Battery Packs In Series Or Parallel: Key Differences And Wiring

Connecting battery packs in series increases the output voltage while keeping the capacity the same. In contrast, wiring them in parallel boosts the total capacity without

Get a quote

Ultimate Guide of LiFePO4 Lithium Batteries in Series & Parallel

Unlock the ultimate guide to using LiFePO4 lithium batteries in series and parallel. Learn configurations, benefits, and tips for optimal performance!

Get a quote

How to Connect Lithium Batteries in Series and Parallel?

In this article, we''ll explore the basics and provide detailed, step-by-step instructions on how to connect lithium batteries in series, parallel, and

Get a quote

Multiple Packs 12V 100Ah LiFePO4 Lithium Battery

Dr.Prepare''s 12V 100Ah LiFePO4 Lithium Iron Phosphate Battery comes with an integrated BMS for low temperature cut-off protection during charging and

Get a quote

LiFePO4 Lithium Batteries in Series VS Parallel Connection

Series connection of LiFePO4 batteries involves linking multiple cells in a sequence to boost the total voltage output. In this setup, the positive terminal of one cell

Get a quote

How to Connect Lithium Batteries in Series and Parallel?

A series-parallel connection combines both configurations to increase both voltage and capacity. For example, connecting four 3.7V 100mAh lithium cells in a series-parallel

Get a quote

LiFePO4 Lithium Batteries in Series VS Parallel

Series connection of LiFePO4 batteries involves linking multiple cells in a sequence to boost the total voltage output. In this setup, the positive

Get a quote

What are the implications of connecting lithium battery packs in series?

The concern with series-connected batteries of any type is uneven charge/discharge rates within the string of cells. This can cause overcharging of some cells,

Get a quote

How Do You Balance Lithium Battery Packs In Series?

To balance lithium batteries in series, you would need to charge the batteries individually to the same charge voltage. Unlike cells in series that can be kept balanced by a

Get a quote

How to Connect Lithium Batteries in Series and Parallel?

In this article, we''ll explore the basics and provide detailed, step-by-step instructions on how to connect lithium batteries in series, parallel, and series-parallel configurations.

Get a quote

How Many Cells in a Lithium Battery Pack? A Complete Guide to

LiFePO4, or lithium iron phosphate, is a type of lithium battery known for its stability and safety. A LiFePO4 battery pack usually also comprises four cells connected in

Get a quote

Lithium Battery Series & Parallel Operation | Fact Sheets

Check out our fact information sheet on the Lithium Battery Series and Parallel Operation. Get a breakdown of the basics, BMS, Parallel Operation and more!

Get a quote

Ultimate Power: Lithium-Ion Batteries In Series

The common notation for battery packs in parallel or series is XsYp – as in, the battery consists of X cell "stages" in series, where each stage

Get a quote

BU-302: Series and Parallel Battery Configurations

Four 12.8V-100AH lithium batteries connected in series becomes a 51.2V-100AH battery bank with 5120 watts of stored energy potential to 100% DOD. Connecting batteries in Series

Get a quote

Lithium Series, Parallel and Series and Parallel

Four 12.8V-100AH lithium batteries connected in series becomes a 51.2V-100AH battery bank with 5120 watts of stored energy potential to 100% DOD. Connecting batteries in Series

Get a quote

How to Correctly Connect Batteries in Series and Parallel Formula

For instance, a laptop battery may consist of four 3.6V lithium-ion cells connected in series, reaching a total voltage of 14.4V. Then, two sets of these series-connected cells are

Get a quote

What are the implications of connecting lithium battery packs in

The concern with series-connected batteries of any type is uneven charge/discharge rates within the string of cells. This can cause overcharging of some cells,

Get a quote

How to Correctly Connect Batteries in Series and Parallel Formula

Understanding how to properly connect batteries in series and parallel formula might seem straightforward, but by adhering to a few simple guidelines, one can avoid

Get a quote

A Beginner''s Guide to Connecting LiFePO4 Batteries

Battery balancing refers to the process of equalizing the charge across multiple cells or batteries connected in series. During balanced

Get a quote

Can Batteries with the Same Voltage Be Connected in Series?

When designing or expanding battery-powered systems, a common question arises: Can two battery packs with the same voltage be connected in series? The short answer is yes, but with

Get a quote

Investigation of series-parallel connections of multi-module

Large-format Lithium-ion battery packs consist of the series and parallel connection of elemental cells, usually assembled into modules. The required voltage and capacity of the battery pack

Get a quote

Microsoft Word

Figure 2 shows two 12-volt batteries connected in series. The important things to note about a series connection are: 1) The battery voltages add together to determine the battery pack

Get a quote

What are the implications of connecting lithium battery packs in series?

0 I would like to connect 13S (48V nominal/~25Ah) lithium battery pack in series with a pack of 10 lithium cells (3.7V nominal/~30Ah) in order to get a 14S battery without

Get a quote

How to Correctly Connect Batteries in Series and

For instance, a laptop battery may consist of four 3.6V lithium-ion cells connected in series, reaching a total voltage of 14.4V. Then, two sets of

Get a quote

Series and Parallel Configuration of Lithium Battery

Using the series and parallel configuration, you can design the more voltage and higher capacity battery pack with a standard cell size.

Get a quote

BU-302: Series and Parallel Battery Configurations

Laptop batteries commonly have four 3.6V Li-ion cells in series to achieve a nominal voltage 14.4V and two in parallel to boost the capacity from 2,400mAh to 4,800mAh. Such a

Get a quote

How to Connect 4 Batteries in Series

Connecting 4 batteries in series is a straightforward process that helps increase voltage for devices that require higher power. This method involves linking the positive

Get a quote

Guess what you want to know

-

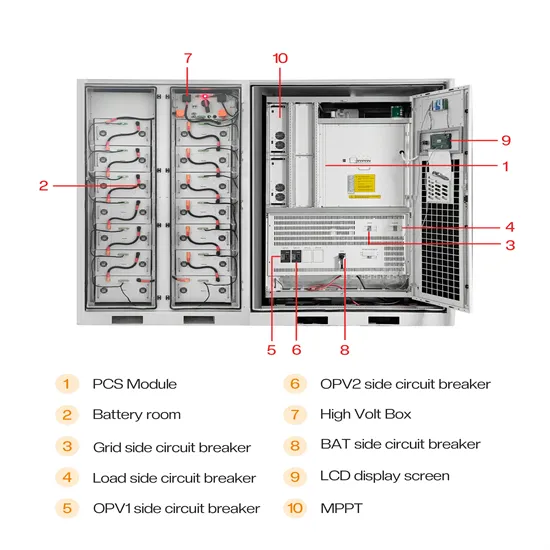

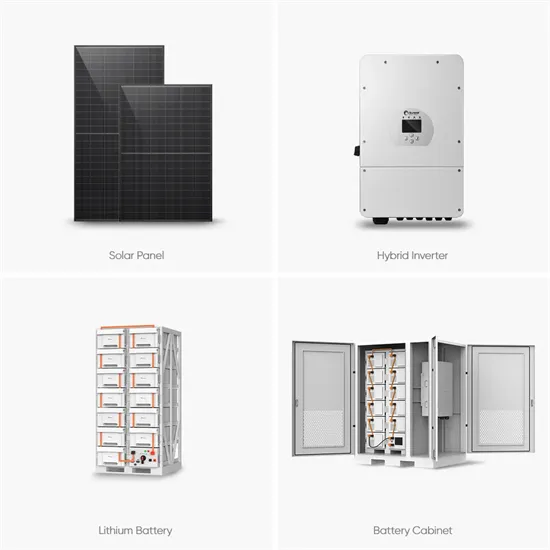

Lithium battery station cabinets connected in series

Lithium battery station cabinets connected in series

-

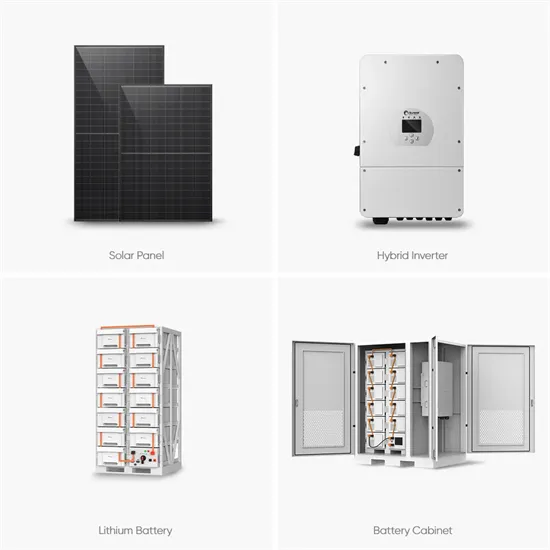

Lithium battery packs in series and parallel

Lithium battery packs in series and parallel

-

Production of lithium battery packs for communication base stations

Production of lithium battery packs for communication base stations

-

Lithium-ion batteries and lithium battery packs

Lithium-ion batteries and lithium battery packs

-

Production of outdoor lithium battery packs

Production of outdoor lithium battery packs

-

Battery photovoltaic panels connected in series

Battery photovoltaic panels connected in series

-

Can high energy lithium battery packs be charged

Can high energy lithium battery packs be charged

-

Focus on customization of lithium iron phosphate battery packs

Focus on customization of lithium iron phosphate battery packs

-

Lithium battery packs can be exported

Lithium battery packs can be exported

-

Are lithium battery packs safe in Burkina Faso

Are lithium battery packs safe in Burkina Faso

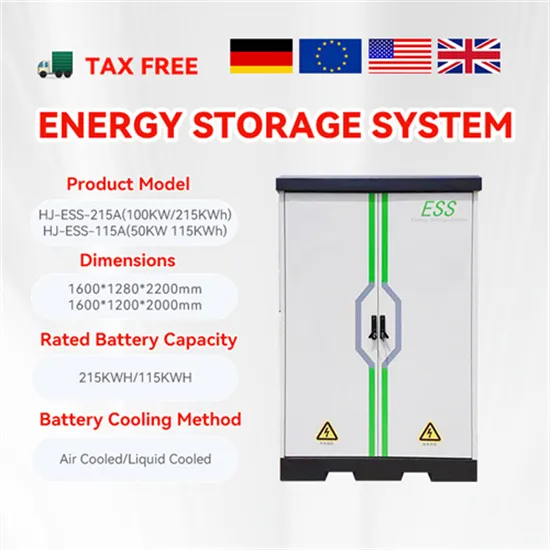

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.