Global Lithium Battery for Communication Base Stations Market

The Lithium Battery for Communication Base Stations market has emerged as a critical segment within the telecommunications industry, driven by the increasing demand for reliable and

Get a quote

what are the uses of energy storage batteries for communication base

【MANLY Battery】Lithium batteries for communication base stations The advent of the 5G era has accelerated the fire of lithium batteries in communication base stations. China Tower

Get a quote

What Safety Features Ensure Reliability in Telecom Lithium Batteries

Telecom lithium batteries integrate advanced safety mechanisms like thermal management, overcharge protection, and flame-retardant materials to prevent failures.

Get a quote

Does the communication base station energy storage lithium

Are lithium batteries suitable for a 5G base station? 2) The optimized configuration results of the three types of energy storage batteries showed that since the current tiered-use of lithium

Get a quote

Lithium-Ion Batteries Hazards

Lithium-ion (Li-ion) and lithium polymer (LiPo) batteries have been the cause of several high-profile fires and many routine fires across the nation. Let''s review the hazards these batteries

Get a quote

Communication Base Station Energy Storage Lithium Battery

The Communication Base Station Energy Storage Lithium Battery market is experiencing robust growth, driven by the increasing demand for reliable and efficient power

Get a quote

Lithium-Ion Batteries: How to Overcome Current and

While the growth in lithium-ion batteries continues, other types of chemistries for batteries are being investigated, Butts says, referencing a

Get a quote

A review of lithium-ion battery safety concerns: The issues,

Thus, the environment in which the battery operates also plays a significant role in battery safety. Safety standards and related tests have been developed to analyze battery

Get a quote

Battery technology for communication base stations

Feasibility study of power demand response for 5G base station In order to ensure the reliability of communication, 5G base stations are usually equipped with lithium iron phosphate cascade

Get a quote

Use of Batteries in the Telecommunications Industry

ATIS Standards and guidelines address 5G, cybersecurity, network reliability, interoperability, sustainability, emergency services and more...

Get a quote

What Safety Features Ensure Reliability in Telecom Lithium

Telecom lithium batteries integrate advanced safety mechanisms like thermal management, overcharge protection, and flame-retardant materials to prevent failures.

Get a quote

Lithium-Ion Batteries: How to Overcome Current and Future Safety

While the growth in lithium-ion batteries continues, other types of chemistries for batteries are being investigated, Butts says, referencing a Louisiana State University group

Get a quote

What Powers Telecom Base Stations During Outages?

Telecom batteries for base stations are backup power systems using valve-regulated lead-acid (VRLA) or lithium-ion batteries. They ensure uninterrupted connectivity

Get a quote

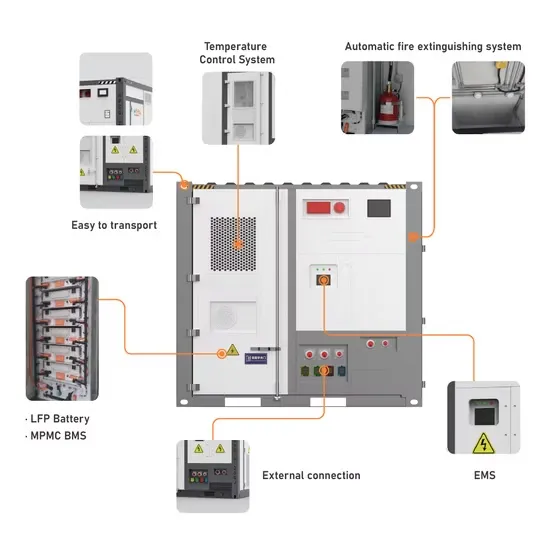

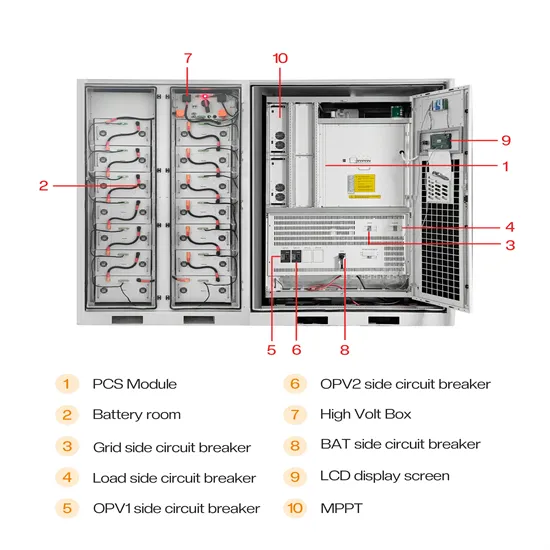

Battery Energy Storage Systems: Main Considerations for Safe

Battery Energy Storage Systems, or BESS, help stabilize electrical grids by providing steady power flow despite fluctuations from inconsistent generation of renewable

Get a quote

Can telecom lithium batteries be used in 5G telecom base stations?

Integrating lithium batteries into existing 5G base station power systems may require some modifications. Operators need to ensure that the battery''s voltage, capacity, and

Get a quote

Battery for Communication Base Stations Market Size and

The global market for batteries in communication base stations is experiencing robust growth, projected to reach $1692 million in 2025 and maintain a Compound Annual

Get a quote

Communication Base Station Energy Storage Lithium Battery

The communication base station energy storage lithium battery market is experiencing robust growth, driven by the increasing demand for reliable and efficient power backup for 5G and

Get a quote

A review of lithium-ion battery safety concerns: The issues,

Lithium-ion batteries (LIBs) with excellent performance are widely used in portable electronics and electric vehicles (EVs), but frequent fires and explosions limit their further and

Get a quote

What Are the Essential Telecom Battery Safety Guidelines?

Key practices include proper installation, regular maintenance, compliance with standards like IEEE and NEC, and safe disposal of lead-acid or lithium-ion batteries.

Get a quote

Use of Batteries in the Telecommunications Industry

The Alliance for Telecommunications Industry Solutions is an organization that develops standards and solutions for the ICT (Information and Communications Technology) industry.

Get a quote

Lithium Iron Batteries for Telecommunications Base Stations

REVOV''s lithium iron phosphate (LiFePO4) batteries are ideal telecom base station batteries. These batteries offer reliable, cost-effective backup power for communication networks. They

Get a quote

6 FAQs about [Safety issues of lithium batteries in communication base stations]

What are the OSHA standards for lithium-ion batteries?

While there is not a specific OSHA standard for lithium-ion batteries, many of the OSHA general industry standards may apply, as well as the General Duty Clause (Section 5(a)(1) of the Occupational Safety and Health Act of 1970). These include, but are not limited to the following standards:

Are lithium battery fires a safety concern?

While BESS technology is designed to bolster grid reliability, lithium battery fires at some installations have raised legitimate safety concerns in many communities. BESS incidents can present unique challenges for host communities and first responders:

Are lithium-ion batteries safe?

Lithium-ion batteries (LIBs) with excellent performance are widely used in portable electronics and electric vehicles (EVs), but frequent fires and explosions limit their further and more widespread applications. This review summarizes aspects of LIB safety and discusses the related issues, strategies, and testing standards.

Why is proper lithium-ion battery storage important?

Proper lithium-ion battery storage is critical for maintaining optimum battery performance and reducing the fire and explosion risk. Following are some best practices that, if correctly followed, will reduce the risk of fire and explosion of stored batteries.

Are lithium ion batteries flammable?

Some of these electrolytes are flammable liquids and requirements within OSHA’s Process Safety Management standard may apply to quantities exceeding 10,000 lb. Many of the chemicals used in lithium-ion battery manufacturing have been introduced relatively recently.

What happens if a lithium ion battery pack fails?

Lithium-ion battery packs of any scale can off-gas when they fail. A failure of an e-mobility device containing a lithium-ion battery pack in a garage can lead to deflagration. This low-speed explosion produces about 3 psi of pressure inside the garage.

Guess what you want to know

-

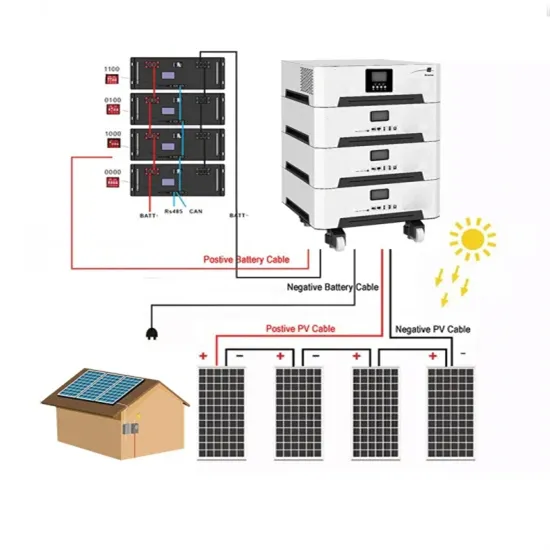

Solar processing of lithium batteries for communication base stations

Solar processing of lithium batteries for communication base stations

-

Communication base stations have lithium iron phosphate batteries

Communication base stations have lithium iron phosphate batteries

-

Lithium titanate batteries for communication base stations

Lithium titanate batteries for communication base stations

-

The cost of installing batteries for communication base stations in Sao Tome and Principe

The cost of installing batteries for communication base stations in Sao Tome and Principe

-

Lithium battery power supply for communication base stations

Lithium battery power supply for communication base stations

-

What is the construction scope of liquid flow batteries for communication base stations

What is the construction scope of liquid flow batteries for communication base stations

-

Where are the lead-acid batteries for communication base stations in Uzbekistan

Where are the lead-acid batteries for communication base stations in Uzbekistan

-

Production of lithium battery packs for communication base stations

Production of lithium battery packs for communication base stations

-

Commercial use of energy storage batteries for communication base stations

Commercial use of energy storage batteries for communication base stations

-

Can Peru manufacture batteries for communication base stations

Can Peru manufacture batteries for communication base stations

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.