BATTERY FAT and SAT Major Testing Components & Procedures

When it comes to ensuring the quality, performance, and reliability of energy storage battery systems, two critical phases stand out: Factory Acceptance Testing (FAT) and

Get a quote

Energy Storage Inspection 2025: RCT Power, Fronius, BYD and

The University of Applied Sciences (HTW) Berlin has published its annual Energy Storage Inspection. In addition to the efficiency of home storage systems in the 5 kW and 10 kW

Get a quote

Energy Storage System Testing and Certification

Safety testing and certification for energy storage systems (ESS) Large batteries present unique safety considerations because they contain high levels of

Get a quote

Energy Storage Quality Control | Applus+ USA

Enertis Applus+''s highly specialized BESS quality control and quality assurance services cover the planning and manufacturing phases of battery energy storage systems projects.

Get a quote

BESS Acceptance Testing (FAT / SAT)

Learn all about factory & site acceptance testing in our BESSential white paper! In the evolving energy storage landscape, ensuring BESS reliability and safety

Get a quote

BESS Factory Acceptance Testing Procurement Checklist

Factory Acceptance Testing (FAT) is a critical step in the Battery Energy Storage System (BESS) procurement process, ensuring that the system meets technical specifications, safety

Get a quote

Battery Energy Storage System (BESS)

Battery Energy Storage System (BESS) To the extent that this report is based on information supplied by other parties, Hatch accepts no liability for any loss or damage suffered, whether

Get a quote

Container energy storage system inspection

The Battery energy storage system (BESS) container are based on a modular design. They can be configured to match the required power and capacity requirements of client''''s application.

Get a quote

HANDBOOK FOR ENERGY STORAGE SYSTEMS

ABBREVIATIONS AND ACRONYMS Alternating Current Battery Energy Storage Systems Battery Management System Battery Thermal Management System Depth of Discharge Direct

Get a quote

Virginia Streamlines Battery Storage Permitting

In December, the SCC issued final rules for the implementation of the VCEA''s energy storage targets. The rules set interim targets for Dominion Energy and Appalachian Power to achieve

Get a quote

Energy Storage Solutions Inspection Checklist and

Energy storage solutions are essential for storing and releasing energy efficiently. This product category includes batteries, capacitors, and flywheels. Quality

Get a quote

Battery Energy Storage Systems: Main Considerations for Safe

This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

Get a quote

Energy Storage Solutions Inspection Checklist and Template

Check for any visible damage or cracks on the exterior of the product. Inspect the product for any loose or missing parts. Ensure that all buttons, switches, and controls are functioning properly.

Get a quote

Acceptance Specifications for Battery Energy Storage Stations

The Federal Energy Management Program (FEMP) provides a customizable template for federal government agencies seeking to procure lithium-ion battery energy storage systems (BESS).

Get a quote

Quality Control and Testing for Battery Energy Storage Systems

CEA''s factory audits utilize our time-tested 400+ point checklist to provide industry-leading insights into the production processes and quality standards of any storage manufacturer''s

Get a quote

Battery FAT vs SAT Testing Explained | Factory vs Site

Energy storage battery systems require similar "pre-purchase inspection" and "post-delivery verification"—this is where FAT (Factory Acceptance Testing) and SAT (Site Acceptance

Get a quote

Energy Storage Solutions Inspection Checklist and

Check for any visible damage or cracks on the exterior of the product. Inspect the product for any loose or missing parts. Ensure that all buttons, switches, and

Get a quote

Battery FAT vs SAT Testing Explained | Factory vs

Energy storage battery systems require similar "pre-purchase inspection" and "post-delivery verification"—this is where FAT (Factory Acceptance Testing)

Get a quote

Battery Energy Storage System Inspection and Testing

These Guidelines provide information on the Inspection and Testing procedures to be carried out by the eligible consumer at the end of the construction of a BESS System, in order to connect

Get a quote

The BESS System: Construction, Commissioning, and

A comprehensive guide on the construction, commissioning, and operation & maintenance of industrial and commercial energy storage systems.

Get a quote

BESS Acceptance Testing (FAT / SAT)

Learn all about factory & site acceptance testing in our BESSential white paper! In the evolving energy storage landscape, ensuring BESS reliability and safety before commissioning is

Get a quote

BATTERY INSPECTION CHECKLIST

Note: Battery should be Replaced if ~ Point 2,4 & 7: Badly damage ~ Point 16: < 6,5 VDC or < 300A Battery should be Recharged if ~ All Visual Inspection OK ~ Point 16 in Range: 6,5 VDC

Get a quote

Battery energy storage systems | BESS

Battery energy storage (BESS) offer highly efficient and cost-effective energy storage solutions. BESS can be used to balance the electric grid, provide

Get a quote

Modernizing Traditional BESS Factory Acceptance Testing

EXECUTIVE SUMMARY This white paper outlines a transformative approach to quality assurance for Battery Energy Storage Systems (BESS). As the demand for reliable and

Get a quote

Microsoft Word

The inspector will also confirm the energy storage system equipment is permanently installed and is of the same make, model, capacity, and configuration that is 5 A factory test is a test

Get a quote

6 FAQs about [Battery Energy Storage Factory Inspection]

What are the two phases of energy storage battery testing?

When it comes to ensuring the quality, performance, and reliability of energy storage battery systems, two critical phases stand out: Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT).

What is a battery energy storage system?

Battery energy storage systems (BESS) stabilize the electrical grid, ensuring a steady flow of power to homes and businesses regardless of fluctuations from varied energy sources or other disruptions. However, fires at some BESS installations have caused concern in communities considering BESS as a method to support their grids.

What is sat for energy storage battery systems?

SAT for energy storage battery systems aims to: Verify Installation: Ensure the system is installed according to specifications and standards. Perform Integration Testing: Confirm integration with the site’s electrical and control systems. Validate Performance: Ensure the system operates as expected in its operational environment.

What is a battery energy storage system (BESS)?

The most dominant technology being deployed in recent years across the electric grid are battery energy storage systems (BESSs), which interconnect to both distribution and transmission systems.

What are the primary objectives of fat for energy storage battery systems?

The primary objectives of FAT for energy storage battery systems include: Verification of Design and Specifications: Ensuring the system meets the design specifications and performance requirements outlined in the contract. Functional Testing: Confirming that the system operates correctly under different conditions and scenarios.

What is fat for energy storage battery systems?

FAT for energy storage battery systems typically includes the following components: Visual Inspection: Checking for physical damages, proper labeling, and adherence to design specifications. Electrical Testing: Verifying electrical performance, including voltage, current, and capacity measurements.

Guess what you want to know

-

A lithium battery energy storage system factory in Bulgaria

A lithium battery energy storage system factory in Bulgaria

-

Super Energy Storage Battery Factory

Super Energy Storage Battery Factory

-

Energy storage battery container custom factory

Energy storage battery container custom factory

-

Albania lithium battery energy storage cabinet installation factory is running

Albania lithium battery energy storage cabinet installation factory is running

-

Togo Photovoltaic Energy Storage Cabinet Battery Factory Company

Togo Photovoltaic Energy Storage Cabinet Battery Factory Company

-

Energy storage cabinet battery factory base station and price

Energy storage cabinet battery factory base station and price

-

Marshall Islands Energy Storage Container Lithium Battery Factory

Marshall Islands Energy Storage Container Lithium Battery Factory

-

Huawei Sierra Leone Energy Storage Battery Factory

Huawei Sierra Leone Energy Storage Battery Factory

-

Peru Energy Storage Lithium Battery Station Cabinet Factory

Peru Energy Storage Lithium Battery Station Cabinet Factory

-

Lithium Battery Energy Storage Cabinet Factory

Lithium Battery Energy Storage Cabinet Factory

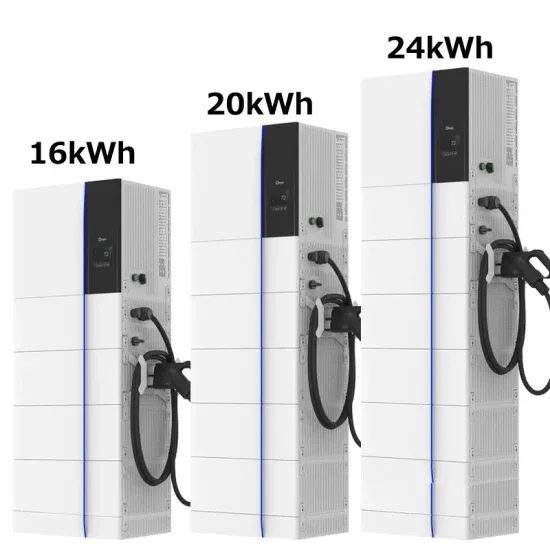

Industrial & Commercial Energy Storage Market Growth

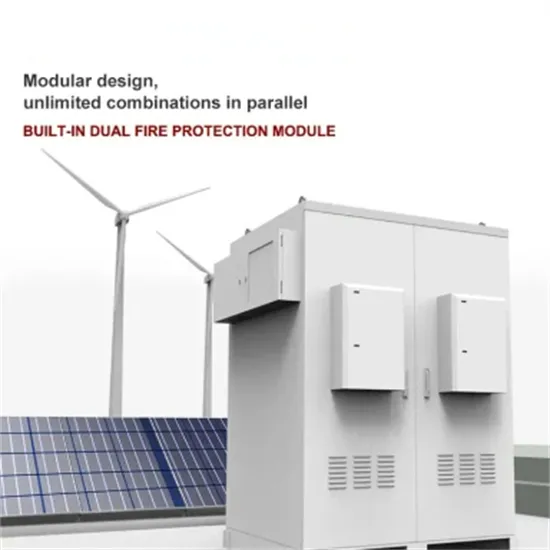

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.