EFFECTIVE GROUNDING FOR PV PLANTS

When a PV plant is installed in the distribution feeder, the plant shall meet the IEEE 1547 standard and the interface requirements of the local utility company. Some utility companies

Get a quote

Ground Mounted Solar Panels: How Far Is Too Far

Ground Mounted Solar Panels. Explore the factors that influence panel performance, such as energy loss and shading issues. Learn how to optimize

Get a quote

How to Ground a Photovoltaic Inverter?

Grounding a photovoltaic inverter is a preparatory step before making electrical connections. Before connecting the inverter electrically, it is crucial to ensure that the inverter''s

Get a quote

Ground-Mounted Solar Panels: What You Need To Know

Ground-mounted solar panels are a great alternative for customers who want solar – but don''t have a roof that''s suitable for them. On top of being an

Get a quote

Best Practices for Operation and Maintenance of

O&M depends on the topology of the inverter system: micro-inverters on each module, string inverters on series strings of modules, DC-optimized inverters that combine elements of both

Get a quote

Grounding Methods for Photovoltaic Lightning Protection

Proper grounding is a critical safety measure for photovoltaic (PV) systems. With advances in solar technology, companies like Bluesun Solar are leading the

Get a quote

PV Problem Troubleshooting: Arrays, Batteries, Inverters & More

This article examines troubleshooting for photovoltaic system issues related to arrays, electrical loads, batteries, charge controllers, and inverters.

Get a quote

Inverter height | Information by Electrical Professionals for

In summary, you should be allowed to install an inverter with an integrated disconnect at a higher level if you provide an additional safety switch that is less than 6''-7"

Get a quote

Where is the best place to install an inverter?

The location of the inverter is quite an important issue, which should be decided at the design stage of the photovoltaic installation. This is because the location of the inverter

Get a quote

Field Guide for Testing Existing Photovoltaic Systems for

This report provides field procedures for testing PV arrays for ground faults, and for implementing high-resolution ground fault and arc fault detectors in existing and new PV system designs.

Get a quote

How to install ground-mounted solar panels (The 5

Here are the five steps for a DIY installation of ground-mounted solar panels: Select the best spot for your ground-mounted solar panels.

Get a quote

Photovoltaic inverter mounting height | Information by Electrical

That switch is required to be less than two meters (6''-7") high (see 404.8) unless there is another switch that meets the requirements of 690.14 (C) (1). A second issue is that

Get a quote

Grounding and Methods of Earthing in PV Solar System

In high-power generators, ground protection should be provided at the main grounding system. Ensure that cables and wires (both AC and DC) are sized according to the fuse/circuit breaker

Get a quote

EFFECTIVE GROUNDING FOR PV PLANTS

Sequence network analysis and intensive PV inverter computer model simulation show that the worst case overvoltage can be limited to about 130% of its nominal value by following this

Get a quote

Photovoltaic inverter grounding tips

What is effective grounding in photovoltaic (PV) systems? Effective grounding in photovoltaic (PV) systems is the creation of a low-impedance reference to ground at the AC side of the inverter-

Get a quote

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

Solar PV system inverters can be quite heavy (>80 pounds), necessitating a solid backing to mount the inverter. Pre-installing a 4'' x 4'' piece of finished plywood provides the future solar

Get a quote

Grounding and Methods of Earthing in PV Solar System

In high-power generators, ground protection should be provided at the main grounding system. Ensure that cables and wires (both AC and DC) are sized

Get a quote

How high should the photovoltaic inverter be from the ground

From what I''''ve read the general consensus for 12V DC off-grid systems seems to be that you should run a ground wire from components such as the Inverter and MPPT

Get a quote

Where to Put Solar Inverter – Optimal Placement Guide

Discover the ideal location for your solar inverter with our comprehensive guide, ensuring maximum efficiency and optimal performance

Get a quote

What Is the Average Height of Ground Mounted Solar Panels?

Ground-mounted solar panels are typically installed at a height that balances efficiency with practicality. The average height generally ranges from 3 to 5 feet above the

Get a quote

How to Ground a Photovoltaic Inverter?

How to Ground a Photovoltaic Inverter? Grounding a photovoltaic inverter is a preparatory step before making electrical connections. Before connecting the inverter

Get a quote

Do You Need To Ground An Inverter? (Safe Measures)

How to Ground a Photovoltaic Inverter? Grounding a photovoltaic inverter is a preparatory step before making electrical connections. Before

Get a quote

Do You Need To Ground An Inverter? (Safe Measures)

Inverters should always be grounded to a single grounding point. A copper grounding rod must be driven into the ground outside and connected to the single grounding

Get a quote

Technical Information

For larger cross-sections of the line conductors up to 35 mm2, the grounding conductor must be at least 16 mm2. For cross-sections larger than 35 mm2, the grounding conductor must have

Get a quote

Photovoltaic System Grounding

He installed his first photovoltaic (PV) power system in 1984 and has been involved in the design, installation, inspection, and testing of PV systems for 28 years. He is a member of the

Get a quote

Where to Put Solar Inverter – Optimal Placement Guide

Discover the ideal location for your solar inverter with our comprehensive guide, ensuring maximum efficiency and optimal performance for your solar system.

Get a quote

6 FAQs about [How high should the photovoltaic inverter be from the ground ]

How a solar inverter is connected to a PV system?

The inverter is connected to the single ground rod used for both AC and DC using the GEC. While the PV array and inverter is connected to the main grounding terminal in the main panel through he EGC. In this grounding method, a single copper ground rod is used for both AC system and DC solar panel system using combined DC GEC and AC EGC.

Do inverters need to be grounded?

If there is no suitable grounding connection point, then the grounding wire from the inverter must be connected to the negative terminal of the battery bank for off-grid systems. For Grid-tied systems, the inverter grounding is more complex and should be done by a qualified electrician.

Do PV inverters need AC side grounding?

When a PV plant is installed in the distribution feeder, the plant shall meet the IEEE 1547 standard and the interface requirements of the local utility company. Some utility companies require PV inverters to have AC side grounding in order to assure compatibility with their grounding scheme, generally referred to as effective grounding.

Do inverters have a grounding point?

Some modern inverters are fitted with a grounding point connection in the inverter circuitry. Still, this grounding point must be disconnected when the inverter is connected to a power distribution panel with its grounding. The inverter must not be double grounded as this may cause a problem.

Which grounding rods are used in a solar inverter?

As shown in the fig, separate grounding rods are used for individual systems e.g. AC side and DC side. The equipment grounding conductor (EGC) from the main panel and PV arrays are connected to the Ground terminal and Ground bus in the inverter.

Do solar inverters need a ground wire?

The AC output terminals of the inverter supply the Neutral to Ground connection, and no secondary grounding connections are permitted. See also: Connect A Solar Panel To An Inverter (Here’s How) The ground fault detectors do not need a ground wire connection as they sense differential current between Hot and Neutral.

Guess what you want to know

-

Photovoltaic power high power inverter

Photovoltaic power high power inverter

-

How high are the bifacial solar panels from the ground

How high are the bifacial solar panels from the ground

-

How many photovoltaic strings are there in one inverter

How many photovoltaic strings are there in one inverter

-

How big an inverter should I use for a 170kw photovoltaic system

How big an inverter should I use for a 170kw photovoltaic system

-

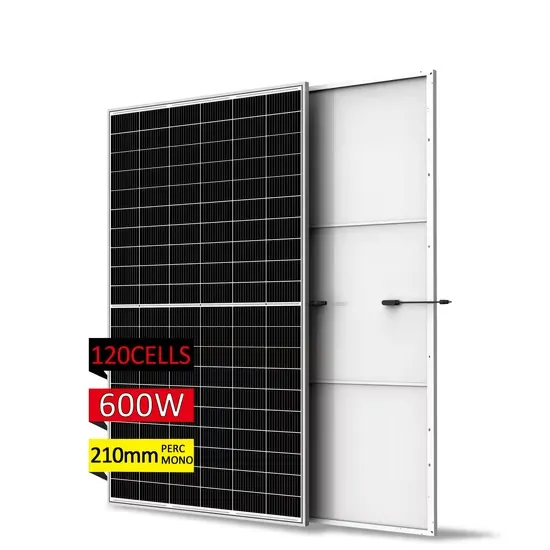

How big a solar panel does a 1kW photovoltaic inverter require

How big a solar panel does a 1kW photovoltaic inverter require

-

How much electricity can a 3kw photovoltaic inverter generate

How much electricity can a 3kw photovoltaic inverter generate

-

Photovoltaic inverter high frequency tolerance

Photovoltaic inverter high frequency tolerance

-

How much does a 6kw high frequency inverter cost

How much does a 6kw high frequency inverter cost

-

How much does a 4MW photovoltaic inverter cost

How much does a 4MW photovoltaic inverter cost

-

How much does a photovoltaic inverter cost

How much does a photovoltaic inverter cost

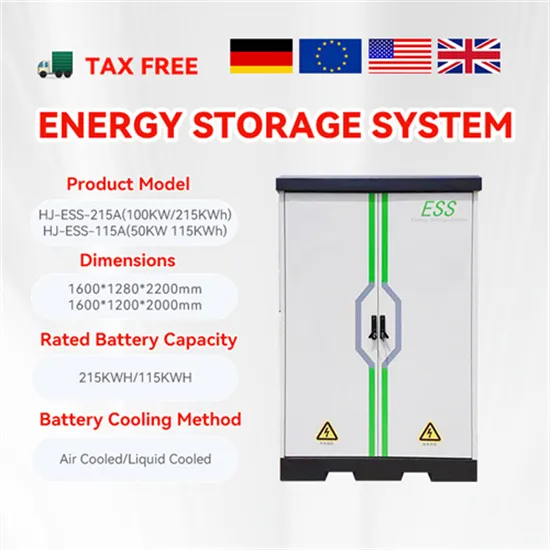

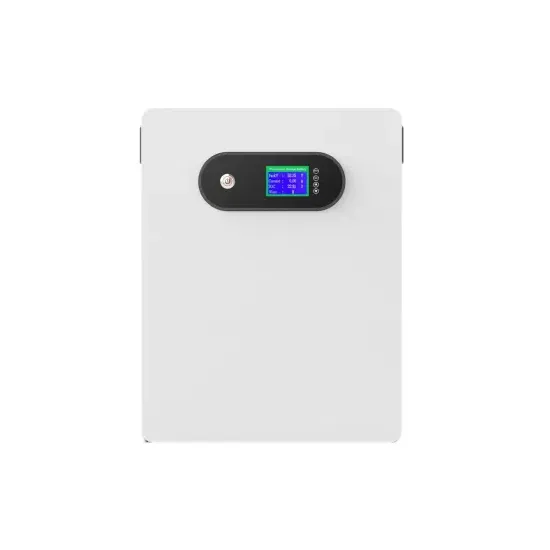

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.