Battery Protection ICs for Multi-cell Pack

Battery protection ICs protect batteries from hazards such as overcharging, overdischarging and overcurrent. ABLIC has been developing and producing battery protection ICs since 1993, and

Get a quote

Protecting Your Lithium-Ion Batteries Isn''t So Hard.

For safety purposes, some protection circuitry must be incorporated when lithium batteries are designed into a product. This article discusses one approach to battery protection.

Get a quote

Keeping Higher Current Lithium-ion Battery Cells Safe with

In light of such obvious hazards, cell designers should take a multi-layer protection approach. Individual cells require mechanical, electrical and thermal protection, and designers have

Get a quote

Battery Pack Safety

There are usually 3 levels of protection against overcharge built into devices using Lithium-ion batteries; Internal devices inside individual cells in a battery pack A "protection" circuit built into

Get a quote

Protection Circuit Modules for Custom Battery Packs

Protection circuits embedded into battery packs provide full-time protection that is active throughout the lifecycle of the battery. This design method is generally used for rechargeable

Get a quote

Risk evaluation of internal short circuit for lithium‐ion battery

Risk evaluation of internal short circuit for lithium-ion battery based on an active protection method Wenji Song, Guangzhou Institute of Energy Conversion, Chinese Academy

Get a quote

Multi-level current protection method for lithium battery pack

In their study, following a multi-module charger, a user-involved methodology with the leader-followers structure is developed to control the charging of a series-connected lithium-ion

Get a quote

A Power Management IC Used for Monitoring and Protection of

A power management system is a critical component of the system which needs Li-ion battery packs for power supply. This paper proposes a fully integrated, high-precision, and

Get a quote

Products Center

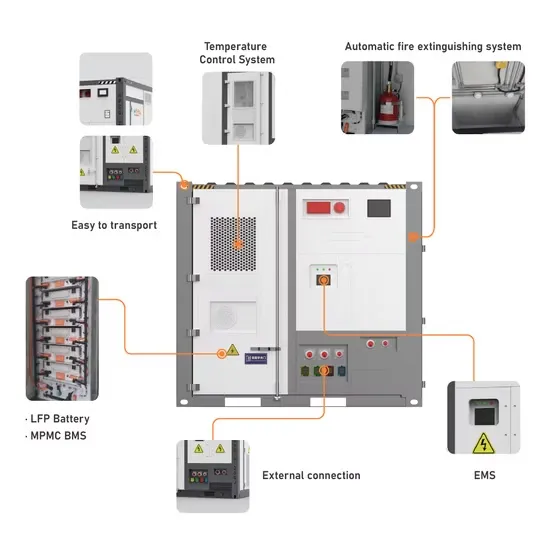

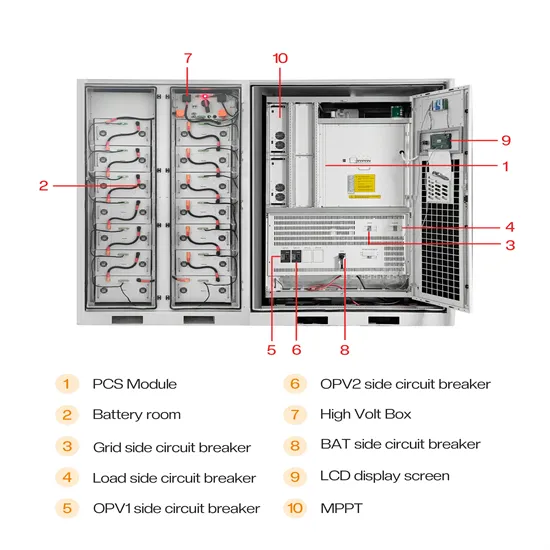

A cabinet-level management system (CBMS) is responsible for battery current detection, data collection and analysis, alarm and protection control, and upper- and lower-level communication.

Get a quote

Battery Protection Circuit of Different Battery Chemistries and

Protection circuits act as a safeguard by detecting abnormal current levels and disconnecting the battery from the load. This feature is especially crucial in lithium-ion

Get a quote

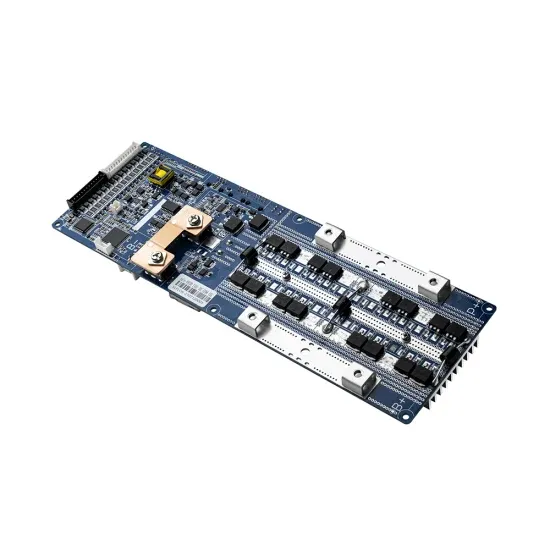

10s-16s Battery Pack Reference Design With Accurate Cell

Description This reference design is a low standby and ship-mode current consumption and high cell voltage accuracy 10s–16s Lithium-ion (Li-ion), LiFePO4 battery pack design. It monitors

Get a quote

How to Accurately Check Your Battery Charge Level

Your battery charge level depends on your device, usage, and charging habits. Most smartphones, laptops, and EVs display charge percentages, but accuracy varies. Many

Get a quote

Lithium Battery Pack Protection and Control

Safety and ageing concerns in Lithium battery applications highlight the critical need for advanced protection and control solutions in the market. Adoption of electric vehicles, both in the

Get a quote

Battery protectors | TI

We understand performance and safety are major care-abouts for battery packs with lithium-based (li-ion and li-polymer) chemistries. That is why we design our battery protection ICs to

Get a quote

Battery protectors | TI

That is why we design our battery protection ICs to detect a variety of fault conditions including overvoltage, undervoltage, discharge overcurrent and short circuit in single-cell and multi-cell

Get a quote

Improved voltage transfer method for lithium battery

In order to cut the costs and overcome the leakage current of batteries caused in traditional method, this study introduces an improved

Get a quote

Lithium battery pack temperature control circuit

The thermal effect must be considered in battery models. In this paper, a simulation model of a lithium battery with thermal characteristics is established. This thermal model is coupled with a

Get a quote

Research on overcharge mitigations and thermal runaway risk of

The safety issues of lithium-ion batteries are becoming increasingly severe, and overcharging is one of the primary abuse conditions that can lead to safety incidents in lithium

Get a quote

Protection Circuit Modules for Custom Battery Packs

In light of such obvious hazards, cell designers should take a multi-layer protection approach. Individual cells require mechanical, electrical and thermal protection, and designers have

Get a quote

Battery protection selection guide

Consequently, such batteries require special care in stressful conditions such as overcharge, undercharge, short circuits, overheat, etc. For that, Infineon ofers a wide range of battery

Get a quote

Multi-Cell Battery Sensing and Protection IC With Integrated Low

These BMICs incorporate functions such as battery sensing, fault detection, and protection management. This paper introduces an 18-cell lithium-ion battery sensing and

Get a quote

Lithium Battery Fire Protection | Pyrophobic Systems

Material-Driven Prevention: Beyond Traditional Suppression Traditional fire suppression methods, like water or foam sprinklers, often prove

Get a quote

Protecting Your Lithium-Ion Batteries Isn''t So Hard.

For safety purposes, some protection circuitry must be incorporated when lithium batteries are designed into a product. This article

Get a quote

Research progress on early warning method and suppression

This work by analyzing the evolution of surface temperature, space temperature, and voltage of ternary lithium battery pack under different overcharging rates, a three-level

Get a quote

Battery Protection ICs for Multi-cell Pack

Battery protection ICs protect batteries from hazards such as overcharging, overdischarging and overcurrent. ABLIC has been developing and producing

Get a quote

Battery Pack Safety

Used to limit currents in an over-charge condition (tripped by heat). Also used to limit short circuit currents from a single cell to a safe level. In case of large internal pressure buildup (under

Get a quote

Lithium-Ion Battery Fire Suppression in EVs

1. Localized Fire Suppression Using Embedded or Adjacent Devices Thermal runaway events in EV battery systems present a fundamental safety challenge: once initiated

Get a quote

6 FAQs about [Multi-level current protection method for lithium battery pack]

What type of batteries does this protection circuit apply to?

This protection circuit is generally used for rechargeable lithium batteries and where there will be multiple cells within the battery pack. Protection circuits embedded into battery packs provide full-time protection that is active throughout the lifecycle of the battery.

Can this protection circuit module be used with non-lithium batteries?

This protection circuit module can also function using non-lithium battery chemistries that do not require a protection circuit when in use or when discharging. Some advantages with having the protection circuit module in the battery charger is that only one protection circuit module will be required, and it can reduce costs when using multiple batteries.

Why do you need a battery protection IC?

That is why we design our battery protection ICs to detect a variety of fault conditions including overvoltage, undervoltage, discharge overcurrent and short circuit in single-cell and multi-cell batteries, so you can enhance the safety of your battery pack.

How hard is it to protect a lithium-ion battery?

Protecting Your Lithium-Ion Batteries Isn’t So Hard. Sponsored by: Texas Instruments Safety is a primary concern when using lithium-battery technology—here's one approach to implementing the level of protection needed in battery packs for portables.

What are lithium-ion and lithium-polymer batteries?

Lithium-ion and lithium-polymer batteries are increasingly finding their way into portable and mobile devices. These highly efficient battery technologies pack more energy into a smaller size than almost any other battery type.

What is a protection circuit?

A protection circuit is a component embedded into battery packs that provides full-time protection throughout the lifecycle of the battery.

Guess what you want to know

-

How much current should a 40ah lithium battery pack be charged with

How much current should a 40ah lithium battery pack be charged with

-

Lithium battery pack increases output current

Lithium battery pack increases output current

-

Charging method of a lithium battery pack

Charging method of a lithium battery pack

-

Charging of lithium battery pack with protection

Charging of lithium battery pack with protection

-

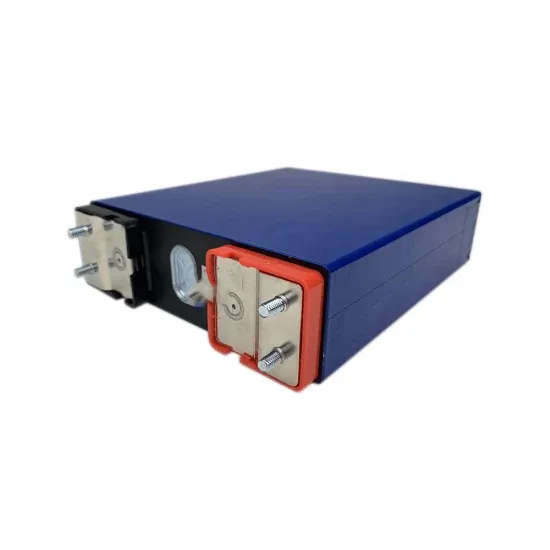

Turkey lithium iron phosphate battery pack

Turkey lithium iron phosphate battery pack

-

Which lithium battery pack manufacturer in Peru is the best

Which lithium battery pack manufacturer in Peru is the best

-

Chilean single lithium battery pack

Chilean single lithium battery pack

-

How much does a 60v 200AH lithium iron phosphate battery pack cost

How much does a 60v 200AH lithium iron phosphate battery pack cost

-

Which lithium battery pack is better in Nicaragua

Which lithium battery pack is better in Nicaragua

-

Lithium battery pack factory voltage

Lithium battery pack factory voltage

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.