Design optimization and site matching of direct-drive permanent

The optimum design models of direct-drive PM wind generation system are developed with an improved genetic algorithm, and a 500-kW direct-drive PM generator for the

Get a quote

The Future of Wind Turbines: Comparing Direct Drive

To eliminate gearbox failure and transmission losses, manufacturers have developed wind turbines without gearboxes. This type of wind turbine

Get a quote

Review of Generator Systems for Direct-Drive Wind Turbines

In order to identify suitable generator concepts for direct-drive wind turbines, the comparisons of different generator systems in literature are discussed with the criteria based on the energy

Get a quote

Direct Drive Wind Turbine vs. Geared Drive Wind Turbine

Considering the energy yield and reliability, the direct drive generator systems seem to be more powerful compared to geared drive systems, especially for offshore. The permanent magnet

Get a quote

Design Aspects of Direct Drive Permanent Magnet Machines

In the recent studies, it has shown that the AFMs are very attractive and cost-effective alternatives for Radial Flux machines (RFMs) especially for applications such as small wind power system,

Get a quote

Direct Drive Permanent Magnet Synchronous Generator:

In this section, a DD-SPMSG with 64 poles pairs, 660 kW rated power and 46.875 rpm rated mechanical speed is analytically designed. The principal dimensions of the generator are

Get a quote

Modeling and Control of a Standalone PMSG Wind Generation System

This chapter presents a control strategy for a standalone wind generation system based on a permanent magnet synchronous generator (PMSG), in order to extract the

Get a quote

The Future of Wind Turbines: Comparing Direct Drive and Gearbox

To eliminate gearbox failure and transmission losses, manufacturers have developed wind turbines without gearboxes. This type of wind turbine was introduced in 1991,

Get a quote

Modelling and Simulation of Direct Drive Permanent Magnet Wind Power

The widely used grid-connected wind power generation system is mostly adopted asynchronous generator, which has low efficiency. Therefore, A direct-wind power generation system based

Get a quote

Simulation study on direct-drive wind power system

The main components of direct-drive wind power systems include wind turbines, permanent magnet synchronous generator (PMSG), dual PWM

Get a quote

An engineering design of a 2MW direct-drive permanent-magnet wind-power

With rapid development of the power semiconductor devices, direct-drive permanent magnet synchronous generator (PMSG) has shown the significant advantages for its high efficiency,

Get a quote

Direct Drive Wind Turbine vs. Geared Drive Wind

Considering the energy yield and reliability, the direct drive generator systems seem to be more powerful compared to geared drive systems, especially for

Get a quote

(PDF) Cooling Techniques in Direct-Drive Generators

Abstract and Figures Direct-drive generators are an attractive candidate for wind power application since they do not need a gearbox, thus

Get a quote

Control of Parallel Multiple Converters for Direct-Drive Permanent

This paper proposes control strategies for megawatt-level direct-drive wind generation systems based on permanent magnet synchronous generators. In the paper, a

Get a quote

Design Optimization of a Direct-Drive Wind Generator with a

Abstract—This paper presents a large-scale multi-objective design optimization for a direct-drive wind turbine generator concept that is based upon an experimentally validated compu-tational

Get a quote

Modelling and Simulation of Direct Drive Permanent Magnet Wind

The widely used grid-connected wind power generation system is mostly adopted asynchronous generator, which has low efficiency. Therefore, A direct-wind power generation system based

Get a quote

IEEE Paper Template in A4 (V1)

Direct Drive System: Unlike geared systems, direct drive turbines eliminate the gearbox and connect the generator directly to the rotor. This minimizes mechanical losses and increases

Get a quote

Multiple-time-scales parameters stability domain construction for

To investigate the stable operation mechanism and control parameters of the interaction system under multiple-time-scales, a simplified interaction model of direct-drive

Get a quote

Simulation study on direct-drive wind power system

The main components of direct-drive wind power systems include wind turbines, permanent magnet synchronous generator (PMSG), dual PWM AC/DC converters, DC bus

Get a quote

Machine-side Harmonic Suppression Strategy for Direct

1Abstract—Wind power generation system with five-phase PMSG contains a large amount of third harmonic in the stator phase current of the machine side due to the dead-time effect of the

Get a quote

How Do Wind Turbines Work?

The terms "wind energy" and "wind power" both describe the process by which the wind is used to generate mechanical power or electricity. This mechanical

Get a quote

Comprehensive overview of grid interfaced wind energy generation systems

The knowledge of actual time-varying availability of wind speed is essential for accurately determining electricity generation in grid connected wind power plants [7]. High

Get a quote

Modern electric machines and drives for wind power

Abstract With ever-increasing concerns on energy crisis and environmental protection, there is a fast-growing interest in wind power

Get a quote

Modeling of Direct-Drive Permanent Magnet Synchronous Wind Power

The dynamics of wind power generation cannot be neglected in the modern power system and could have a great impact on the system dynamics, even raising the risk of a

Get a quote

Analysis of Grid-Connected Wind Power Generation Systems at

Modeling and simulation of grid-connected wind generation systems using permanent magnet synchronous generator (PMSG) are presented in this paper. A three-phase

Get a quote

Wind Turbine Generator Technologies

Initially, wind energy started to gain popularity in electricity generation to charge batteries [17] in remote power systems, residential scale power systems, isolated or island

Get a quote

A review on the inclusion of wind generation in power system

The correlation between wind generators in a wind farm has also been discussed. For the successful operation of power system with wind, it is mandatory to have power system

Get a quote

Multiple-time-scales parameters stability domain construction for

On this basis, the multi-time-scales stable operating characteristics of the interaction system, both in series and parallel configurations, are thoroughly analyzed. The stable

Get a quote

Modeling of Direct-Drive Permanent Magnet Synchronous Wind

The dynamics of wind power generation cannot be neglected in the modern power system and could have a great impact on the system dynamics, even raising the risk of a

Get a quote

6 FAQs about [Direct-in wind power generation system]

What is a direct-drive generator for a wind turbine?

In the direct-drive generator for wind turbine, the rotor is directly connected to the rotor hub. Direct-drive generators operate at the same speed as the turbine's blades and must therefore be much bigger.

How does a direct drive wind turbine work?

A direct-drive wind turbine’s generator speed is equivalent to the rotor speed, because the rotor is connected directly to the generator. As the rotational generator speed is low, designers placed several magnetic poles in the generator to achieve the appropriate high output frequency.

What is the structure of a direct drive wind generator?

ical structures of direct-drive wind generators 3.1.1. Conventional StructureTraditionally the rotor of generator is connected to a shaft mounted on bearings that enable the rotation in the stator as shown in Fig. 23 The structure of Fig. 24(a) is widely used on the wi d turbine market by Enercon GmbH, whose world market share was abo

What is the topology of direct-drive wind power generation systems?

The topology of the direct-drive wind power generation systems connected to the weak power grid is illustrated in Fig. 1, including the wind turbine, Permanent Magnet Synchronous Generator (PMSG), machine-side converter (MSC), DC capacitor, grid-side converter (GSC), filter inductors, and the AC power grid.

Are wind turbines geared or direct drive?

According to the drivetrain condition in a wind generator system, wind turbines can be classified as either direct drive or geared drive groups.

What are the advantages of direct-drive wind turbines?

1. The costs for the offshore support structure for direct-drive wind turbines is lower due to its lighter weight. 2. Direct-drive has more potential for further improvement. Experts argue the gearbox wind turbine is almost at its maximum efficiency point, while the direct-drive turbines have more possibilities for improvement.

Guess what you want to know

-

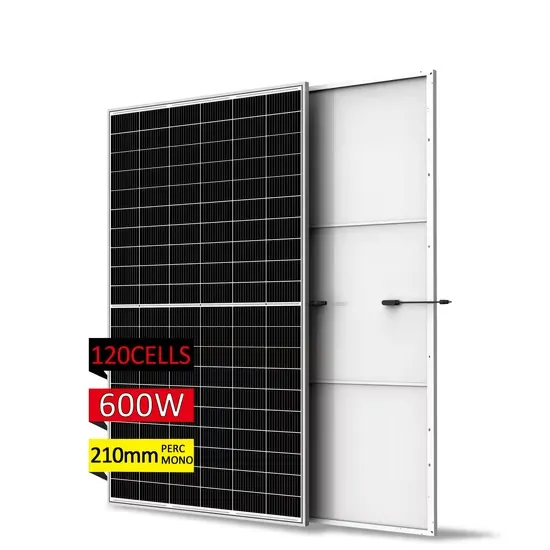

Home solar integrated wind power generation

Home solar integrated wind power generation

-

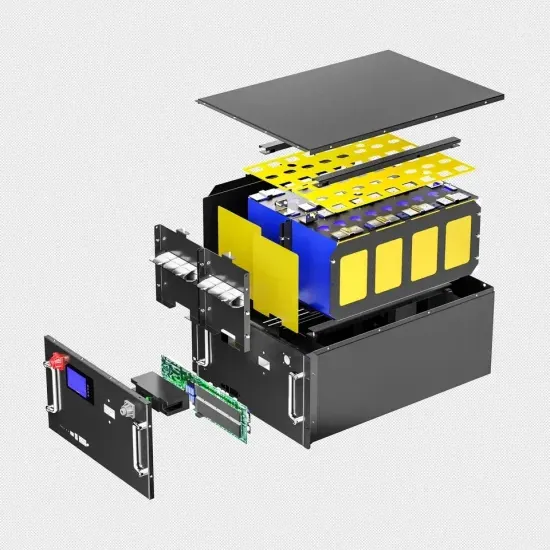

Wind power generation energy storage complete set

Wind power generation energy storage complete set

-

What does wind power and photovoltaic power generation include in Swedish communication base stations

What does wind power and photovoltaic power generation include in Swedish communication base stations

-

Forestry photovoltaic and wind power generation systems

Forestry photovoltaic and wind power generation systems

-

Base station power supply centralized wind power generation network

Base station power supply centralized wind power generation network

-

Central African Republic grid-connected wind power generation system

Central African Republic grid-connected wind power generation system

-

Brazil Mobile Communication Wind Power Base Station Photovoltaic Power Generation System

Brazil Mobile Communication Wind Power Base Station Photovoltaic Power Generation System

-

Wind and solar power generation for photovoltaic power stations

Wind and solar power generation for photovoltaic power stations

-

Wind power generation energy storage 100 degrees

Wind power generation energy storage 100 degrees

-

Niue Off-Grid Small Wind Power Generation System

Niue Off-Grid Small Wind Power Generation System

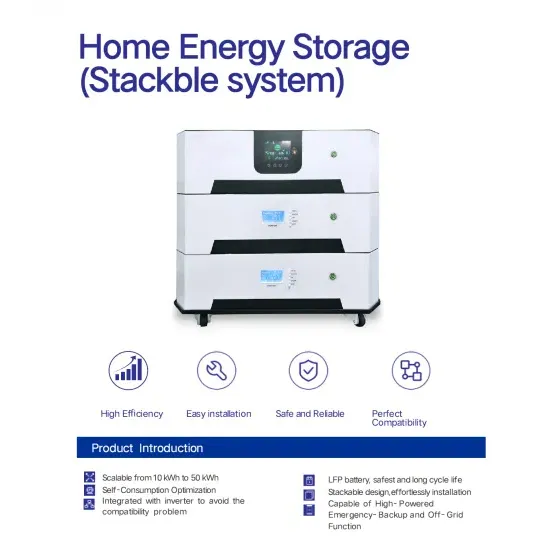

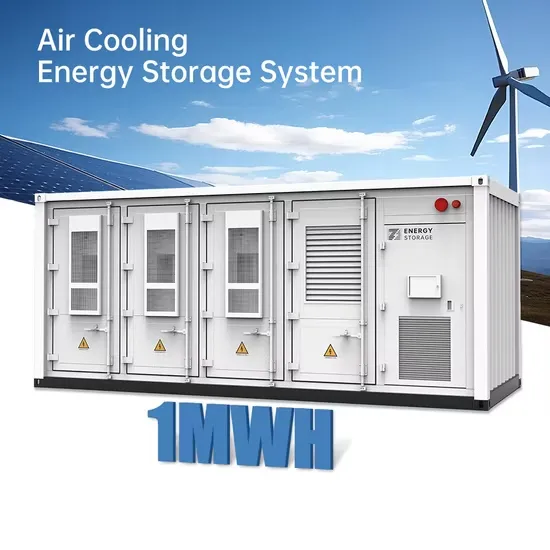

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.