What are the solar powered factories? | NenPower

Solar-powered factories utilize solar energy as a primary power source, offering a sustainable alternative to traditional manufacturing facilities

Get a quote

Lenovo Boosts Sustainability Efforts at European

Adding increased solar generation capacity has been an ongoing project and it is an exciting moment to now have the ability to run our Global

Get a quote

How to Build an Energy-Ready Factory with Solar

Don''t treat solar as an afterthought. Modern factories need more than walls and machines — they need integrated energy systems from day one.

Get a quote

Future of Solar Energy in Factories: Embracing Sustainability

Discover the future of solar energy in factories, embracing sustainability and reducing carbon footprint through renewable energy solutions for industrial production.

Get a quote

Powering Manufacturing Plants with Solar: Engineering the

Discover how engineering innovation powers manufacturing with solar energy, reducing costs, boosting efficiency, and leading sustainability efforts.

Get a quote

What if I''m generating energy onsite in my office or factory?

Onsite energy generation brings complexity when it comes to accounting for your greenhouse gas (GHG) emissions. Here''s a breakdown of how to handle scope emissions in this scenario:

Get a quote

How Businesses Are Using On-Site Power to Lower Costs

Discover how large energy users are turning to on-site power generation to offset rising capacity costs, improve reliability, and meet green goals.

Get a quote

On-Site Solar Energy Company | Best Solar Installation Services

Choose India''s best solar energy company for your firm''s energy transition goals. We offer rooftop solar, ground-mount and solar carport solutions.

Get a quote

So I''ve heard of factories installing solar on their roofs... are there

Breweries (I''ve been working in one now for a couple of years) are typically interested in green and lower cost energy sources and and therefore solar is very common. We have nearly 1.5

Get a quote

Rooftop solar energy systems for onsite consumption in Vietnam

The demand for onsite energy consumption from rooftop solar energy projects have recently increased in Vietnam in general and in industrial zones or large factories/buildings of

Get a quote

Renewable Power for Production: Integrating Solar and Wind in

By installing rooftop or ground-mounted solar arrays, manufacturers can generate clean, on-site power to fuel their production processes. These solar installations can be

Get a quote

Powering Manufacturing Plants with Solar:

Discover how engineering innovation powers manufacturing with solar energy, reducing costs, boosting efficiency, and leading sustainability efforts.

Get a quote

Renewable Energy in Production: A New Perspective for

Explore how renewable energy is transforming manufacturing processes. Gain in-depth insights into the benefits, challenges, and strategic approaches manufacturers can take

Get a quote

How to Build an Energy-Ready Factory with Solar Integration?

Don''t treat solar as an afterthought. Modern factories need more than walls and machines — they need integrated energy systems from day one.

Get a quote

How to Start a Solar Panel Manufacturing Plant:

As the world shifts toward cleaner energy sources, understanding the nuances of this manufacturing process is more crucial than ever. The solar energy

Get a quote

Renewable Power for Production: Integrating Solar and Wind in Factory

By installing rooftop or ground-mounted solar arrays, manufacturers can generate clean, on-site power to fuel their production processes. These solar installations can be

Get a quote

Solar-Powered Factories: How Sustainable Production Is

As more companies push to reduce their carbon footprints, solar-powered factories are becoming important in sustainable manufacturing. These factories use advanced solar

Get a quote

Solar Energy

Transform your future with industry-leading solar training from SEI. Online courses, hands-on workshops, and professional certificate programs for clean energy careers since 1991.

Get a quote

Solar Power for Factories | Solaric Corporation

Discover the benefits of solar power for factories in the Philippines. Cut energy costs, boost efficiency, and support a greener future with Solaric.

Get a quote

The Ultimate Guide to Commercial Solar Power System for

Learn how a well-designed commercial solar power system for factories can save costs, enhance energy efficiency, and support sustainability. Explore installation, maintenance,

Get a quote

How to use solar energy in factories | NenPower

Solar energy integration in factories epitomizes a pivotal revolution toward sustainable industrial operations. By strategically adopting solar technology, factories benefit

Get a quote

Case Studies – On-Site Energy

September 7, 2023 On-site generation despite grid moratorium on connections Sector: Manufacturing Technology: Off-grid solar PV and Combined Heat + Power The

Get a quote

Solar Panel For Ice Factory Sustainable Energy #1

Solar panel for ice factory to produce energy on-site, reducing reliance on external power sources. This energy independence protects against fluctuating electricity prices.

Get a quote

Renewable Energy in Production: A New Perspective

Explore how renewable energy is transforming manufacturing processes. Gain in-depth insights into the benefits, challenges, and strategic

Get a quote

What are the solar powered factories? | NenPower

Solar-powered factories utilize solar energy as a primary power source, offering a sustainable alternative to traditional manufacturing facilities that typically depend on fossil fuels.

Get a quote

How can solar energy help factories to grow?

In an era where sustainability and efficiency are paramount, factories are increasingly turning to solar energy. This renewable energy source offers not only

Get a quote

6 FAQs about [Solar on-site energy source factory]

Can factories use solar power?

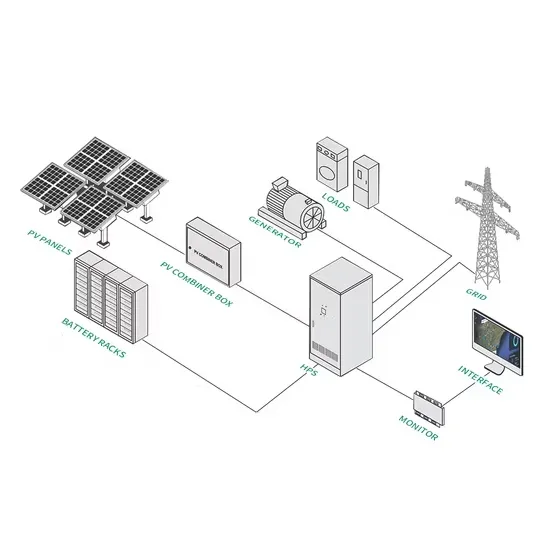

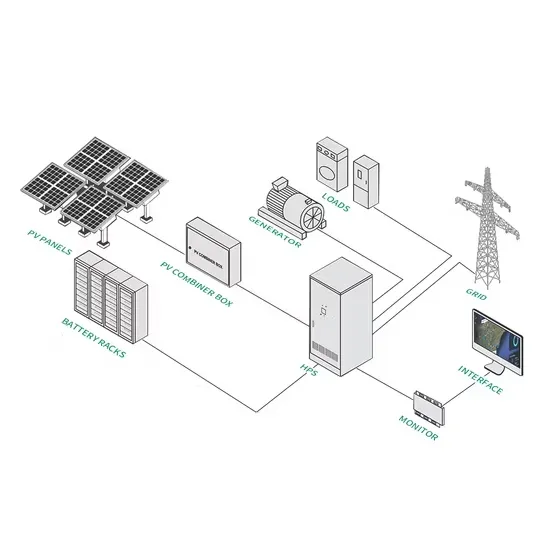

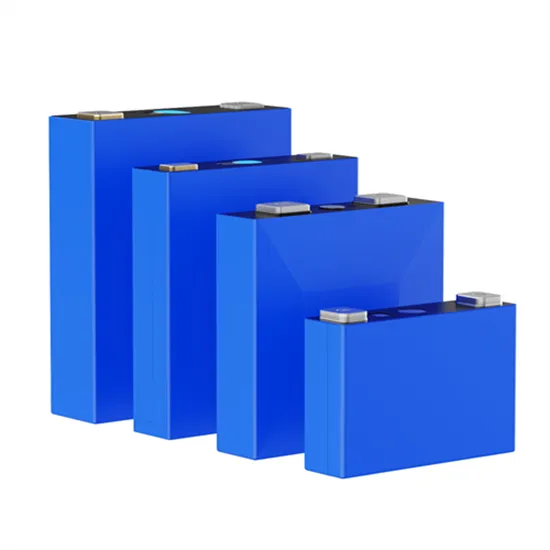

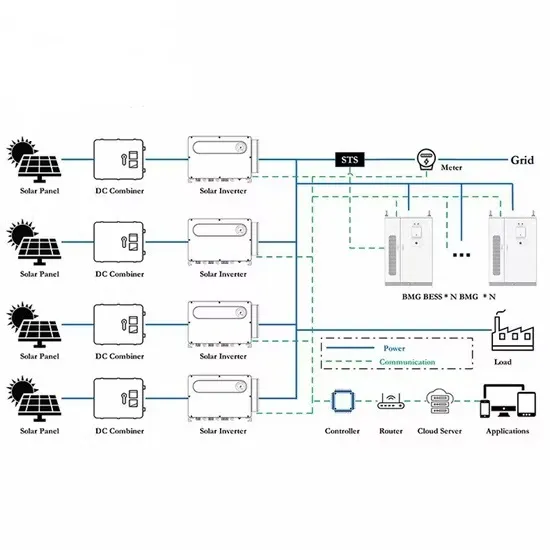

Additionally, some factories are pairing solar PV with energy storage systems, using batteries to store excess solar power for use during periods of high demand or low generation. While solar has gained significant traction, wind power is also emerging as a viable renewable energy source for factories.

What is a solar panel manufacturing plant?

Solar panel manufacturing plant produces renewable energy components. In the manufacturing world, renewable energy refers to integrating sustainable energy sources such as solar power, wind energy, biomass, and hydropower into production processes. These sources not only replenish naturally but also offer a cleaner alternative to fossil fuels.

Why is solar power a big part of factories?

Solar power is now a big part of factories, saving them money and helping the planet. Not just factories, but stores, hospitals, and schools are also getting energy from the sun. Many industries, which use a lot of energy, are stepping up to use solar power. They’re not just placing solar panels on roofs.

What is the future of solar energy in factories?

Discover the future of solar energy in factories, embracing sustainability and reducing carbon footprint through renewable energy solutions for industrial production. The International Energy Agency (IEA) says the global solar capacity will grow a lot. It will go up by more than 600 gigawatts in the next five years.

What makes a solar-powered manufacturing facility a good investment?

Solar-powered manufacturing facilities reflect a commitment to innovation and environmental stewardship, values increasingly important to consumers and stakeholders. Through engineering excellence, companies can demonstrate their dedication to renewable energy and sustainability.

Why do factories need solar & wind energy?

By diversifying their generation mix, factories can mitigate the inherent intermittency of individual renewable sources and ensure a more consistent power supply. The complementary nature of solar and wind energy makes them an ideal pairing for factory applications.

Guess what you want to know

-

Which solar panel on-site energy source is better

Which solar panel on-site energy source is better

-

Solar field energy source factory price

Solar field energy source factory price

-

Solar On-site Energy Outdoor New Product Recommendations

Solar On-site Energy Outdoor New Product Recommendations

-

Simple Solar PV On-site Energy

Simple Solar PV On-site Energy

-

Solar power generation on-site energy installation

Solar power generation on-site energy installation

-

Onsite energy source changed to solar panels

Onsite energy source changed to solar panels

-

Installation of solar on-site energy projects

Installation of solar on-site energy projects

-

Solar photovoltaic on-site energy storage battery self-operation

Solar photovoltaic on-site energy storage battery self-operation

-

Benin Solar Energy Storage Power Supply Factory

Benin Solar Energy Storage Power Supply Factory

-

Solar panels on-site energy storage outdoors

Solar panels on-site energy storage outdoors

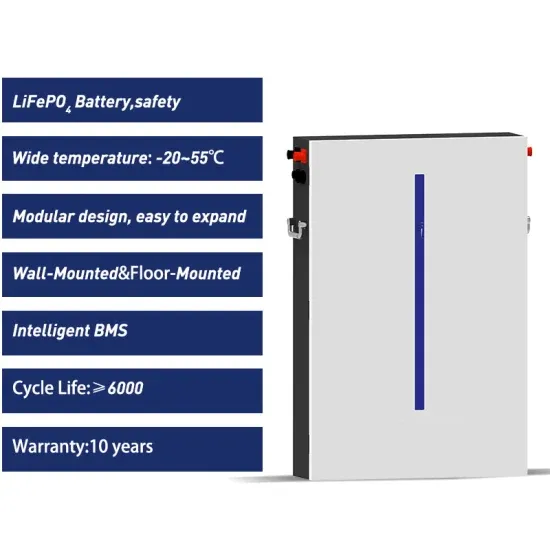

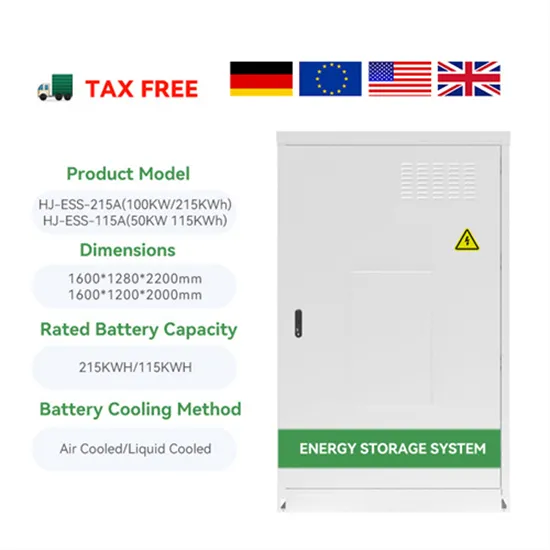

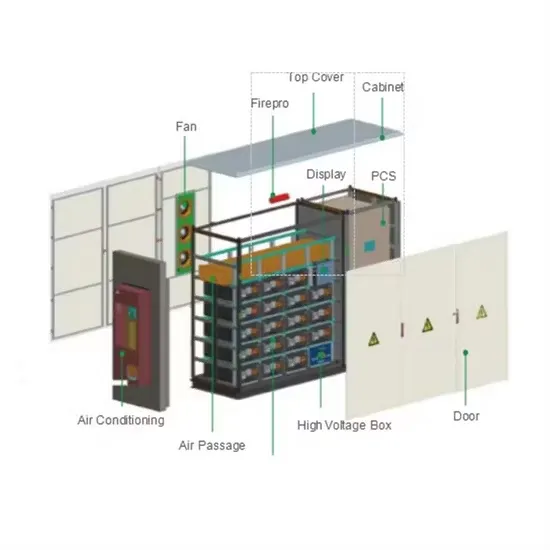

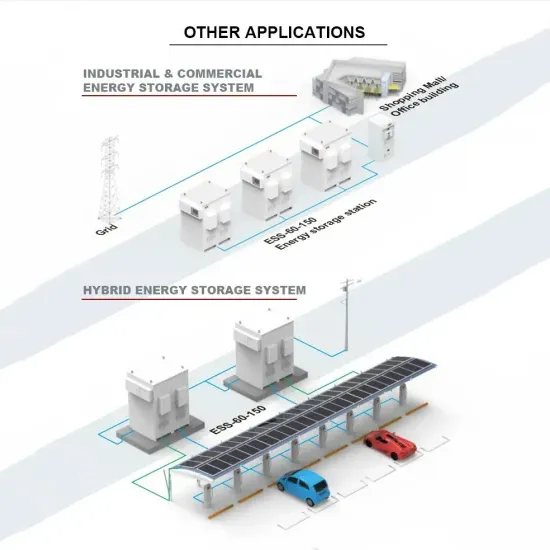

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

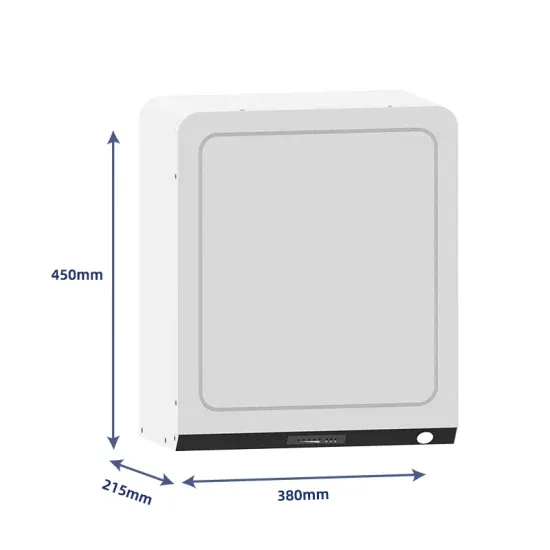

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.