Key Components of DC Fast Charging Stations

People new to the Electric Vehicle (EV) industry may find the DC fast charging ecosystem complex. Let''s examine the equipment and utility infrastructure required for DC fast

Get a quote

Sizing of 110V DC charger for MV panels – Auxiliary power

An auxiliary DC power system that consists of a charger, battery bank, DC distribution system, and monitoring system is a critical part of the primary/secondary substation.

Get a quote

Substation Battery Sizing Calculation Made Easy

Now let''s take a peek at a low voltage power schematic with a DC panel. This schematic is similar to the previous one, but now the battery charger feeds a 125V DC panel

Get a quote

Battery Room Design Requirements – PAKTECHPOINT

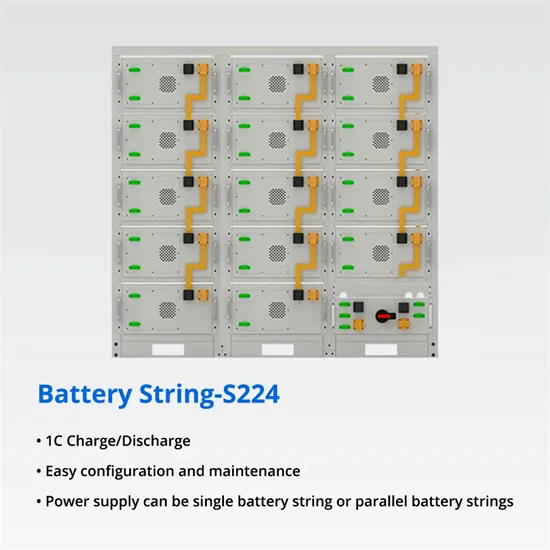

Generally, a single power cabinet can be connected to up to four charging dispensers. Power can be modulated via a load management system

Get a quote

Battery Enclosures & Cabinets

Most industrial off-grid solar power sytems, such as those used in the oil & gas patch and in traffic control systems, use a battery or multiple batteries that need a place to live, sheltered from the

Get a quote

Sizing of 110V DC charger for MV panels

Through this article, the readers can get an idea to design and put together a complete 110V auxiliary DC supply system for a typical MV power

Get a quote

Sizing DC Systems for Switchgears

Function: Batteries play a crucial role in providing DC power to switchgear equipment during outages, ensuring uninterrupted operation and protecting critical loads.

Get a quote

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

If a fan is not required, 1" of space per side is acceptable, so a 48"L cabinet could work. For the depth, factor in 1" of extra space for the front and back or 2" total.

Get a quote

How many batteries can the energy storage cabinet store?

The type of battery technology employed greatly impacts how many batteries can be incorporated into an energy storage cabinet. Different battery technologies have distinct

Get a quote

What Size Solar Panel Do I Need to Charge a 12v

How many solar panels you need to charge a 12v battery? Calculating the number of solar panels for your 12V battery depends on understanding your

Get a quote

3 Types of DCFC Site Architecture

Generally, a single power cabinet can be connected to up to four charging dispensers. Power can be modulated via a load management system to each of the four

Get a quote

Solar power storage: How many batteries do you need?

How many solar batteries do I need for my house? Finding the number of solar batteries you need for your home is not a one-size-fits-all

Get a quote

How much solar power do I need to run a refrigerator:

To run a refrigerator on solar power, you would need a solar energy system that consists of: Solar panels: To produce the amount of

Get a quote

How many batteries can the energy storage cabinet

The type of battery technology employed greatly impacts how many batteries can be incorporated into an energy storage cabinet. Different

Get a quote

How to Right-Size Your Battery Storage System

An off-grid system with solar, however, relies solely on battery storage to power your home when solar isn''t producing power, making proper battery sizing

Get a quote

Solar Panel Amps Calculator (Watts to Amps) – Dot Watts®

Solar panel output: Enter the total capacity of your solar panel (Watts). Vmp: Is the operating voltage of the solar panel which you can check at the back side of your solar panel.

Get a quote

Battery Cabinets vs. Battery Racks

Additional cooling is rarely required for a battery cabinet, but the cabinet must have (1) unobstructed paths within the cabinet for hot air to rise, and (2) adequate openings for

Get a quote

Battery Cabinets vs. Battery Racks

UPS systems frequently operate at high dc voltages (e.g., 250 to 800 Volts). An analysis must be made on whether to have a minimum number of battery strings using

Get a quote

Substation Battery Sizing Calculation Made Easy

Now let''s take a peek at a low voltage power schematic with a DC panel. This schematic is similar to the previous one, but now the battery

Get a quote

How Many Watt Solar Panel to Charge 12 Volt Battery: Calculate

Unlock the power of solar energy with our comprehensive guide on how many watts are needed to charge a 12-volt battery. Learn about different solar panel types, key

Get a quote

Battery Room Design Requirements – PAKTECHPOINT

This is about design requirements for vented lead acid batteries, battery rooms and battery installations in main and unit substations and electrical equipment rooms.

Get a quote

Sizing of 110V DC charger for MV panels – Auxiliary

An auxiliary DC power system that consists of a charger, battery bank, DC distribution system, and monitoring system is a critical part of the

Get a quote

UPS Battery Cabinet Upgrade, Retrofit, Replacement

Explore the different VRLA and Lithium Ion battery cabinets that are compatible with Mitsubishi Electric''s various uninterruptible power supply systems, as well as the batteries each cabinet

Get a quote

Battery Cabinet

This manual contains information on Atlantic Battery Systems battery cabinets. The information in this manual is intended for Qualified Installers, Equipment Engineers, and Field Support

Get a quote

6 FAQs about [How many battery cabinets are needed for a DC panel ]

How many cells can a battery cabinet hold?

One cabinet should be able to hold at least one complete string of cells. Best practice is that strings should not be split between two cabinets in order to ensure reliability of the entire string. Figure 1 - Battery cabinet with top terminal cells

Do battery cabinets have top clearance?

Battery cabinets are frequently criticized for their lack of top clearance. For example, in a cabinet containing multiple strings of low ampere-hour batteries, there might be several shelves, each with one string of cells. The cell units on each shelf might be arranged two, three, or more cells deep.

Should UPS batteries be installed on racks or in cabinets?

Early on in a UPS design a decision must be made on whether batteries should be installed on racks or in cabinets. Both have pros and cons. The following are typical design considerations.

Why do you need a battery cabinet?

Ease of use is one of the principle selling points for battery cabinets. It is convenient to service the equipment when the UPS and the battery (ies) are right next to each other. Conversely, it is inconvenient to have to go to a separate room when open-rack batteries are installed.

Does a battery room cover maintenance free or computer room type batteries?

It does not cover maintenance free or computer room type batteries and battery cabinets. Main keywords for this article are Battery Room Design Requirements, vented lead acid batteries, battery room safety requirements, Battery Room Ventilation, unit substations electrical. Batteries can be hazardous to both personnel and equipment.

Can you put a battery in an electrical room?

Local or regional codes may dictate whether batteries are permitted in an electrical room. Smaller UPS systems (e.g, up to 250 kVA) are commonly installed directly in the computer room along with their respective battery cabinets. The UPS and/or battery cabinets might be configured to look like standard computer equipment racks.

Guess what you want to know

-

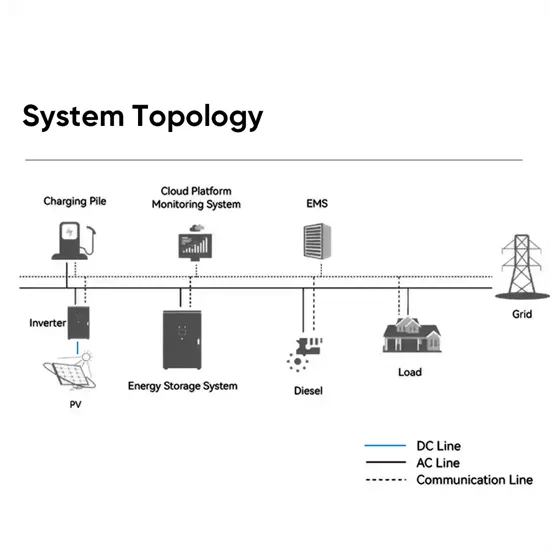

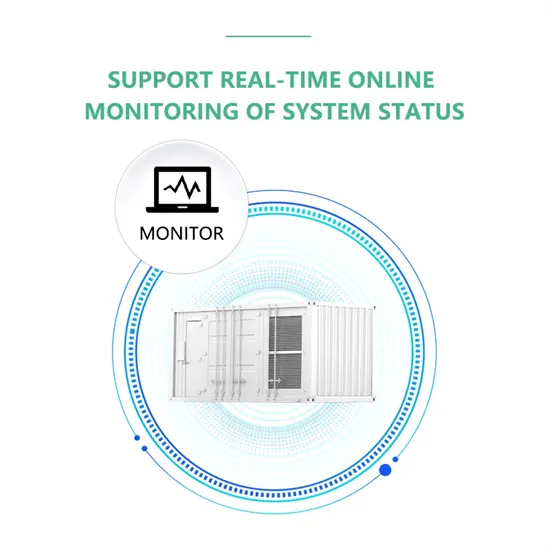

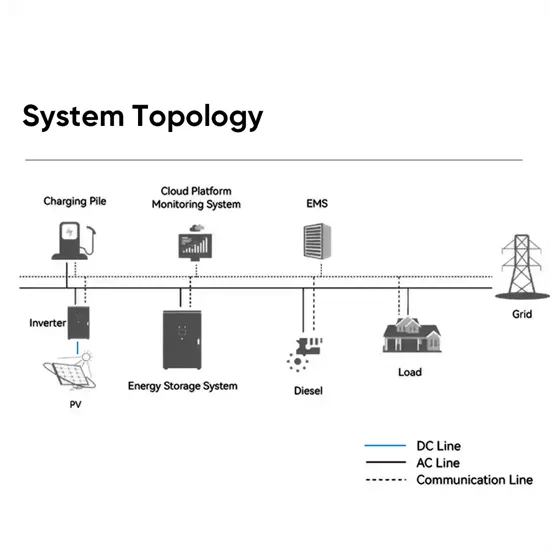

How to use DC battery cabinets for energy storage

How to use DC battery cabinets for energy storage

-

How many volts of battery are needed for an 81v photovoltaic panel

How many volts of battery are needed for an 81v photovoltaic panel

-

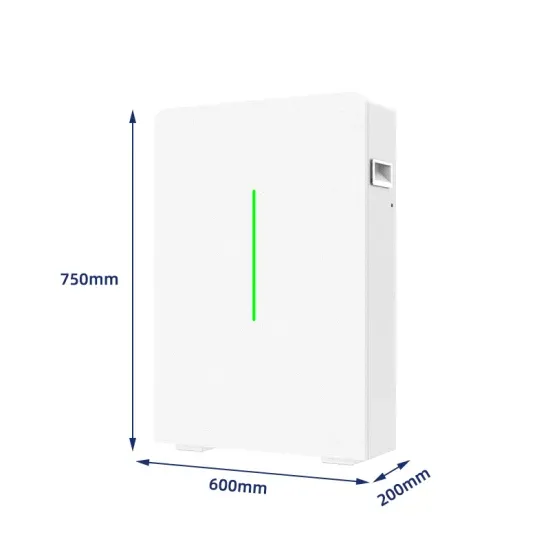

How big is the DC panel battery cabinet

How big is the DC panel battery cabinet

-

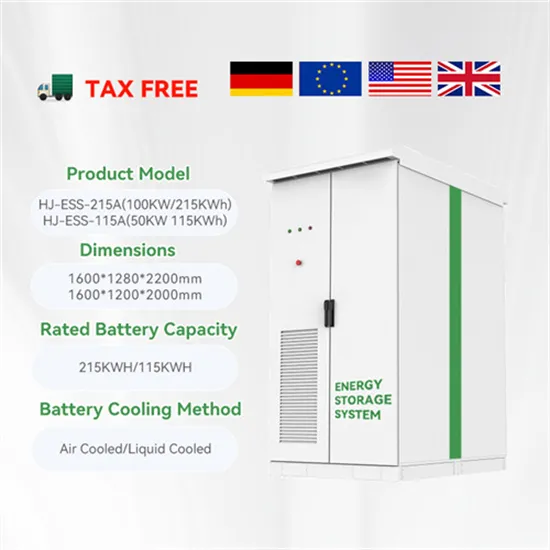

How many liquid-cooled energy storage battery cabinets are there in Germany

How many liquid-cooled energy storage battery cabinets are there in Germany

-

How to connect two battery cabinets in parallel

How to connect two battery cabinets in parallel

-

How Large a Battery Can a 6V 30W Solar Panel

How Large a Battery Can a 6V 30W Solar Panel

-

How many watts of photovoltaic panels are needed to charge a 12v battery

How many watts of photovoltaic panels are needed to charge a 12v battery

-

How big a solar panel is needed for 1gw

How big a solar panel is needed for 1gw

-

How many watts are needed for a civilian solar panel

How many watts are needed for a civilian solar panel

-

How big a battery can a 440w photovoltaic panel charge

How big a battery can a 440w photovoltaic panel charge

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.