Pure Nickel Strip or Nickel Plated Steel to DIY Battery

The width and material of the nickel strip should be selected according to the current of the lithium battery pack. In terms of material, there are two

Get a quote

Pure Nickel Strips for Lithium Battery Pack Welding 99.6

Pure Nickel Size and Current: Select the correct pure nickel strip configuration for the battery based on the battery pack output current. Different sizes of pure nickel strips can

Get a quote

HARFINGTON Nickel Strip 0.1mm x 8mm (9.8ft / Roll) Nickel

HARFINGTON Nickel Strip 0.1mm x 8mm (9.8ft / Roll) Nickel Plated Steel Strips for Lithium Battery Packs Car Nickel Tap for Cell Battery Pack Spot Welding and Soldering,

Get a quote

SUIDI Pure Nickel Strip for battery welding 18650 Nickel Strip 2P

Pure nickel strip,Only 99.96% pure nickel strips sale, the battery in the picture is for display only 18650 Nickel Strip 2P, 0.15mm (thickness) x 23mm (wide) x 18.5mm (Spacing)

Get a quote

How To Size Wire, Fuses, And Nickel Strip Current Rating

For 10mm strips I calculate the ratios. By my math,14 amps on a .2mm x 10mm strip is acceptable. You could double that strip up for your series connections. As for your # 2,

Get a quote

Current Carrying Capability of Nickel Strips

I''m trying to minimize the thickness of my nickel strips, by evaluating how wide I can make my strips. Typical cheap spot welders have difficulty spot welding strips thicker than

Get a quote

How To Size Wire, Fuses, And Nickel Strip Current Rating

The most commonly available pure nickel strips are 7mm wide, though 10mm is readily available. There are some 47mm strips, but there is a large air gap in the middle.

Get a quote

Nickel Battery Strip

Explore a wide range of our Nickel Battery Strip selection. Find top brands, exclusive offers, and unbeatable prices on eBay. Shop now for fast shipping and easy returns!

Get a quote

Best Conductors to Use For Battery Pack

If you are interested in getting into battery building, you may be wondering which metal to use for building battery packs. If you are building a

Get a quote

HARFINGTON Nickel Strip 0.1mm x 8mm (16.4ft / Roll) Nickel

HARFINGTON Nickel Strip 0.1mm x 8mm (16.4ft / Roll) Nickel Plated Steel Strips for Lithium Battery Packs Car Nickel Tap for Cell Battery Pack Spot Welding and Soldering,

Get a quote

Nickel Strips for Lithium Batteries: Essential Connectors for Safe

Standard option for most battery packs. Available in various widths and thicknesses (e.g., 0.1 mm, 0.15 mm, 0.2 mm). Used to connect cells in 2P or 3P parallel formats. Pre-cut for efficient,

Get a quote

Nickel Strip ratings

The image is of one of the 6s16p packs and does not offer the best view I understand, but hopefully you can see the copper 8awg wiring along the top running the length

Get a quote

Nickel Strip Dilemma: Single or Double Layer for My Battery Pack?

According to my favorite wire size charge that''s in the range of 30-35mm squared of copper type metal. .15mm * 27mm = 4.05mm squared which is more like 50a max. based on

Get a quote

How to Choose the Right Pure Nickel Strip Sizes for the DIY Battery

To choose the right size of nickel strip, you need to consider the following factors: The amount of current your battery pack will deliver is a crucial factor in determining the

Get a quote

99.9% Pure nickel strip for lithium ion battery pack

Product description: Pure nickel strip has good gloss, ductility, solderability, conductivity and corrosion resistance. It is used as a precision conductor to

Get a quote

How to Design Nickel strip | Single & Double Layer | For your

In this comprehensive tutorial, we dive into the essential steps for designing single and double nickel strips for lithium battery packs.

Get a quote

What size nickel strips should you use?

To determine the appropriate size of nickel strips for your battery pack, you can use an online calculator or refer to a manufacturer''s datasheet. The calculator will take into

Get a quote

How to Design Nickel strip | Single & Double Layer | For your Lithium

In this comprehensive tutorial, we dive into the essential steps for designing single and double nickel strips for lithium battery packs.

Get a quote

Battery Pack Design

Since I''m limited to one cell wide strip of at most 21 mm, sine 21700 cells are 21 mm wide. Need some sort of air gap, so really the most wide I can do 15 mm, and stack as many

Get a quote

HARFINGTON 100pcs Pure Nickel Strip 0.1 x 4 x 100mm 99.6% Nickel

HARFINGTON 100pcs Pure Nickel Strip 0.1 x 4 x 100mm 99.6% Nickel Solid Pure Nickel Strips for Lithium Battery Packs Car Nickel Solder Tap for Cell Battery Pack Spot

Get a quote

Everything You Need to Know About Sizing Nickel

Learn how to size nickel strips for batteries, including thickness, width, and material selection, to ensure safe, efficient, and durable battery

Get a quote

Help with nickel strip sizing

For 10mm strips I calculate the ratios. By my math,14 amps on a .2mm x 10mm strip is acceptable. You could double that strip up for your series connections. As for your # 2,

Get a quote

Pure Nickel Strip Roll for Battery Spot Welding

Description This premium Pure Nickel Strip is crafted with 99.6% purity, offering outstanding conductivity and corrosion resistance—making it the ideal choice for lithium-ion battery pack

Get a quote

Pure Nickel Strip or Nickel Plated Steel to DIY Battery Pack?

The width and material of the nickel strip should be selected according to the current of the lithium battery pack. In terms of material, there are two commonly used nickel strips: pure nickel strips

Get a quote

Figuring nickel strip size for DIY?

Plan: Two 48V batteries made of 32650 LiFePO4s @ 6 aH with this configuration: 16s6p (96 cells/battery) 52.8 nominal volts Paralleled in 48V system with ~80V panel system

Get a quote

How to Choose the Right Pure Nickel Strip Sizes for the DIY

To choose the right size of nickel strip, you need to consider the following factors: The amount of current your battery pack will deliver is a crucial factor in determining the

Get a quote

Everything You Need to Know About Sizing Nickel Strips for

Learn how to size nickel strips for batteries, including thickness, width, and material selection, to ensure safe, efficient, and durable battery pack performance.

Get a quote

6 FAQs about [How wide should the nickel strip be for lithium battery packs ]

How to choose a nickel strip for a lithium battery?

The width and material of the nickel strip should be selected according to the current of the lithium battery pack. In terms of material, there are two commonly used nickel strips: pure nickel strips and nickel plated steel. What is the difference between their performance and actual use?

What size nickel strips should I buy?

So, keep that in mind when shopping for nickel strips. The most commonly available pure nickel strips are 7mm wide, though 10mm is readily available. There are some 47mm strips, but there is a large air gap in the middle. If you need more current, you could always spot-weld 2 to 3 layers of nickel strips on top of each other for more capacity.

How much current can a nickel strip withstand?

For nickel-plated steel, its calculation formula is usually calculated according to 7A/mm², that is to say, the maximum continuous overcurrent of nickel-plated steel with a thickness of 0.15mm*7mm is 7*0.15*7=7.35A. It can be seen that the current that a pure nickel strip can withstand is about 1.5 times that of nickel plated steel.

What is nickel strip?

Nickel strip is a material often used in series and parallels lithium battery packs. The width and material of the nickel strip should be selected according to the current of the lithium battery pack. In terms of material, there are two commonly used nickel strips: pure nickel strips and nickel plated steel.

What size nickel strip should a welder use?

Most low-cost welders have a hard time around 0.15mm, and most cannot even work with 0.20mm, even on the highest settings. So, keep that in mind when shopping for nickel strips. The most commonly available pure nickel strips are 7mm wide, though 10mm is readily available. There are some 47mm strips, but there is a large air gap in the middle.

What material is used to connect lithium ion batteries?

Nickel is the preferred conductor to connect lithium-ion battery cells together. Nickel strip is the most common material used in lithium-ion battery construction because it is easy to spot weld and has excellent anti-corrosive properties while having a relatively low cost. 99.6% pure nickel strip in a variety of lengths, widths, and thicknesses.

Guess what you want to know

-

How many inverters are needed for lithium battery packs

How many inverters are needed for lithium battery packs

-

How many lithium iron phosphate battery packs are needed for 60v

How many lithium iron phosphate battery packs are needed for 60v

-

How much does a 380v three-phase lithium battery pack cost

How much does a 380v three-phase lithium battery pack cost

-

How many strings are there for a 36v lithium battery pack

How many strings are there for a 36v lithium battery pack

-

How to install lithium batteries in battery cabinet

How to install lithium batteries in battery cabinet

-

How to replace lithium batteries in Egypt outdoor communication battery cabinets

How to replace lithium batteries in Egypt outdoor communication battery cabinets

-

How much does lithium battery for energy storage cost in Armenia

How much does lithium battery for energy storage cost in Armenia

-

Malaysia produces solar lithium battery packs

Malaysia produces solar lithium battery packs

-

How long does it take to charge a lithium battery pack

How long does it take to charge a lithium battery pack

-

Production of outdoor lithium battery packs

Production of outdoor lithium battery packs

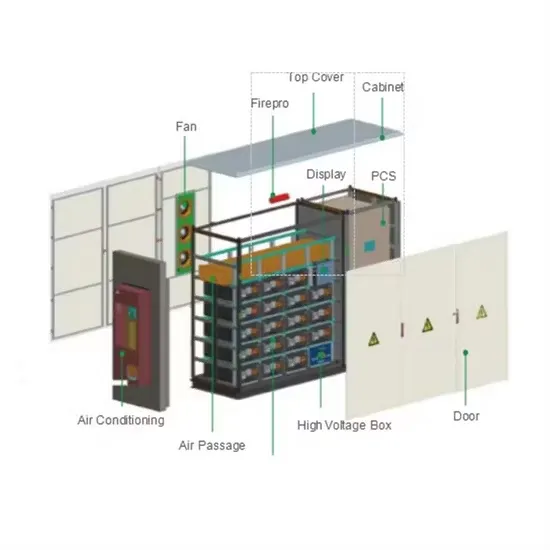

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.