Wind power

Wind power is the use of wind energy to generate useful work. Historically, wind power was used by sails, windmills and windpumps, but today it is mostly used to generate electricity. This

Get a quote

New Technologies in Auxiliary Propulsions | SpringerLink

In the following, the definition and ideas behind various technologies listed in Table 1 will be briefly presented. More focus will be put on the technologies using wind power as

Get a quote

Ancillary services from wind turbines: automatic

Abstract. Wind turbines possess the technical ability to provide various ancillary services to the electrical grid. Despite this, renewable generators such as wind

Get a quote

Analysis of Wind Turbine Equipment Failure and

Power generation from wind farms is growing rapidly around the world. In the past decade, wind energy has played an important role in

Get a quote

FAQ 101: The Great Equipment That We Use To Set Up For Wind

By ensuring that each project is equipped with the best turbines, electrical systems, control technologies, and installation equipment, JMS Energy offers unmatched services

Get a quote

Power electronics in wind generation systems

This Review discusses the current capabilities and challenges facing different power electronic technologies in wind generation systems from single turbines to the system

Get a quote

Wind Farm Backup Generators

To orientate towards the wind, the generators require auxiliary power. If there is no electrical network available, the generator sets must take over the auxiliary power supply to these

Get a quote

B.4.3 Auxiliary systems | Guide to a floating offshore wind farm

Also required are a control room, health and welfare and refuge for visiting crews, clean and black water systems, fuel tanks, LV power supplies, navigational aids, and safety systems.

Get a quote

Auxiliary Power Consumption

The auxiliary power consumption and line loss together accounted for 6% of the gross generation, which will be subtracted in the calculation of net electricity to access grid from the wind farm.

Get a quote

Advanced wind turbine protection and control system

KEy BEnEFITS Complete wind generator protection, control, metering and • Reduced system event analyzing time and cost through monitoring in a single device integrated Sequence of

Get a quote

Auxiliary Power Supply for Generator Sets in Wind and Solar

In wind energy fields, an auxiliary power supply can be used to power essential equipment such as control systems, lighting, and heating elements. This ensures that the wind turbines can

Get a quote

Wind Power Generation Training System | DOLANG

The wind power generation training system consists of the following: wind turbine, aero vane, adjustable speed blower, charge controller, batteries, off-grid

Get a quote

Design and Comparison of Auxiliary Resonance controllers for

Full converter-based wind power generation (FCWG, e.g., a permanent magnet synchronous generator (PMSG)), though normally considered to be decoupled from the external power grid

Get a quote

FAQ 101: The Great Equipment That We Use To Set

By ensuring that each project is equipped with the best turbines, electrical systems, control technologies, and installation equipment, JMS

Get a quote

FAQ 101: The Great Equipment That We Use To Set Up For Wind

Because of our fantastic reputation in wind energy design, many ask us about the equipment that we use to set up for wind energy. As the world shifts towards sustainable

Get a quote

Amazon : CRYBY Vertical Wind Generator, 500W Wind

POWERFUL AND EFFICIENT: This wind generator uses spiral blades with an aerodynamic shape and an auxiliary wind turbine to further enhance its performance for stable

Get a quote

Protection of Wind Electric Plants

Much of the equipment found in a wind powered plant is common to many electric distribution systems – busbars, cables, transformers, and capacitor banks, for example – so references

Get a quote

Essential Equipment Used in Wind Power Generation Systems: A

Let''s cut through the technical jargon and explore the real MVPs behind wind power generation systems. From colossal rotors to smart tech that''d make Einstein nod in approval, we''re

Get a quote

Amazon : CRYBY Vertical Wind Generator, 500W Wind Turbine Generator

POWERFUL AND EFFICIENT: This wind generator uses spiral blades with an aerodynamic shape and an auxiliary wind turbine to further enhance its performance for stable

Get a quote

An Introduction to Electrical Generators for Power Plants

The distinguishing feature of a unit type station power system is that the generator and unit auxiliary transformer are permanently connected together at generator voltage and the station

Get a quote

Wind Power Plant Evaluation Naval Auxiliary Landing Field,

The purpose of this report is to evaluate the wind power benefits and impacts to the SCI power system, including energy savings, emissions reduction, system stability, and decreased naval

Get a quote

Wind Farm Backup Generators

To orientate towards the wind, the generators require auxiliary power. If there is no electrical network available, the generator sets must take over the auxiliary

Get a quote

Modeling and Simulation of Wind Solar Hybrid System

Abstract This article is a simulation, designing and modeling of a hybrid power generation system based on nonconventional (renewable) solar photovoltaic and wind turbine

Get a quote

6 FAQs about [Wind power generation system auxiliary equipment]

What equipment is needed to deploy a wind energy system?

The deployment of a wind energy system involves a confluence of cutting-edge technology and heavy machinery. Here are some essential pieces of equipment involved in the set-up process: Wind Turbines: Why are they important? Wind turbines are the heart of any wind energy system.

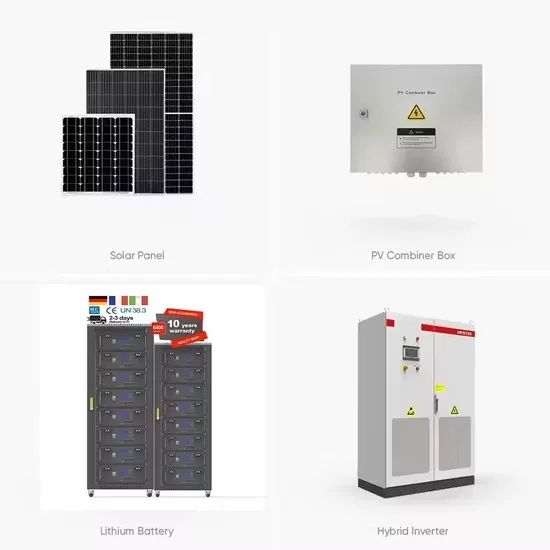

What are auxiliary systems?

Auxiliary systems are facilities that support the operation and maintenance of the substation and enable some wider wind farm maintenance activities. About £3.4 million for a 450 MW floating offshore wind farm.

What is a nacelle in a wind turbine?

The nacelle is the housing or enclosure that contains the main components of the wind turbine, such as the rotor, generator, and control systems. What role does the control system play in a wind turbine?

What are the components of a wind turbine?

The main components of a wind turbine include the rotor, generator, tower, nacelle, and control system. What is the function of the rotor in a wind turbine? The rotor, also known as the blades or propellers, captures the kinetic energy of the wind and converts it into rotational motion. What does the generator do in a wind turbine?

Why do wind turbines need advanced control systems?

They ensure that the turbines operate at optimal conditions and help detect issues before they result in significant downtime. Advanced control systems can also adjust turbine activities in response to changes in wind speed and direction, ensuring maximum efficiency. JMS Energy’s Edge:

Why is electrical equipment needed for a wind turbine?

Electrical Equipment: Why is it necessary? The energy harnessed by a wind turbine needs to be efficiently transported and integrated into the grid. This requires a range of electrical equipment including transformers, power cables, switchgear, and substations.

Guess what you want to know

-

Mobile base station equipment power wind power generation

Mobile base station equipment power wind power generation

-

Rooftop vertical axis wind power generation system

Rooftop vertical axis wind power generation system

-

Direct-in wind power generation system

Direct-in wind power generation system

-

Base station wind power supply equipment model

Base station wind power supply equipment model

-

Togo communication base station wind power generation

Togo communication base station wind power generation

-

Communication base station wind power equipment manufacturer

Communication base station wind power equipment manufacturer

-

Detailed explanation of 5G communication base station wind power equipment

Detailed explanation of 5G communication base station wind power equipment

-

Power generation equipment container house enterprise

Power generation equipment container house enterprise

-

Wind Power Generation and Mesoscale Systems

Wind Power Generation and Mesoscale Systems

-

Communication base station wind power generation model

Communication base station wind power generation model

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.