery series and parallel: There are both parallel and series combinations in the middle of the lithium battery pack, which increases

Get a quote

Lithium batteries for beginners. Step by step: balancing,

Lithium batteries for beginners. Step by step: balancing, assembling, capacity test. LiFePo4 DIY. SolarEngineering 24.9K subscribers Subscribe

Get a quote

How Are Lithium Battery Packs Assembled?

The assembly process of lithium battery packs is crucial for ensuring their optimal performance, safety, and longevity. This article explores the key steps involved in lithium battery pack

Get a quote

[Step Guide ] How to Solder Multiple Lithium Batteries?

Learn step-by-step how to solder lithium batteries in series or parallel safely and effectively with this detailed, hands-on guide.

Get a quote

Series and Parallel, which is the first when assembling lithium battery

In the industry, the current situation is that large-scale energy storage system often uses the series-first then parallel method, but in power applications like electric vehicle

Get a quote

BU-302: Series and Parallel Battery Configurations

BU-302: Configuraciones de Baterías en Serie y Paralelo (Español) Batteries achieve the desired operating voltage by connecting several cells in series;

Get a quote

Guide LiFePO4 Battery Pack Assembly

In this Instructable, I will show you, how to make a LiFePO4 Battery Pack for applications like Off-Grid Solar System, Solar Generator, Electric Vehicle,

Get a quote

How to Build a Lithium Battery Pack: From Cell Selection to

This article will focus on three core steps: cell selection, consistent placement and mounting, and series-parallel assembly.

Get a quote

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Designing a lithium-ion battery pack is a complex and multifaceted process that requires a deep understanding of the components, configurations, and safety considerations

Get a quote

Helpful Guide to Lithium Batteries in Parallel and Series

Lithium battery series and parallel: There are both parallel and series combinations in the middle of the lithium battery pack, which increases the voltage and capacity. Lithium

Get a quote

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

Get a quote

Design approaches for Li-ion battery packs: A review

The paper aims to investigate what has been achieved in the last twenty years to understand current and future trends when designing battery packs. The goal is to analyze the

Get a quote

How To Make A Lithium Battery Pack With 18650

In this video I show you how to make your own custom lithium battery pack using the common 18650 lithium cell. I talk about how to connect the cells in series

Get a quote

Guess what you want to know

-

Connect two lithium battery packs in parallel

Connect two lithium battery packs in parallel

-

Lithium battery packs in series and parallel

Lithium battery packs in series and parallel

-

Lithium-ion batteries and lithium battery packs

Lithium-ion batteries and lithium battery packs

-

Is it reliable to assemble lithium battery packs

Is it reliable to assemble lithium battery packs

-

Two identical 24V lithium battery packs in Croatia

Two identical 24V lithium battery packs in Croatia

-

Lithium iron phosphate 220v outdoor battery cabinet assembly

Lithium iron phosphate 220v outdoor battery cabinet assembly

-

4 parallel 10 series lithium battery pack

4 parallel 10 series lithium battery pack

-

Lithium battery packs can be exported

Lithium battery packs can be exported

-

UK lithium battery packs by 2025

UK lithium battery packs by 2025

-

North Macedonia lithium battery energy storage cabinet assembly plant

North Macedonia lithium battery energy storage cabinet assembly plant

Industrial & Commercial Energy Storage Market Growth

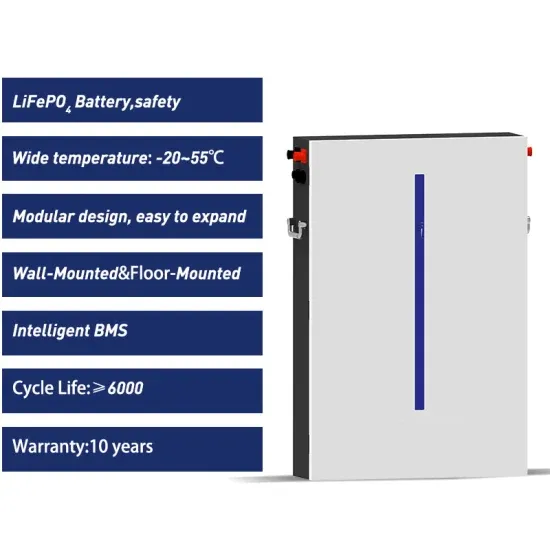

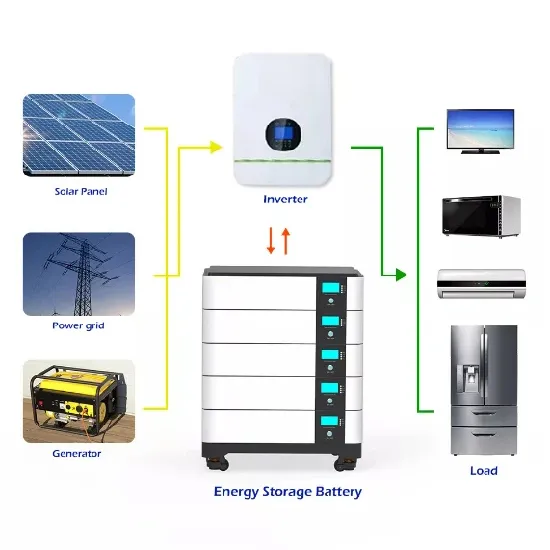

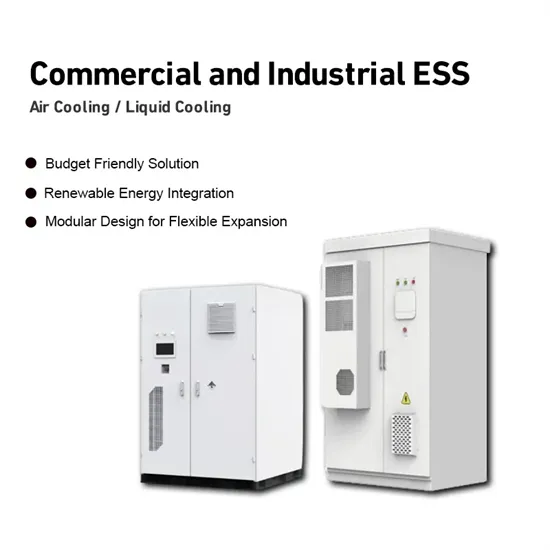

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.