On-site quality inspections for energy storage components

Sinovoltaics performs independent quality inspections on-site at the Battery Energy Storage factories in Asia, assuring the workmanship quality, constructional design conformity,

Get a quote

What aspects does the inspection of industrial and commercial

Below, I share practical testing insights for the five core subsystems (battery, BMS, PCS, thermal management, EMS) and three - tiered inspection framework (daily checks,

Get a quote

Why Container Energy Storage Quality Inspection is Your New

Next time you see a container energy storage system, remember: it''s not just a metal box. It''s a carefully orchestrated symphony of technology, quality control, and enough potential energy to

Get a quote

Comprehensive Guide to Inspecting Fully Integrated BESS

To ensure the reliability, efficiency, and safety of these systems, regular inspections are essential. This article will guide you through the key aspects of inspecting a

Get a quote

IR N-4: Modular Battery Energy Storage Systems: 2022 CBC

The following regulations address Fire and Life Safety requirements: California Fire Code (CFC), Section 1207, Electrical Energy Storage Systems; California Electrical Code (CEC), Article

Get a quote

Comprehensive Guide to Inspecting Fully Integrated

To ensure the reliability, efficiency, and safety of these systems, regular inspections are essential. This article will guide you through the key

Get a quote

Energy Storage Solutions Inspection Checklist and

Ensure top-notch quality with QCADVISOR''s Energy Storage Solutions inspection checklist & template. Simplify quality control and streamline your inspections

Get a quote

Battery Energy Storage Systems (Bess)

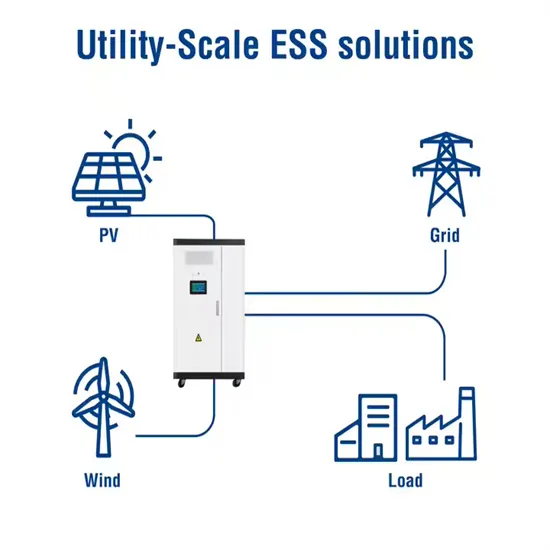

Dawnice battery energy storage systemseamlessly combine high power density, digital connectivity, multilevel safety, black start capability, scalability, ultra-fast

Get a quote

Containerized Energy Storage System: How it Works

A Containerized Energy-Storage System, or CESS, is an innovative energy storage solution packaged within a modular, transportable container. It

Get a quote

Quality Control and Testing for Battery Energy Storage Systems

Our engineers confirm the final products are safely loaded without damage, secured, sealed, and accurately recorded on the Bill of Lading. CEA''s container loading monitoring reports include

Get a quote

Container energy storage quality inspection

Sinovoltaics advice: we suggest having the logistics company come inspect your Battery Energy Storage System at the end of manufacturing,in order for them to get accustomed to the BESS

Get a quote

What aspects does the inspection of industrial and commercial energy

Below, I share practical testing insights for the five core subsystems (battery, BMS, PCS, thermal management, EMS) and three - tiered inspection framework (daily checks,

Get a quote

BATTERY ENERGY STORAGE SYSTEMS

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this

Get a quote

Shipping & Cargo Containers Inspection Checklist and Template

Shipping and cargo containers are essential for transporting goods across the globe. They come in various subcategories, including dry containers, refrigerated containers, and tank

Get a quote

Energy Storage Solutions Inspection Checklist and Template

Ensure top-notch quality with QCADVISOR''s Energy Storage Solutions inspection checklist & template. Simplify quality control and streamline your inspections today!

Get a quote

Energy Storage Containers: The Unsung Heroes of Modern

Why Energy Storage Containers Are Stealing the Spotlight It''s 3 AM, and your factory''s assembly line suddenly loses power. Cue panic, right? Enter energy storage

Get a quote

What tests should be done on energy storage containers?

The outlined evaluations for energy storage containers—performance tests, safety assessments, environmental impact evaluations, and maintenance inspections—are

Get a quote

BESS Acceptance Testing (FAT / SAT)

Utilize BESSential, our comprehensive quality control service for battery energy storage systems (BESS) and benefit from our partnership with Sinovoltaics.

Get a quote

Battery FAT vs SAT Testing Explained | Factory vs Site

Energy storage battery systems require similar "pre-purchase inspection" and "post-delivery verification"—this is where FAT (Factory Acceptance Testing) and SAT (Site Acceptance

Get a quote

How to Comply with Shipping Container Building

Learn how to comply with shipping container building codes, including zoning laws, permits, structural integrity, and fire safety. Ensure your container home

Get a quote

Blogs, News, Events

A Factory Acceptance Test (FAT) is a critical procedure to verify the functionality, safety, and reliability of equipment before it''s deployed. In the case of the Pressurized

Get a quote

Energy storage battery container factory inspection

When it comes to ensuring the quality,performance,and reliability of energy storage battery systems,two critical phases stand out: Factory Acceptance Testing (FAT) and Site Acceptance

Get a quote

Pfannenberg 1000W (3412BTU) Energy-Efficient Mini AC

Pfannenberg 1000w (3412btu) Energy-efficient Mini Ac - Ce-certified Factory-direct For Industrial Enclosure Cooling - Buy High - Powered Outdoor Telecom Cabinet Ac For Power Substations

Get a quote

Battery FAT vs SAT Testing Explained | Factory vs

Energy storage battery systems require similar "pre-purchase inspection" and "post-delivery verification"—this is where FAT (Factory Acceptance Testing)

Get a quote

6 FAQs about [Factory inspection of energy storage containers]

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

When should a battery energy storage system be inspected?

Sinovoltaics advice: we suggest having the logistics company come inspect your Battery Energy Storage System at the end of manufacturing, in order for them to get accustomed to the BESS design and anticipate potential roadblocks that could delay the shipping procedure of the Energy Storage System.

What should be included in a contract for an energy storage system?

Several points to include when building the contract of an Energy Storage System: • Description of components with critical tech- nical parameters:power output of the PCS, ca- pacity of the battery etc. • Quality standards:list the standards followed by the PCS, by the Battery pack, the battery cell di- rectly in the contract.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

When does an energy storage project start?

“The operations and maintenance phase of an en- ergy storage project begins when the system has been successfully commissioned and the owner has obtained approval to operate the system.

Does container manufacturing take a lot of space?

Container manufacturing can take (a lot of) space. If your project requires a 40ft container, your contain- er manufacturing will probably take place outdoors. During that step, several points need to be looked at: • Manufacturing environment: no clean room re- quired here, but is there any risk of electrocution following a heavy rain?

Guess what you want to know

-

Factory Operation Solution for Energy Storage Containers

Factory Operation Solution for Energy Storage Containers

-

Battery Energy Storage Factory Inspection

Battery Energy Storage Factory Inspection

-

Mauritius Battery Energy Storage Box Source Factory

Mauritius Battery Energy Storage Box Source Factory

-

What is the price of distributed energy storage cabinet factory in Guinea-Bissau

What is the price of distributed energy storage cabinet factory in Guinea-Bissau

-

Oman photovoltaic energy storage cabinet battery factory system

Oman photovoltaic energy storage cabinet battery factory system

-

Myanmar energy storage container power station factory is running

Myanmar energy storage container power station factory is running

-

Togo Photovoltaic Energy Storage Cabinet Battery Factory Company

Togo Photovoltaic Energy Storage Cabinet Battery Factory Company

-

Factory Energy Storage Equipment Price Trends

Factory Energy Storage Equipment Price Trends

-

What are the structural characteristics of energy storage containers

What are the structural characteristics of energy storage containers

-

Dominica Energy Storage Lithium Battery Component Factory

Dominica Energy Storage Lithium Battery Component Factory

Industrial & Commercial Energy Storage Market Growth

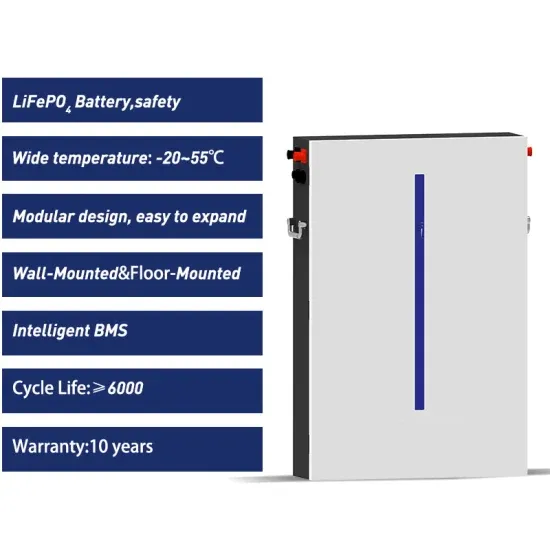

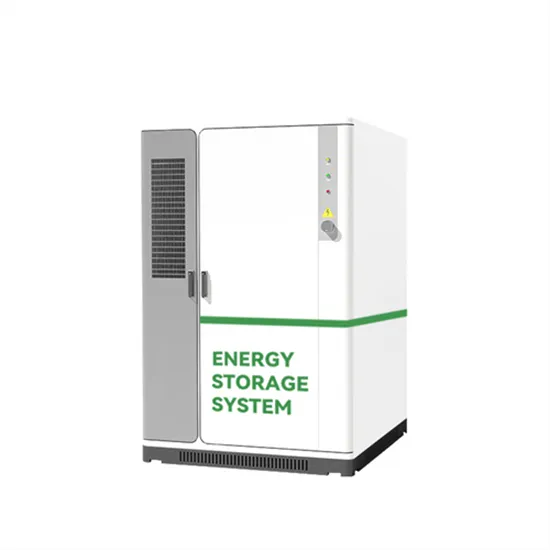

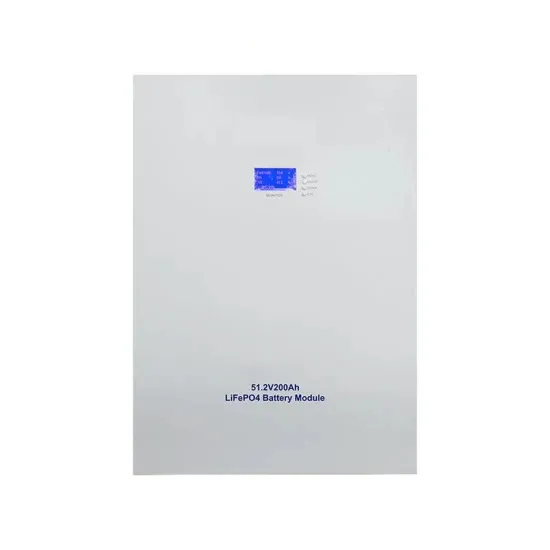

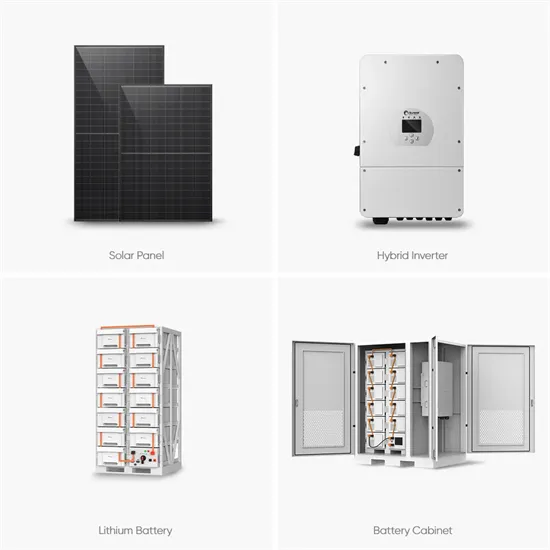

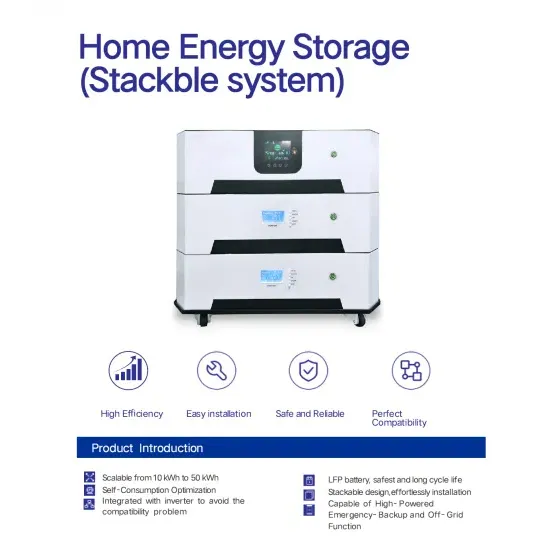

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.