Cutting-edge Technology In Photovoltaic Inverters—heat Dissipation

To design a heat dissipation system, first calculate the heat generated by the inverter. The main sources of heat are power switch transistors, filter inductors, and transformers.

Get a quote

What is the heat dissipation temperature of photovoltaic inverter

Similarly the PV inverter component temperature can be calculated by: (1) T C = T A +D T H +D T Cwhere T A is ambient temperature,D T H is heat sink temperature rise,D T C is component

Get a quote

SolarEdge System Design and the NEC

The amount of heat generated by the inverter depends on its model type and on the amount of power it is generating at any given time. The numbers in the tables below describe the peak

Get a quote

Photovoltaic inverter heat dissipation requirements

Efficient heat dissipation: The heat dissipation design should ensure that the heat generated by the inverter during operation can be

Get a quote

Enhancement of photovoltaic module performance using passive

The primary application of solar energy is in the generation of electricity through photovoltaic (PV) systems. Solar panels with photovoltaic cells convert sunlight directly into

Get a quote

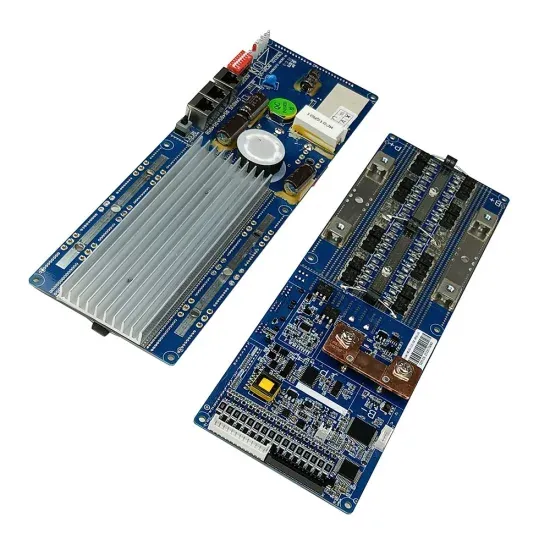

Photovoltaic-inverter heat-dissipation assembly

A photovoltaic-inverter heat-dissipation assembly (1, 1a, 1b, 1c) is disclosure and includes a front housing-base (10), a rear cover (20), a first heat-generating device (32), a first fan (33), a

Get a quote

Heat-dissipation performance of photovoltaic panels with a phase

In this study, a phase-change material (PCM) is used to cool the PV panels, and fins are added to enhance PCM heat transfer. Using numerical simulation, the effects of fin

Get a quote

Thermal Analysis and Design Optimization of Photovoltaic

The performance of a photovoltaic (PV) module is largely dependent on the temperature of the PV cell. Hence, heat management in a PV module is crucial to improving the performance and

Get a quote

What is the heat dissipation used for photovoltaic inverters

A method for modeling inverter temperature as a function of the operating conditions is proposed. A thermal model is demonstrated for predicting average inverter heat-sink temperatures. The

Get a quote

Photovoltaic inverter is too hot? You need to give it a

Photovoltaic inverter as the core of photovoltaic power station, its life affects the normal operation of the whole power station, and the heat

Get a quote

How to best dissipate heat from photovoltaic inverters

r dissipates the heat through fans and /or heat sinks. The heat needs to stay below a certain level at whi. h the materials in the inverter will start.

Get a quote

CN111988967A

The invention provides a photovoltaic inverter heat dissipation structure and a method thereof, wherein the heat dissipation structure comprises a shell, a panel arranged at the front part of

Get a quote

Cutting-edge Technology In Photovoltaic

To design a heat dissipation system, first calculate the heat generated by the inverter. The main sources of heat are power switch transistors, filter

Get a quote

Thermal Design of Photovoltaic Power Generation Inverter

Thermal analysis of DC/DC and DC/AC that is two main heat sources in 10kW photovoltaic power generation inverter are be carried out. Under full load, the thermal characteristics of inverter

Get a quote

Photovoltaic Inverter Enclosure Heating and Cooling Principle

4 days ago· Learn why solar inverter enclosures get hot, how heat dissipation works, and why a warm enclosure can actually protect inverter components and extend system lifespan.

Get a quote

What is the heat dissipation temperature of photovoltaic inverter

What happens if a PV inverter gets too hot? For every 1 degree Celsius or approximately 2 degrees Fahrenheit that the temperature rises,the inverter''s capacity would drop by 0.5%If

Get a quote

GoodWe: The secret of heat dissipation for photovoltaic inverters

However, the heat dissipation of the inverter is an issue that photovoltaic industry tends to ignore, and heat dissipation is precisely what needs to be focused on.

Get a quote

Heat Dissipation in Solar Inverters

Solar inverters play a critical role in converting direct current generated by solar panels into alternating current suitable for household or industrial use. One of the key

Get a quote

What is the heat dissipation temperature of photovoltaic inverter

As the photovoltaic (PV) industry continues to evolve, advancements in What is the heat dissipation temperature of photovoltaic inverter have become critical to optimizing the

Get a quote

Synthetical Thermal Modeling and Optimization Design for High

Demanding accuracy and reliability of thermal design for high efficiency and high-power density inverter devices. Integrating heat conduction, convection heat transfer and fluid dynamics

Get a quote

Photovoltaic inverter heat dissipation requirements

Efficient heat dissipation: The heat dissipation design should ensure that the heat generated by the inverter during operation can be dissipated in time and effectively, and keep

Get a quote

Photovoltaic inverter heat dissipation mode and precautions

The correct heat dissipation mode of photovoltaic inverters can effectively extend the service life of the equipment and improve its work efficiency. Now let''s specifically

Get a quote

Evolution of Solar Inverter Cooling System: From Air Cooling to

Analyze the fourth generation of heat dissipation technology revolution in photovoltaic inverters, dismantle the evolution path of heat dissipation solutions, the

Get a quote

Guess what you want to know

-

Heat dissipation characteristics of photovoltaic panels

Heat dissipation characteristics of photovoltaic panels

-

Photovoltaic curtain wall heat dissipation

Photovoltaic curtain wall heat dissipation

-

Huawei Venezuela heat dissipation photovoltaic panels

Huawei Venezuela heat dissipation photovoltaic panels

-

Photovoltaic 275w inverter

Photovoltaic 275w inverter

-

Photovoltaic central inverter price

Photovoltaic central inverter price

-

Solar thermal photovoltaic water pump inverter

Solar thermal photovoltaic water pump inverter

-

Belize Distributed Photovoltaic Inverter Plant

Belize Distributed Photovoltaic Inverter Plant

-

Nigeria photovoltaic and wind power inverter manufacturers

Nigeria photovoltaic and wind power inverter manufacturers

-

How high should the photovoltaic inverter be from the ground

How high should the photovoltaic inverter be from the ground

-

Photovoltaic inverter power conversion

Photovoltaic inverter power conversion

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.