Aluminum EV Battery Housing: Key Considerations for Enhanced

Using aluminum for battery housings can help dissipate heat effectively, mitigating overheating risks. Additionally, integrating features like heat sinks into the housing design can further

Get a quote

The Role of Aluminum Cathode Foil in Secondary

By conquering these obstacles, aluminum cathode foil can uphold its part in propelling battery technology forward and backing the shift toward

Get a quote

Materials for aluminum batteries: Progress and challenges

Aluminum battery technologies, including Al-air, Al-ion, and Al-sulfur (Al-S), are considered promising energy storage systems because of their high t

Get a quote

Aluminum batteries: Unique potentials and addressing key

Aluminum''s manageable reactivity, lightweight nature, and cost-effectiveness make it a strong contender for battery applications. Practical implementation of aluminum batteries

Get a quote

How Aluminum Material in EV Battery Cases Influence Range

One of the most significant advantages of using aluminum in EV battery cases is its contribution to enhancing the vehicle''s range. The lightweight nature of aluminum reduces the overall weight

Get a quote

The role of aluminum in electric vehicle manufacturing

Gina Cutts lists why aluminum''s unique properties, combined with advanced welding techniques, make it such an attractive option in electric

Get a quote

Aluminum-ion Battery

Aluminum-ion batteries represent a transformative leap in battery technology, offering rapid charging times, abundant raw material usage, and enhanced safety compared to

Get a quote

Powering the Future: How Aluminum is Revolutionizing Battery

In recent years, aluminum has emerged as a promising material for use in electric car batteries due to its many advantages. Not only is aluminum lightweight and abundant, but

Get a quote

Battery Cabinet Aluminum Frames | HuiJue Group E-Site

When designing modern battery cabinets, engineers face a critical question: How can we ensure decades of reliable service in harsh environments? The answer often lies in battery cabinet

Get a quote

The Critical Role of Battery...

🚗 The Critical Role of Battery Cooling Systems in EVs As electric vehicles (EVs) continue to surge in popularity, keeping their battery systems cool is more crucial than ever. Here''s why: Safety

Get a quote

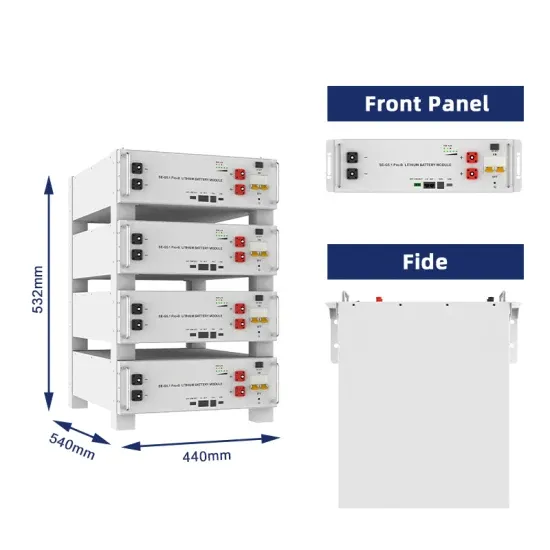

Battery Rack | External Battery Racks | Battery Cabinet

Explore the best battery racks and cabinets for power system reliability. Learn how they help store, organize and secure batteries in industrial, energy and backup systems.

Get a quote

How Aluminum Material in EV Battery Cases Influence

One of the most significant advantages of using aluminum in EV battery cases is its contribution to enhancing the vehicle''s range. The lightweight nature of

Get a quote

Constellium aluminum EV battery enclosures

Mass reduction is the main driver behind aluminum battery enclosures, but thermal requirements prove challenging for the lightweight material. Aluminum is the dominant material

Get a quote

Li-Ion Battery Cabinets

CellBlock cabinets are a superior solution for the safe storage of lithium-ion batteries and devices containing them. This robust cabinet is manufactured from aluminum and lined with CellBlock''s

Get a quote

Battery and Energy Storage

Battery Boxes, Cabinets and Enclosures of All Shapes and Sizes Fabricated Metals manufactures indoor and outdoor industrial enclosures to meet the needs of the Battery + Energy Storage

Get a quote

Aluminum Profiles in Lightweight Electric Vehicle (EV)

In this article, we will explore the unique benefits of aluminum profiles in EV battery housing designs, focusing on their structural, thermal,

Get a quote

The Future of Aluminum in Battery Technology:

This article delves deep into the future of aluminum in battery technology, exploring how it enhances efficiency and longevity in electric

Get a quote

The Growing Role of Aluminum Slugs in Battery and Capacitor

Aluminum slugs are becoming increasingly important in the production of battery shells and capacitor housings, driven by rapid advancements in electronics, electric vehicles, and energy

Get a quote

Aluminum Components in Electrical and Electronic

Heat Sinks The role of heat sinks in electronic systems cannot be overstated. Effective heat dissipation is crucial for maintaining the

Get a quote

6061-T6 Battery Box Aluminum Profiles: Applications and

In automotive production, aluminum trays and battery enclosures are pivotal components. Among these, 6061-T6 battery box aluminum profiles stand out as the industry''s

Get a quote

Aluminum In Lithium-Ion Batteries: Enhancing Performance And

Aluminum also serves as a favorable material for battery casings and current collectors due to its strength and durability. The integration of aluminum in lithium-ion batteries

Get a quote

Aluminum Profiles in Lightweight Electric Vehicle (EV) Battery

In this article, we will explore the unique benefits of aluminum profiles in EV battery housing designs, focusing on their structural, thermal, and sustainability advantages.

Get a quote

The Future of Aluminum in Battery Technology: Enhancing

This article delves deep into the future of aluminum in battery technology, exploring how it enhances efficiency and longevity in electric vehicles and portable electronics.

Get a quote

Complete Guide for Battery Enclosure

Extrusion plays an integral role in the battery box enclosure manufacturing process. Currently, many EV manufacturers are adopting aluminum extrusion for battery casing.

Get a quote

EV battery case – definition and material analysis

EV battery case material Steel plates, aluminum plates, extruded aluminum, die-cast aluminum, glass fiber composites, SMC composites, and carbon fiber composites are all used.

Get a quote

Guess what you want to know

-

The role of battery cabinets in households

The role of battery cabinets in households

-

The role of aluminum acid battery inverter

The role of aluminum acid battery inverter

-

The role of battery energy storage cabinets

The role of battery energy storage cabinets

-

Various new energy battery cabinets

Various new energy battery cabinets

-

What kind of battery cabinets are more common in Mexico

What kind of battery cabinets are more common in Mexico

-

Which manufacturer should I look for for Seychelles outdoor communication battery cabinets

Which manufacturer should I look for for Seychelles outdoor communication battery cabinets

-

Where to produce outdoor communication battery cabinets in Equatorial Guinea

Where to produce outdoor communication battery cabinets in Equatorial Guinea

-

Which battery cabinets are most common in Eastern Europe

Which battery cabinets are most common in Eastern Europe

-

Where can I buy battery cabinets in Zambia

Where can I buy battery cabinets in Zambia

-

How many battery cabinets are needed for a DC panel

How many battery cabinets are needed for a DC panel

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.