Motor Drive Efficiency and Loss at High Frequencies

Advancements in silicon and wide-bandgap (WBG) semiconductors have revolutionized power converters, allowing inverters to operate at frequencies up to several

Get a quote

Power Frequency Inverter vs. High Frequency

Efficiency and energy consumption: Because frequency drive inverters use high-frequency switching technology, their switching losses and

Get a quote

Low Frequency vs High Frequency Inverters: Which One Is Best?

There are two main types of frequencies to be compared: low frequency vs high frequency inverters. The inverter frequency determines the desired application''s compatibility, efficiency,

Get a quote

Mastering Inverter Switching Frequencies: A

Explore the intricate dance of inverter switching frequencies to optimize energy flow. Master the rhythms of power electronics with our

Get a quote

Towards Energy Efficiency: Innovations in High

This study reviews advancements in high-frequency converters for renewable energy systems and electric vehicles, emphasizing their role in

Get a quote

Low Frequency vs High Frequency Inverters: Which

There are two main types of frequencies to be compared: low frequency vs high frequency inverters. The inverter frequency determines the desired

Get a quote

Inverter | Efficiency & Output Waveform

The article provides an overview of inverters in renewable energy systems, focusing on their role in converting DC to AC, their efficiency, and

Get a quote

Maximizing Efficiency with 48V Low Frequency Inverters: A

Conclusion: Harness the Power of 48V Low Frequency Inverters for Unmatched Efficiency Unlock the potential of 48V low frequency inverters and experience unparalleled efficiency,

Get a quote

Efficiency of the inverter

efficiency of the inverter is defined as the ratio between the power output at the AC side and the power input at the DC side. This definition comprises the complete inverter unit. Since the real

Get a quote

Comparing High-Frequency vs. Low-Frequency Inverters

When selecting an inverter, two key factors to consider are its operating frequency and efficiency. This article will compare high-frequency and low

Get a quote

Understanding inverter frequency – effects and adjustments

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical implications.

Get a quote

Comparing High-Frequency vs. Low-Frequency Inverters

When selecting an inverter, two key factors to consider are its operating frequency and efficiency. This article will compare high-frequency and low-frequency inverters, examining their

Get a quote

Efficiency and Power Loss Distribution in a High

The paper presents efficiency and power loss analysis in a high-frequency, seven-level diode-clamped inverter (7LDCB). The inverter is

Get a quote

6.5. Efficiency of Inverters | EME 812: Utility Solar Power and

The efficiency of an inverter indicates how much DC power is converted to AC power. Some of the power can be lost as heat, and also some stand-by power is consumed for keeping the

Get a quote

PWM Inverter Power Measurement System Required for Evaluating

Measuring power accurately in the inverter switching frequency and its harmonic frequency domain is critical in order to properly evaluate the performance of high efficiency

Get a quote

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get a quote

Optimizing power efficiency and density in power electronics

Power electronics designers are striving to increase power efficiency and power density in industrial and automotive designs ranging from multiaxis drives to solar energy storage to

Get a quote

Motor Drive Efficiency and Loss at High Frequencies

Studying high switching frequency in motor drive systems offers valuable insights into efficiency and loss characteristics. Advancements in

Get a quote

Efficiency of Inverter: Calculation & Equation Guide

The efficiency of an inverter refers to the amount of AC output power it provides for a given DC input. This normally falls between 85 and 95 percent, with 90 percent being the average.

Get a quote

(PDF) Analysis Of Development of Traction Inverters and Control

A comparison of multilevel inverters with their two-level counterpart is conducted in terms of efficiency, cost, power density, power quality, reliability, and fault tolerance.

Get a quote

Guide to Frequency Inverters: Optimizing Motor Performance, Efficiency

Frequency inverters, also known as variable frequency drives (VFDs), are essential components in modern motor control systems. These devices convert fixed

Get a quote

Experimental Tests and Simulations About The Efficiency of

To this aim, the inverter manufacturers have introduced the possibility for residential inverters to set the power factor. These new capabilities have been exploited in this paper in

Get a quote

Power Frequency Inverter vs. High Frequency Inverter: Which is

Efficiency and energy consumption: Because frequency drive inverters use high-frequency switching technology, their switching losses and iron losses are relatively small, so

Get a quote

Low Vs High Frequency Inverters/UPS Comparison

Learn the key differences between high frequency inverters and low frequency inverters. Discover which one suits your power needs for efficiency and surge capacity.

Get a quote

Design and Development of High Frequency Inverter for

Overall, implementing a high-frequency inverter for WPT applications requires careful consideration of several factors, including power requirements, efficiency, and EMI.The

Get a quote

Guide to Frequency Inverters: Optimizing Motor

Frequency inverters, also known as variable frequency drives (VFDs), are essential components in modern motor control systems. These

Get a quote

Mastering Inverter Switching Frequencies: A Comprehensive Guide

Explore the intricate dance of inverter switching frequencies to optimize energy flow. Master the rhythms of power electronics with our comprehensive guide, your blueprint to

Get a quote

Power Frequency Inverter vs High-Frequency Inverter

High-frequency inverters are typically more efficient at converting power while maintaining a constant load for lighter loads, which is significant when you depend on battery

Get a quote

Guess what you want to know

-

Which energy storage inverter is better power frequency or high frequency

Which energy storage inverter is better power frequency or high frequency

-

Cambodia high frequency power inverter

Cambodia high frequency power inverter

-

Qatar three-phase power frequency inverter

Qatar three-phase power frequency inverter

-

Photovoltaic power frequency inverter and pure sine wave inverter

Photovoltaic power frequency inverter and pure sine wave inverter

-

Uruguay off-grid power frequency 15kw inverter

Uruguay off-grid power frequency 15kw inverter

-

Austria power frequency off-grid inverter

Austria power frequency off-grid inverter

-

Photovoltaic inverter power frequency withstand voltage

Photovoltaic inverter power frequency withstand voltage

-

High-power photovoltaic power frequency inverter

High-power photovoltaic power frequency inverter

-

Power frequency inverter sine wave

Power frequency inverter sine wave

-

Israel three-phase power frequency inverter

Israel three-phase power frequency inverter

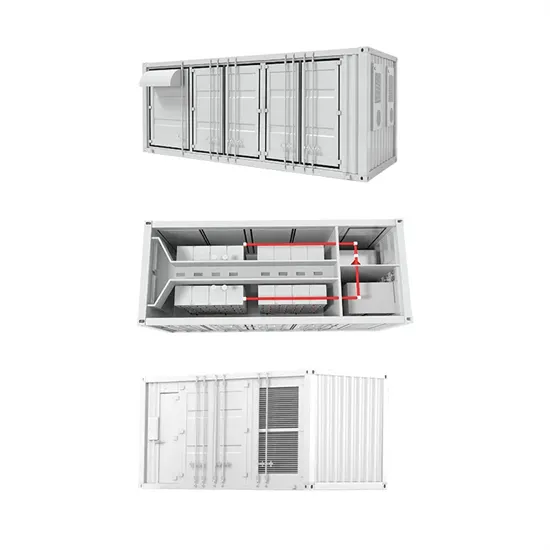

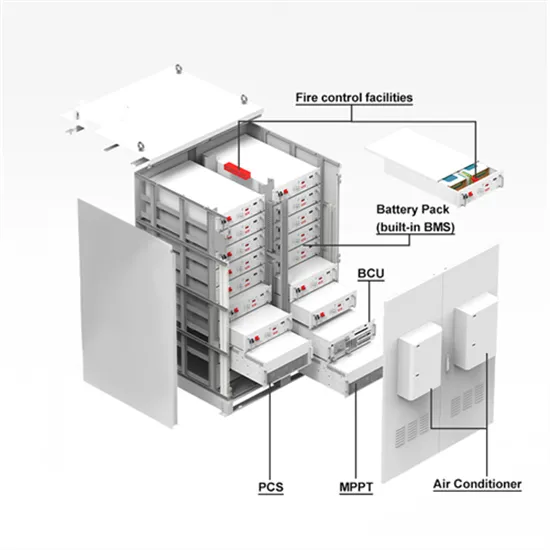

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.