How to Build Your Own Lithium Battery Pack: A Step-by-Step Guide

In today''s increasingly mobile world, having a reliable power source is essential. From powering gadgets to supporting renewable energy systems, building your own lithium

Get a quote

How to Build a Lithium Ion Battery Pack? A Step by Step Guide

Proper assembly will not only produce a battery that can function properly, but also help keep us safe while using the lithium-ion battery pack. Below is a list of materials and tools

Get a quote

Reliable

Calling something reliable means you can count on it to come through when you need it; it''s dependable. If you''re headed out for an around-the-world sailing trip, hopefully your lifejacket

Get a quote

Using Li-ion Battery Packs for Long Range FPV Drone

Discover the advantages of 18650/21700 Li-ion battery packs for long-range FPV drone flying, including extended flight times and how to build your own.

Get a quote

RELIABLE | definition in the Cambridge English Dictionary

RELIABLE meaning: 1. Someone or something that is reliable can be trusted or believed because he, she, or it works or. Learn more.

Get a quote

RELIABLE definition and meaning | Collins English Dictionary

reliable in American English (rɪˈlaiəbəl) adjective that may be relied on; dependable in achievement, accuracy, honesty, etc

Get a quote

How to assemble a 48V lithium battery pack by yourself?

A successfully assembled lithium battery pack can also be called a lithium battery pack, but a real lithium battery pack needs more materials in

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get a quote

How to assemble a lithium battery pack?

Lithium battery pack refers to the assembly and production of lithium batteries, also known as lithium battery packs. Lithium ion battery packs are widely used in the consumer electronics

Get a quote

How to Make a 12v 18650 Battery Pack from Scratch

Making your own custom 12v 18650 lithium-ion battery pack may sound intimidating. But I''m going to walk you through the entire process, step-by-step. Whether you

Get a quote

How to Assemble a Lithium-Ion Battery Pack with a

When connecting battery cells, nickel strips are typically the best option due to their low resistance and reliability for spot welding. To

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Get a quote

How Are Lithium Battery Packs Assembled?

The assembly process of lithium battery packs is crucial for ensuring their optimal performance, safety, and longevity. This article explores the key steps involved in lithium battery pack

Get a quote

Understanding the Battery Cell Assembly Process

The battery cell assembly process must continue to evolve to ensure that it remains a reliable, efficient, and sustainable method of storing

Get a quote

An Extremely Detailed 48V Lithium ion Battery Assembly Tutorial

So that''s the lithium battery assembly tutorial. Have you learned it all? SmartPropel pay high attention on the first-class technical craft, scientific lithium battery production and

Get a quote

How to Assemble a Lithium-Ion Battery Pack with a BMS Module:

When connecting battery cells, nickel strips are typically the best option due to their low resistance and reliability for spot welding. To understand why nickel strips are favored over

Get a quote

Beginner-Friendly Tips for Assembling Lithium Battery

Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Get a quote

Mastering the Art of Lithium Battery Pack Assembly: A

Through our comprehensive guide, you will become a master of the art of lithium battery pack assembly, understanding the key points and best practices at each step.

Get a quote

How to Build Your Own Battery Pack: A Step-by-Step Guide

Building your own battery pack can be an exciting and rewarding project, allowing you to customize power solutions for various applications, from electric bikes to solar energy

Get a quote

RELIABLE definition | Cambridge Essential American Dictionary

B1 able to be trusted or believed: a reliable car reliable information Opposite unreliable (Definition of reliable from the Webster''s Essential Mini Dictionary © Cambridge University Press)

Get a quote

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

In this step-by-step guide, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high-performance battery.

Get a quote

Lithium Battery Pack Assembly: A Comprehensive Guide

We integrate the Battery Management System (BMS) seamlessly into the assembly process as the intelligent heart of the battery pack. The

Get a quote

DIY Lithium Ion: A Guide To Making Your Own Battery

Learn how to create your own lithium-ion battery with this comprehensive DIY guide. Discover step-by-step instructions and essential tips for a successful project.

Get a quote

Complete Guide to Lithium Battery Pack Design and Assembly

Through scientific design and strict manufacturing control, the battery pack''s safety, reliability, and service life are well guaranteed. Compared to a single battery cell, a lithium

Get a quote

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

Get a quote

Optimal Lithium Battery Charging: A Definitive Guide

Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Get a quote

Lithium Battery Pack Assembly: A Comprehensive Guide

We integrate the Battery Management System (BMS) seamlessly into the assembly process as the intelligent heart of the battery pack. The BMS monitors and regulates the

Get a quote

Mastering the Art of Lithium Battery Pack Assembly: A

Through our comprehensive guide, you will become a master of the art of lithium battery pack assembly, understanding the key points and best

Get a quote

How to Build Your Own Battery Pack

Building your own battery pack is a rewarding project that allows you to create a customized power source for various devices, from electric vehicles to solar setups. Whether

Get a quote

Beginner-Friendly Tips for Assembling Lithium Battery Packs

Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Get a quote

6 FAQs about [Is it reliable to assemble lithium battery packs ]

Why is quality control important in a lithium battery pack assembly?

Consequently, this intricate step paves the way for efficient power transfer and optimal pack performance. Quality control is a cornerstone of the lithium battery pack assembly process.

How do you test a lithium battery pack?

Voltage and Current Testing: Use a multimeter to ensure the pack operates within safe parameters. Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations.

What is a high-performance lithium battery pack?

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

Why should you build a custom battery pack?

Building a custom battery pack offers both businesses and DIY enthusiasts the ability to tailor power solutions to their specific needs, whether for electric vehicles, robotics, drones, or energy storage systems. For businesses, it ensures optimal performance and longevity, critical in high-demand applications.

Can I use same cells in the same battery pack?

A: No, it's strongly recommended to use identical cells in the same battery pack. You should always use cells from the same manufacturer, with the same specifications and date code.

What is a lithium battery management system (BMS)?

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

Guess what you want to know

-

Two identical 24V lithium battery packs in Croatia

Two identical 24V lithium battery packs in Croatia

-

Commonly used lithium battery packs

Commonly used lithium battery packs

-

Can lithium battery packs be sent by EMS

Can lithium battery packs be sent by EMS

-

Are lithium batteries all small battery packs

Are lithium batteries all small battery packs

-

Currently lithium battery packs are generally charged using

Currently lithium battery packs are generally charged using

-

How wide should the nickel strip be for lithium battery packs

How wide should the nickel strip be for lithium battery packs

-

How many lithium iron phosphate battery packs are needed for 60v

How many lithium iron phosphate battery packs are needed for 60v

-

How many pieces are needed to assemble a 24v lithium battery pack

How many pieces are needed to assemble a 24v lithium battery pack

-

Are lithium battery packs safe in Burkina Faso

Are lithium battery packs safe in Burkina Faso

-

Which company produces the best lithium battery packs

Which company produces the best lithium battery packs

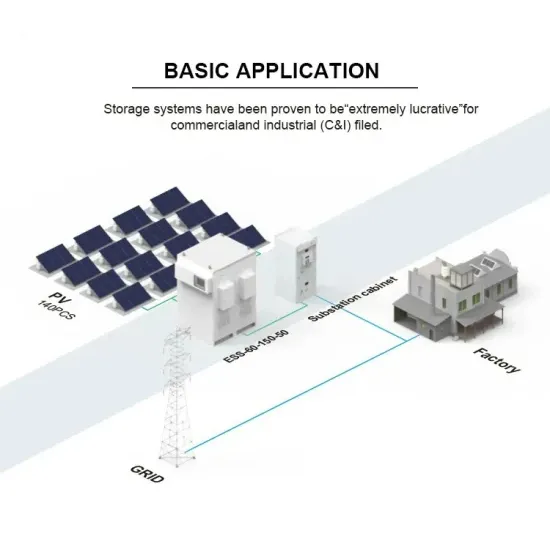

Industrial & Commercial Energy Storage Market Growth

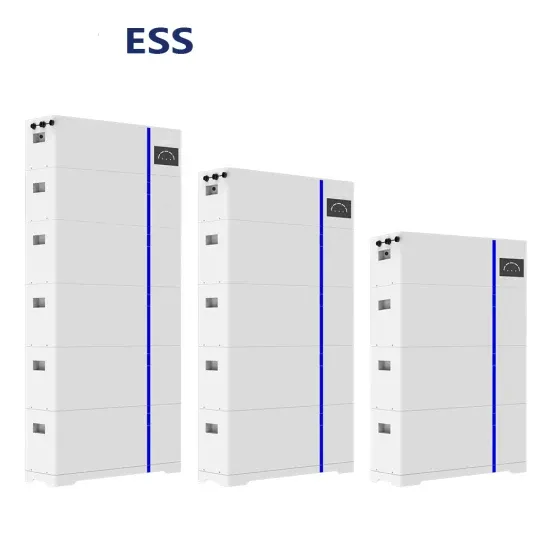

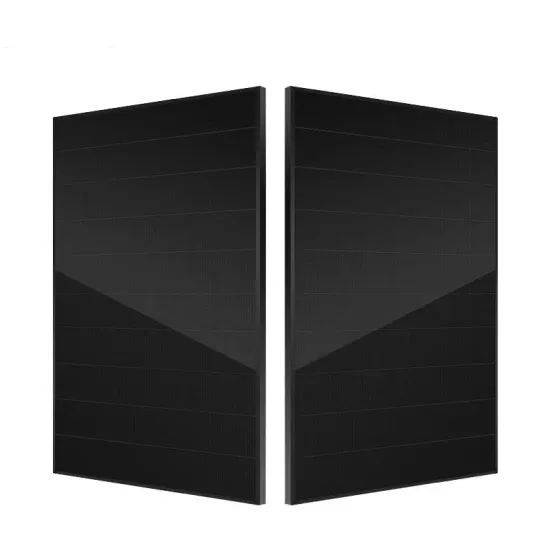

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

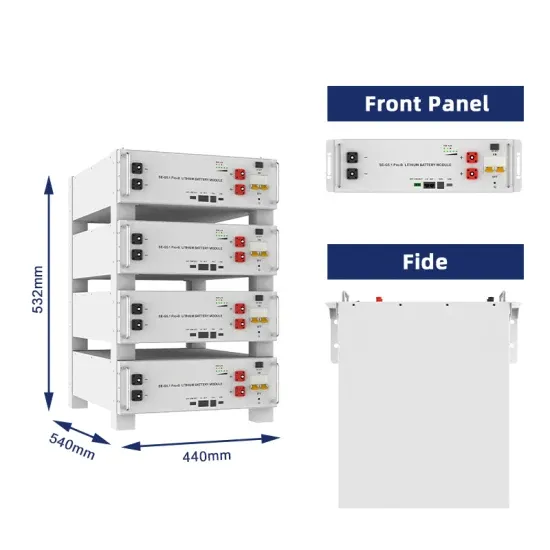

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.