T1 Energy''s (FKA FREYR) new 5 GW US solar factory leaps forward

T1 Energy, formerly FREYR Battery, kicks off preparations for its new solar cell factory, set to be one of the largest in the US.

Get a quote

Cost of electricity by source

Levelized cost: With increasingly widespread implementation of renewable energy sources, costs have declined, most notably for energy generated by solar

Get a quote

Solar Panel Manufacturing Cost: A Complete Factory

Starting a solar panel factory? Get a detailed cost breakdown for machinery, buildings, and working capital for 25 MW, 100 MW, and 800 MW

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled.

Get a quote

Wholesale Solar Powered Vending Machine Products at Factory Prices

Find wholesale solar powered vending machine manufacturers from China, India, Korea, and so on. Source good quality solar powered vending machine products for sale at factory prices

Get a quote

Cost of electricity by source

Solar power was by far the most expensive renewable source of electricity among the technologies studied, although increasing efficiency and longer lifespan of photovoltaic panels

Get a quote

Solar Photovoltaic System Cost Benchmarks

These benchmarks help measure progress toward goals for reducing solar electricity costs and guide SETO research and development programs. Read

Get a quote

Solar Panel Manufacturing Cost: A Complete Factory Breakdown

Starting a solar panel factory? Get a detailed cost breakdown for machinery, buildings, and working capital for 25 MW, 100 MW, and 800 MW production lines.

Get a quote

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are

Get a quote

How much is the factory price of solar energy | NenPower

The term "factory price" typically refers to the manufacturing cost of components, packages, and systems that convert solar light into usable energy. This manufacturing process

Get a quote

Solar Industry Research Data – SEIA

Growth in Solar is Led by Falling Prices Solar installation price drops over the last decade have made solar economically competitive with other sources of

Get a quote

U.S. solar manufacturing moving onshore and prospering

Efforts to establish solar manufacturing in the United States, on the back of generous Inflation Reduction Act subsidies, have had mixed

Get a quote

How Much Does It Cost to Start a Solar Panel

Building a manufacturing facility could range from $500,000 to several million dollars, depending on size and technology. Equipment such as solar cell

Get a quote

Solar (photovoltaic) panel prices

IRENA presents solar photovoltaic module prices for a number of different technologies. Here we use the average yearly price for technologies ''Thin film a-Si/u-Si or

Get a quote

Solar Power for Factories | Solaric Corporation

Discover the benefits of solar power for factories in the Philippines. Cut energy costs, boost efficiency, and support a greener future with Solaric.

Get a quote

Tesla just launched the Megablock, a big, | Canary Media

3 days ago· Tesla timed the unveiling for the opening night of RE +, the bustling solar and clean energy industry conference, but hosted it on Musk-affiliated turf: a station for his side project

Get a quote

Solar Plant Setup Cost in India: 1MW, 2MW, 5MW

Solar Power Plant Setup Cost Overview Solar power plants are becoming a preferred energy solution for industrial and commercial users in India due to

Get a quote

How Much Does Solar Energy Cost?

How Much Does Solar Energy Cost? With rising energy bills and climate change concerns, many homeowners and businesses are considering installing solar panels. But what

Get a quote

Wind and Solar Energy Are Cheaper Than Electricity

Persistently low natural gas prices, rising renewable energy costs and higher electricity demand have made existing gas plants economically

Get a quote

Solar Technology Cost Analysis | Solar Market

Solar Technology Cost Analysis NREL''s solar technology cost analysis examines the technology costs and supply chain issues for solar

Get a quote

Cost of Setting Up a Solar Panel Manufacturing Plant

Learn how to plan capital investment, manage raw material costs, post manufacturing cost and optimize operations for setting up solar panel plant.

Get a quote

What Are the 9 Operating Costs of a Solar Panel Manufacturing

High-tech production lines backed by automation and AI can require upwards of $2 million to $5 million, depending on the plant''s scale. This cost falls under the overall solar

Get a quote

Solar Photovoltaic System Cost Benchmarks

These benchmarks help measure progress toward goals for reducing solar electricity costs and guide SETO research and development programs. Read more to find out how these cost

Get a quote

U.S. Solar Photovoltaic System and Energy Storage Cost

This work was authored in part by the National Renewable Energy Laboratory, operated by Alliance for Sustainable Energy, LLC, for the U.S. Department of Energy (DOE) under

Get a quote

First Solar

First Solar, Inc. is a publicly traded American manufacturer of solar panels, and provider of utility-scale PV power plants, supporting services that include finance, construction, maintenance

Get a quote

How Much Do Industrial Solar Panels Cost?

By determining the cost of solar power, businesses can evaluate the potential subsidies and tax incentives they may receive. Typically, before tax subsidies

Get a quote

Cost of electricity by source

OverviewRegional studiesCost metricsCost factorsGlobal studiesSee alsoFurther reading

In 2020, BNEF estimated the following costs for electricity generation in Australia: It can be seen from the following table that the cost of renewable energy, particularly photovoltaics, is falling very rapidly. As of 2017, the cost of electricity generation from photovoltaics, for example, has fallen by almost 75% within 7 years. In the United Kingdom, a feed-in tariff of £92.50/MWh at 2012 prices (currently the equivalent of

Get a quote

How Much Does It Cost to Start a Solar Panel Manufacturing Plant?

Building a manufacturing facility could range from $500,000 to several million dollars, depending on size and technology. Equipment such as solar cell production lines, laminators, and testing

Get a quote

Photovoltaic power station

Photovoltaic power station The 40.5 MW Jännersdorf Solar Park in Prignitz, Germany A photovoltaic power station, also known as a solar park, solar farm,

Get a quote

How Much Do Industrial Solar Panels Cost?

By determining the cost of solar power, businesses can evaluate the potential subsidies and tax incentives they may receive. Typically, before tax subsidies and rebates, the cost of

Get a quote

6 FAQs about [Solar field energy source factory price]

What are solar panel manufacturing costs?

These costs encompass everything from equipment and labor to raw materials and operational expenses. In short, starting a solar panel manufacturing plant involves a complex web of financial considerations that must be navigated to ensure success. Overview of solar panel manufacturing costs. Breakdown of capital expenses.

What are the costs associated with R&D in a solar panel manufacturing facility?

The costs associated with R&D in a solar panel manufacturing facility can vary significantly, but they typically include: Laboratories and Facilities: Costs for maintaining and equipping laboratories for testing and development. Prototyping: Expenses related to creating prototypes of new solar panel designs or technologies.

How much do solar panels cost?

High-tech production lines backed by automation and AI can require upwards of $2 million to $5 million, depending on the plant’s scale. This cost falls under the overall solar panel manufacturing costs that also include equipment depreciation in solar plants. The solar panel production cost also hinges on the price of raw materials.

How much does it cost to build a solar plant?

To give you a clearer picture, let’s consider the costs involved. Building a manufacturing facility could range from $500,000 to several million dollars, depending on size and technology. Equipment such as solar cell production lines, laminators, and testing machines can add hundreds of thousands to your budget.

How much does Solartech innovation cost?

SolarTech Innovations faces significant initial investments in machinery and technology. High-tech production lines backed by automation and AI can require upwards of $2 million to $5 million, depending on the plant’s scale. This cost falls under the overall solar panel manufacturing costs that also include equipment depreciation in solar plants.

How does energy management affect solar panel manufacturing costs?

It impacts the overall solar panel manufacturing costs significantly. For instance, energy expenses can account for up to 30% of total operational costs in similar facilities. Therefore, using energy-efficient equipment and implementing regular energy audits becomes essential for managing solar panel plant expenses.

Guess what you want to know

-

Solar on-site energy source factory

Solar on-site energy source factory

-

Solar spherical field energy communication power supply price

Solar spherical field energy communication power supply price

-

Price of new solar energy storage cabinet

Price of new solar energy storage cabinet

-

Solar Energy Storage Cabinet Smart Interconnected Factory

Solar Energy Storage Cabinet Smart Interconnected Factory

-

Factory price of local energy storage power supply in Israel

Factory price of local energy storage power supply in Israel

-

Is there a lifetime solar energy source in China

Is there a lifetime solar energy source in China

-

New Energy Solar Panel Factory

New Energy Solar Panel Factory

-

What is the price of distributed energy storage cabinet factory in Guinea-Bissau

What is the price of distributed energy storage cabinet factory in Guinea-Bissau

-

Singapore Energy Storage Power Source Factory

Singapore Energy Storage Power Source Factory

-

Price of solar energy application system in Macedonia

Price of solar energy application system in Macedonia

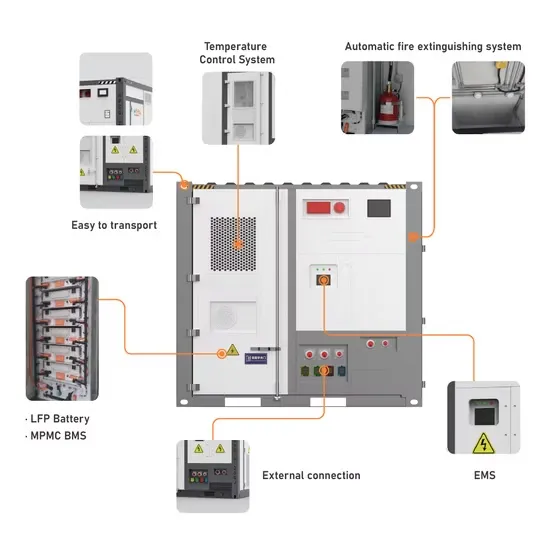

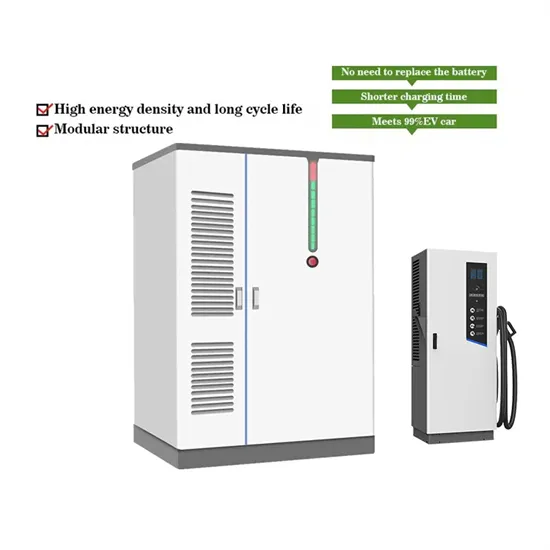

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.