batteries

If you put batteries in parallel, you increase their maximum current proportionally, without changing the voltage. If you put them in series - you increase the voltage, without

Get a quote

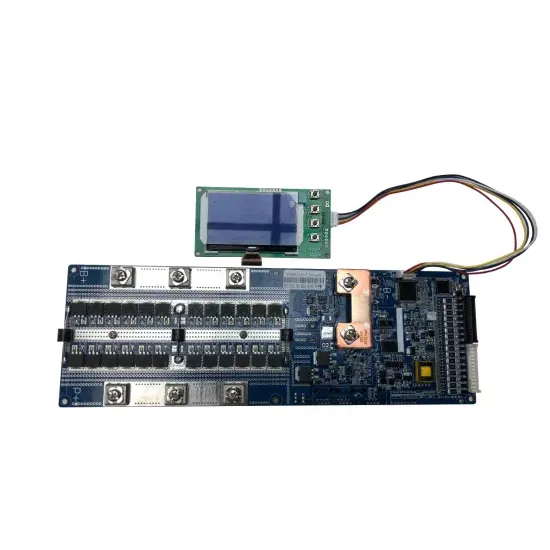

Bidirectional Active Equalization Control of Lithium Battery Pack

Aiming at the energy inconsistency of each battery during the use of lithium-ion batteries (LIBs), a bidirectional active equalization topology of lithium battery packs based on

Get a quote

How Load Current Affects a Lithium-Ion Battery''s

There are four methods to account for load current in capacity and runtime calculations accurately. The best one is to generate empirical cycling

Get a quote

How Many Cells in a Lithium Battery Pack? A Complete Guide to

Lithium batteries use multiple cells. For example, a lithium-ion battery has 3 cells for 11.1 volts, 4 cells for 14.8 volts, or 10 cells for 37 volts. Cells can be arranged in series to

Get a quote

Everything About Lithium Battery Series & Parallel

Lithium battery series connection is to connect multiple batteries end to end, with the positive electrode connected to the negative electrode of

Get a quote

What is the maximum current which can pass in a

I am connecting a load to a Li-ion battery (4.2V), but I don''t know how much maximum current can pass through a Li-ion battery. When I know it, I will

Get a quote

Does a Battery Pack Increase Current? Insights on Connecting

No, a battery pack does not inherently increase the current output of a system. The current output is primarily determined by the load and the configuration of the battery pack. A

Get a quote

Optimal Lithium Battery Charging: A Definitive Guide

Charging a lithium battery pack may seem straightforward initially, but it''s all in the details. Incorrect charging methods can lead to reduced battery capacity, degraded

Get a quote

The Main Factors Determine The Capacity Lithium

Therefore, it is crucial to select the appropriate charging rate, upper voltage limit, and constant voltage cutoff current to ensure optimal charging

Get a quote

Voltage vs Amperage in Lithium Batteries: Key Differences

Can I increase the amperage output from my lithium-ion battery? While you can''t increase a single cell''s amperage, connecting multiple cells in parallel configurations safely

Get a quote

A Complete Guide to Understanding Battery Packs

Battery packs come in many types, each suited to different needs and applications. Whether it''s for a smartphone, electric vehicle, or a portable

Get a quote

Lithium‐based batteries, history, current status,

The operational principle of the rechargeable battery is centered on a reversible redox reaction taking place between the cathode (positive

Get a quote

Ultimate Guide of LiFePO4 Lithium Batteries in Series

In a series connection, the voltage output of the battery pack increases, while in a parallel connection, the capacity increases. ② Use in various applications:

Get a quote

Optimization of lithium-ion battery pack thermal performance: A

This study fills that void by thoroughly examining how battery tabs, busbars, electrical configurations (series–parallel), and discharge rates collectively influence both

Get a quote

Can You Use a Battery Pack with Higher Battery Management

A Battery Management System (BMS) plays a critical role in protecting your battery from overcharging, over-discharging, and overheating, thus extending the lifespan and

Get a quote

5 differences between capacity lithium battery and the power one

Power lithium battery pack supports high current discharge, the instantaneous discharge volume is large and may reach 30C times the current; ordinary capacity lithium

Get a quote

Connecting batteries in series – BatteryGuy Knowledge Base

Connecting batteries of different amp hour ratings in series In theory a 6 volt 3 Ah battery and a 6 volt 5 Ah battery connected in series would give a supply of 12 volts 3 Ah (the

Get a quote

The Relationship and Differences Between Voltage

Excessive current can lead to overheating and potential battery failure, while insufficient current may not meet the device''s power requirements. Voltage

Get a quote

Analysis of the Charging and Discharging Process of

In these types of devices, lithium-ion batteries are commonly used nowadays, and in particular their variety—lithium iron phosphate

Get a quote

The Main Factors Determine The Capacity Lithium Battery Pack.

Therefore, it is crucial to select the appropriate charging rate, upper voltage limit, and constant voltage cutoff current to ensure optimal charging capacity while maintaining

Get a quote

How Load Current Affects a Lithium-Ion Battery''s Capacity and

There are four methods to account for load current in capacity and runtime calculations accurately. The best one is to generate empirical cycling data at the desired

Get a quote

The Relationship and Differences Between Voltage and Current in Lithium

Excessive current can lead to overheating and potential battery failure, while insufficient current may not meet the device''s power requirements. Voltage and current are related through

Get a quote

How to Read Lithium Battery Discharge and Charging

The performance of lithium batteries is crucial for operating various electronic devices and electric tools. Lithium batteries'' discharge and charge

Get a quote

Battery Pack Designer''s Guide: From Beginner to Pro [With

Custom lithium-ion battery packs provide superior output characteristics and extended operational life compared to standard solutions. Design optimization focuses on achieving maximum

Get a quote

Optimal Lithium Battery Charging: A Definitive Guide

Charging a lithium battery pack may seem straightforward initially, but it''s all in the details. Incorrect charging methods can lead to reduced

Get a quote

Can You Use a Battery Pack with Higher Battery Management

Learn the effects of using a battery pack with higher BMS amps for better performance and safety. Discover compatibility tips here.

Get a quote

6 FAQs about [Lithium battery pack increases output current]

What is the relationship between voltage and current in lithium ion batteries?

Voltage and current are essential parameters for assessing the performance of lithium-ion batteries. Voltage determines whether a device can operate, while current dictates the energy transfer rate and runtime. Understanding their relationship and differences is crucial for safe and efficient battery use.

What factors affect the performance and life of a lithium battery pack?

Several factors play a critical role in the performance and life of a lithium battery pack. One crucial consideration is cycle life, which refers to the number of charge/discharge cycles a battery can undergo before its capacity drops significantly.

How does voltage affect energy capacity of a lithium-ion battery?

Device Compatibility: Different devices operate at specific voltages. Knowing the voltage of a lithium-ion battery ensures it can power a device without causing damage or underperformance. Energy Wh =Voltage V ×Capacity Ah This relationship highlights how voltage directly affects the overall energy capacity of the battery. Part 2.

Does charging a lithium ion battery change the voltage?

Measured with an ammeter to check the flow of current. Does Charging or Discharging Change a Lithium-Ion Battery’s Voltage? Yes, the voltage of a lithium-ion battery changes with its State of Charge (SOC): During charging: Voltage gradually increases and stabilizes at around 4.2V when fully charged.

What happens if you run a lithium ion battery below recommended voltage?

Operating below recommended voltages may cause reduced performance or prevent devices from functioning; prolonged low-voltage operation could damage cells over time. Lithium-ion batteries power modern devices. Voltage drives current, while amperage measures flow, both crucial for performance and efficiency.

What factors influence the thermal behavior of lithium-ion battery packs?

The findings affirm that the discharge rate is the most influential parameter shaping the thermal behavior of lithium-ion battery packs. The thermal properties of a battery pack are greatly affected by its electrical setup, standing as the second most influential factor.

Guess what you want to know

-

How much current should a 40ah lithium battery pack be charged with

How much current should a 40ah lithium battery pack be charged with

-

12v lithium battery pack output voltage

12v lithium battery pack output voltage

-

Lithium battery pack buck output module

Lithium battery pack buck output module

-

72v lithium battery pack output 2 8 volts

72v lithium battery pack output 2 8 volts

-

30Ah lithium battery pack

30Ah lithium battery pack

-

Moldova large single lithium battery pack

Moldova large single lithium battery pack

-

Lithium battery pack low temperature

Lithium battery pack low temperature

-

6 series 4 parallel 24v lithium battery pack

6 series 4 parallel 24v lithium battery pack

-

Mongolia lithium battery pack processing

Mongolia lithium battery pack processing

-

5v lithium battery pack with large capacity

5v lithium battery pack with large capacity

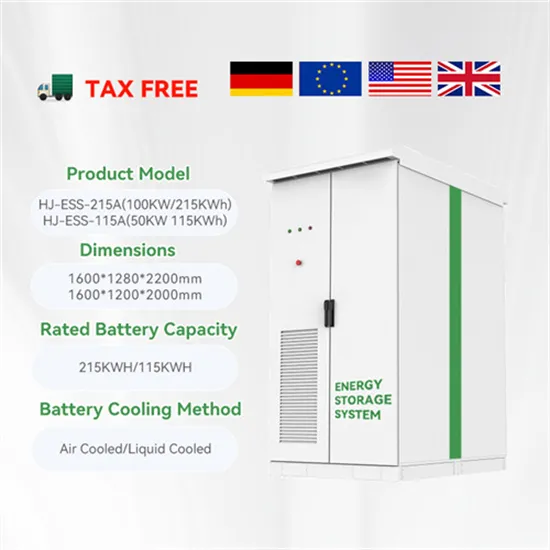

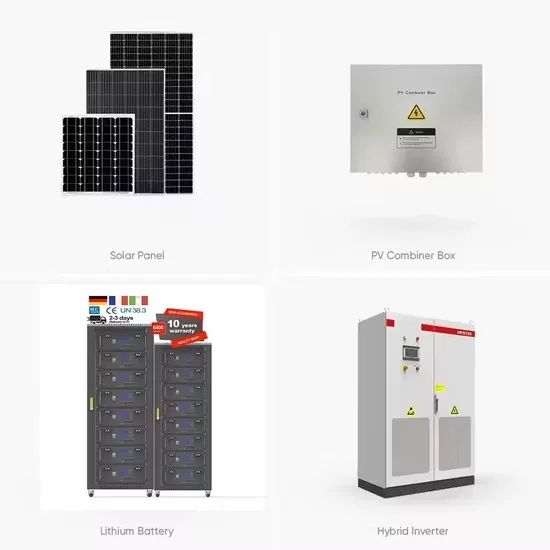

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.