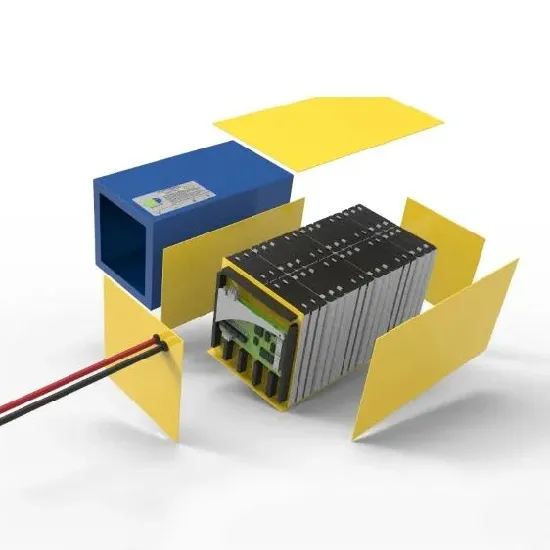

Battery Management System

Ensure the BMS is compatible with your specific type of battery (e.g., Li-ion, LiFePO4, NiMH). Each chemistry has unique voltage thresholds and operational parameters

Get a quote

Cell balancing, Capacity Matching vs Capacity Preservation

Cell balancing is a critical process in battery management systems, focusing on optimizing performance and longevity. Capacity matching aims to maximize energy output,

Get a quote

LiFePO4 BMS Selection Guide: Matching Your Pack''s Voltage, C

An essential component of every battery pack, a BMS is in charge of monitoring, balancing, and protecting cells from temperature and electrical hazards. In this post, we''ll

Get a quote

3. System design and BMS selection guide

All available BMS types for the lithium battery are based on either or both of these technologies. The BMS types and their functionality are briefly described in the next chapters.

Get a quote

How Do You Match a Battery to a BMS?

To effectively match a battery to a Battery Management System (BMS), it is essential to consider the battery''s voltage, capacity, and chemistry. A properly matched BMS

Get a quote

the way of matching battery pack to battery management system

Matching the battery with the BMS (Battery Management System) requires comprehensive consideration of multiple technical parameters, functional requirements and application

Get a quote

Understanding BMS in Lithium Batteries: Importance

Though a BMS adds to the initial cost of a battery system, it pays off in the long run by maximizing battery life, performance, and safety. Users

Get a quote

the way of matching battery pack to battery management system (bms

Matching the battery with the BMS (Battery Management System) requires comprehensive consideration of multiple technical parameters, functional requirements and application

Get a quote

Battery Cell Matching Importance

Implement the methodologies discussed—from 4-parameter matching to BMS integration—to unlock your battery system''s full potential. As battery technology advances,

Get a quote

Choosing the Perfect BMS: Unlock Your Battery''s Full Potential

This comprehensive guide will walk you through the essential factors to consider when choosing a BMS for these popular cell types, providing in-depth information for both beginners and

Get a quote

Battery Management System (BMS): Diagrams & IC Selection

Battery Management System (BMS) explained: key functions, block/circuit diagrams (PDF), LiFePO4 notes, 12V/24V/3S cases, and cross-brand IC choices with price

Get a quote

How to Choose a Compatible Replacement BMS for E

Learn how to choose a compatible replacement BMS for your e-bike battery, ensuring safety, optimal performance, and preventing issues like

Get a quote

Complete Battery Management System (BMS) Guide

Explore how the Battery Management System (BMS) protects and optimizes your electric bike battery. Learn detailed functions, maintenance

Get a quote

Does the BMS have to be connected to the inverter?

The battery parameters can be entered on the Solis and it will then be able to estimate the SOC. However a friend of mine who built his own battery has told me that there is

Get a quote

BMS and communication protocols-Residential

Battery Management System (BMS) is an electronic device that monitors and manages the battery by collecting and calculating parameters such as voltage,

Get a quote

Choosing the right BMS

The bms needs to protect the battery, so 100 amps would be the maximum you should use. If you really do pull 60 amps, then you''d pop the bms all the time if you use a 60

Get a quote

Choosing BMS for 21700 li ion batteries : r/ElectricalEngineering

These are what normally get used for custom li ion battery packs, they balance the cells and have some various protection features, you''ll most likely have to switch to 8s or 10s, 9s packs aren''t

Get a quote

BMS LiFePO4 Guide: Safety, Setup & Sizing

Clear, practical guide to BMS LiFePO4: safety features, wiring basics, setup steps, and sizing so your LiFePO4 battery runs longer and safer.

Get a quote

How to Choose the Best BMS for Your Battery Needs

To choose the best BMS, start by defining your battery type, voltage, current, and application requirements. Compare BMS features against these needs, prioritizing safety,

Get a quote

How does a BMS handle cell mismatch? | Wolfchip Electronics

- BMS designs vary based on application requirements. - Automotive EVs, grid-scale energy storage, and portable devices have different cell mismatch handling capabilities.

Get a quote

A Complete Guide to Resetting Your Car''s Battery Management

Everything You Need to Know About Resetting Your Car''s Battery Management System If you own an electric vehicle (EV) or a newer gas-powered car, your vehicle likely has

Get a quote

6 FAQs about [Battery BMS matching]

What is a battery management system (BMS)?

The functionality of a BMS extends to: Ensure the BMS is compatible with your specific type of battery (e.g., Li-ion, LiFePO4, NiMH). Each chemistry has unique voltage thresholds and operational parameters that the BMS must be able to manage. Centralized BMS: Suitable for smaller packs or where cost is a concern.

How does a battery communicate with a BMS?

The battery communicates these alarms to the BMS via its BMS cables. The BMS receives an alarm signal from a battery cell If the system contains multiple batteries, all battery BMS cables are connected in series (daisy chained). The first and the last BMS cable is connected to the BMS.

Why should I choose a high-quality battery management system (BMS)?

Higher-quality BMSs often provide better protection and longer lifespan. Note: Always verify compatibility and performance for your specific application. Selecting the appropriate BMS for 18650 and 21700 lithium-ion cell configurations is a critical step in designing safe and efficient battery systems.

How do I choose the right battery management system?

Selecting the right Battery Management System (BMS) involves understanding your battery’s needs and the specific features that a BMS can offer to meet those needs. By considering the factors outlined above, you can make an informed decision that enhances the performance and longevity of your battery systems.

How does a BMS charge a battery?

There are two ways the BMS can control loads and chargers: By sending an electrical or digital on/off signal to the charger or load. By physically connecting or disconnecting a load or a charge source from the battery. Either directly or by using a BatteryProtect or Cyrix Li-ion relay.

How does a BMS receive an alarm signal?

The BMS receives an alarm signal from a battery cell If the system contains multiple batteries, all battery BMS cables are connected in series (daisy chained). The first and the last BMS cable is connected to the BMS. The BMS receives an alarm signal from a cell in a multiple-battery setup The battery is equipped with 50 cm long BMS cables.

Guess what you want to know

-

Palestine BMS Battery Management Control System

Palestine BMS Battery Management Control System

-

Nicaragua lithium battery bms wholesale

Nicaragua lithium battery bms wholesale

-

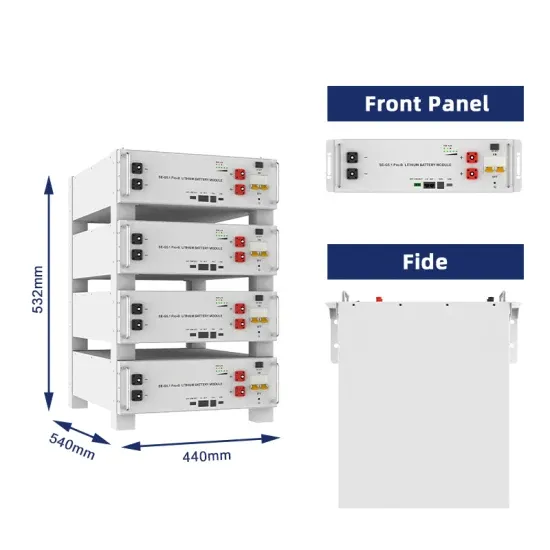

Bms battery management system products

Bms battery management system products

-

Bms battery replacement

Bms battery replacement

-

Greek lithium battery bms function

Greek lithium battery bms function

-

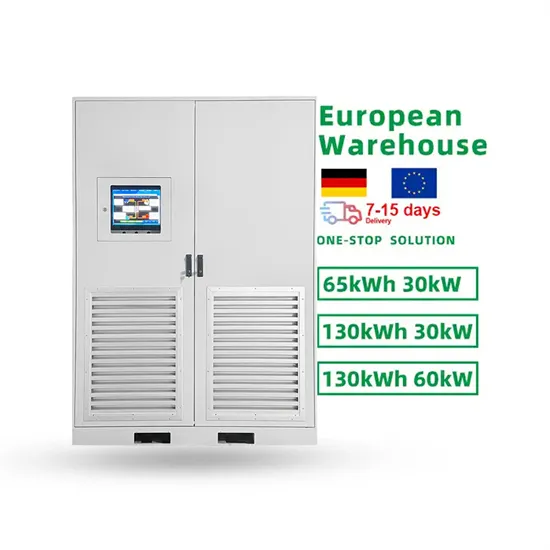

Türkiye outdoor battery cabinet BMS solution

Türkiye outdoor battery cabinet BMS solution

-

Maldives BMS lithium battery project

Maldives BMS lithium battery project

-

Sierra Leone professional lithium battery bms manufacturer

Sierra Leone professional lithium battery bms manufacturer

-

Solar storage battery matching

Solar storage battery matching

-

Russian BMS lithium battery

Russian BMS lithium battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.