Voltage Multiplier Calculator: Boost Your Voltage Easily!

In electronics, sometimes you need a voltage that''s higher than your power supply can deliver — but without using a heavy transformer. That''s where a Voltage Multiplier Circuit

Get a quote

Capacitor Voltage Booster Circuit

This electronics video tutorial explains how to make a simple capacitor voltage booster circuit. Here are some other videos that explains how to boost the v...

Get a quote

Changing inverter voltage output?

Modern switching regulated power supplies will still pull about the same power by pulling less current at the higher voltage, but an old style linear regulator will have to drop the

Get a quote

Working with higher voltages, Part 2: Voltage multipliers

Q: What if I need a negative high voltage from a multiplier? A: That''s the only easy thing about high-voltage multipliers: simply reverse the polarities of all the multiplier diodes

Get a quote

X10 Voltage Multiplier use capacitor

The Voltage Multiplier is a type of diode rectifier circuit which can produce an output voltage many times greater than of the applied input voltage Although it is usual in electronic circuits to

Get a quote

Voltage Multipliers

Despite they have some limitations such as loading times and complexity the advantages of voltage multipliers make them best tools for designers who are seeking efficient

Get a quote

Output impedance of voltage multiplier/inverter

To use it, you need the no-load secondary voltage and the effective resistance. It includes a voltage-doubler rectifier as a possible circuit; that would solve half of your circuit

Get a quote

Have you ever heard of an Amp multiplier? : r

The Ben Eater video is about a charge pump to easily double the supply voltage. Not really useful for your application In your application, you have batteries which can store a lot of energy but

Get a quote

How do we increase the AC output voltage on a Multiplus 48/5000/70 inverter

The maximum voltage you can adjust this to is 245V, so hopefully that''s close enough to what you need. Please be exceptionally careful and understand that doing this

Get a quote

5v to 12v converter – Simple DC voltage booster circuit

The circuit below is shows 6 volt input, however you can use it with input voltage range of 4.5 volt up-to 9 volt. One thing to remember, we can increase and decrease output

Get a quote

Everything You Need To Know About Voltage Multipliers

In theory, the multiplier''s output is an integer multiple of the AC peak input voltage. While voltage multipliers can function with any input

Get a quote

Does the voltage continue to increase if the multiplier continues

The voltage will increase but there are diminishing returns that come from adding more stages. There is leakage and the available output current decreases with each added

Get a quote

How do we increase the AC output voltage on a Multiplus

The maximum voltage you can adjust this to is 245V, so hopefully that''s close enough to what you need. Please be exceptionally careful and understand that doing this

Get a quote

A simplified scheme of voltage multiplier supplied by an inverter

Power regulation is possible by changing the inverter supply voltage (amplitude modulation, AM) or pulse density modulation (PDM). During one period of the inverter operation for the...

Get a quote

Power Tips: Multiply Your Output Voltage

Diode forward voltage drops and small capacitance values reduce the output voltage as the load current increases. However, knowing this limitation, a voltage multiplier can boost the output

Get a quote

Changing inverter voltage output?

The power goes up at a square of the voltage in a resistive circuit. 120 to 125 volts is only a 4.1667% increase, but the wattage going from 500 to 542.53 is an 8.5% increase in

Get a quote

Voltage Multipliers (Doublers, Triplers, Quadruplers,

A voltage multiplier of cascaded half-wave doublers of arbitrary length is known as a Cockcroft-Walton multiplier, as illustrated in Figure 10. This multiplier is

Get a quote

Voltage Multiplier Cell-Based Quasi-Switched Boost Inverter with

A novel single-phase single-stage voltage multiplier cell-based quasi-switched boost inverter (VMC-qSBI) is proposed in this paper. By adding the voltage multiplier cell to

Get a quote

Working with higher voltages, Part 2: Voltage multipliers

Q: What if I need a negative high voltage from a multiplier? A: That''s the only easy thing about high-voltage multipliers: simply reverse the

Get a quote

Advanced Dual Boost Inverter with High Voltage Gain DC to

Abstract: A novel dual boost inverter with high voltage gain DC to DC converter for PV system application is analyzed in this paper. This new topology comprises of modified Dickson charge

Get a quote

Increase Output Voltage With A Voltage Multiplier

A simple boost converter with a voltage multiplier can solve these issues. It uses a standard inductor, low-voltage components, and can provide

Get a quote

A simplified scheme of voltage multiplier supplied by an inverter

During one period of the inverter operation for the multiplier from Fig. 1 (a) (voltage doubler, n = 2), 2-time intervals can be distinguished (Fig. 2).

Get a quote

Increase Output Voltage With A Voltage Multiplier

A simple boost converter with a voltage multiplier can solve these issues. It uses a standard inductor, low-voltage components, and can provide a large boost ratio in

Get a quote

What are some ways to improve a voltage multiplier?

As several people suggested, something called "push-pull" was a quick fix here. A CMOS inverter with separately-driven gates makes the charge pump much more effective:

Get a quote

6 FAQs about [Can I increase the voltage multiplier if the inverter voltage is insufficient ]

What is a voltage multiplier?

A: These voltage multipliers are specialized rectifier circuits which develop an output voltage which is (in theory) an integer times the AC peak input, for example, ×2, ×3, or ×4 times the AC peak input value. They are usually configured as a stack of half or full-wave rectifiers. Q: Can you show an example?

What are the advantages and disadvantages of voltage multiplier circuit?

Given Below Are Advantages and Disadvantages of Voltage Multiplier Circuit. It is helpful for Compact Design. It is used for High Voltage Output. It is used for Simple Construction. It is used because of its Low Cost. It is used because of its Efficiency in Specific Applications. It is only Limited to the Low Power Applications.

What is a boost converter with a voltage multiplier?

A simple boost converter with a voltage multiplier can solve these issues. It uses a standard inductor, low-voltage components, and can provide a large boost ratio in discontinuous mode (DCM). How does a boost converter with a voltage doubler work? The image below details the two operating modes of a boost converter with a voltage doubler.

Can multiplier stages be scaled up?

The multiplier stages in this circuit can be scaled up as needed to decrease voltage stress further for the same output voltage, or to simply increase the output voltage. Below are the switching waveforms present at TP1, TP2, and TP3 in the example circuit at full load and at 15 V input.

Can a high-voltage multiplier produce a negative voltage multiplier?

A: That’s the only easy thing about high-voltage multipliers: simply reverse the polarities of all the multiplier diodes and capacitors to produce a negative voltage multiplier. Q: Sounds easy enough, but is it? A: Absolutely not!

Can a 100 volt circuit be scaled up?

This allows the use of common 100 V components, providing an adequate 67% derating. The multiplier stages in this circuit can be scaled up as needed to decrease voltage stress further for the same output voltage, or to simply increase the output voltage.

Guess what you want to know

-

Can an inverter increase DC voltage

Can an inverter increase DC voltage

-

96v inverter to increase voltage

96v inverter to increase voltage

-

Voltage after three-phase inverter

Voltage after three-phase inverter

-

Inverter voltage keeps increasing

Inverter voltage keeps increasing

-

Amorphous machine inverter high voltage

Amorphous machine inverter high voltage

-

Inverter voltage fine-tuning

Inverter voltage fine-tuning

-

Is it better to use a higher voltage inverter

Is it better to use a higher voltage inverter

-

Inverter output voltage returns to zero

Inverter output voltage returns to zero

-

Inverter upper and lower voltage

Inverter upper and lower voltage

-

Use inverter when voltage is high

Use inverter when voltage is high

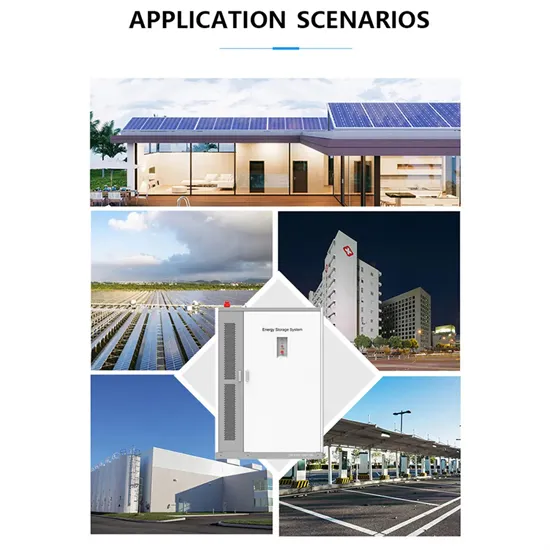

Industrial & Commercial Energy Storage Market Growth

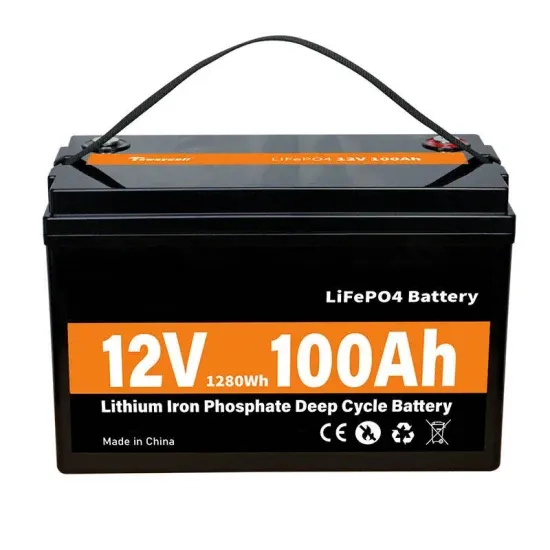

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.