Lithium battery with an unsupported Inverter

What DC voltage are you planning, what parameters can you access and change on your inverter. Two gel batteries could be 12 Volts or 24 volts. A lot depends on how much

Get a quote

Can a 48V Inverter Work with a 24V Battery?

No, a 48V inverter cannot work directly with a 24V battery without additional modifications. The key reason for this is the difference in voltage. Inverters are designed to

Get a quote

Can You Mix Different Capacity Lithium Batteries?

Schematic for multiple lithium batteries in parallel Here is a diagram for multiple lithium batteries in parallel. You can add individual battery

Get a quote

Microsoft Word

The following V28TM POWER Lithium-Ion Charger & Battery Pack Troubleshooting Guide used in conjunction with a ''new-from-stock known good'' 48-11-2830 28V Lithium-Ion Battery Pack and

Get a quote

How to Safely Connect a Battery to an Inverter: A

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend

Get a quote

Can I Attach My Small Inverter Directly to the Battery?

Yes, you can attach a small inverter directly to a battery, but doing it safely requires understanding voltage compatibility, wire sizing, and overload risks. Many DIYers assume it''s

Get a quote

Can a 24V inverter be installed on a 7-string 28v lithium battery

In this example, we will consider a 7S lithium-ion battery running a 24-volt AC inverter. A 7S lithium-ion battery has a fully charged voltage of 29.4 volts and a dead voltage of about 18.5

Get a quote

is it safe that my 24 volt battery output 28.8 volt

24V is the nominal voltage, which is not the same as the charging voltage. In your case 28.8V (14.4V for a 12V battery) is the Absorption voltage. Depending on your battery type

Get a quote

How to connect inverter to battery: a step-by-step guide for safe

Below, we''ll explore how to connect inverter to battery, its purpose, and the tools needed for a proper and safe connection. Learning how to connect inverter to battery serves a

Get a quote

How to connect inverter to battery: a step-by-step

Below, we''ll explore how to connect inverter to battery, its purpose, and the tools needed for a proper and safe connection. Learning how

Get a quote

Can a 24V inverter be installed on a 7-string 28v lithium battery pack

In this example, we will consider a 7S lithium-ion battery running a 24-volt AC inverter. A 7S lithium-ion battery has a fully charged voltage of 29.4 volts and a dead voltage of about 18.5

Get a quote

12V vs. 24V Battery Systems: How They Differ and Which to

In contrast, a 24V system can be achieved in two ways: by purchasing a dedicated 24V battery or by connecting two 12V batteries in series, effectively doubling the voltage to 24

Get a quote

How to Safely Connect a Battery to an Inverter: A Step-by-Step

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend system life.

Get a quote

Connecting Multiple Batteries to an Inverter: Easy Guide

You would end up inputting 24V to the inverter and cause an overload. This could cause damage to your equipment, at the very least your inverter will shut down to protect itself.

Get a quote

Growatt 24V 3k Inverter and Lithium Battery wiring diagram and

Growatt 24V 3k Inverter and Lithium Battery wiring diagram and installation video 2021-11-17 Go to download Wildman13 Nov 17, 2021

Get a quote

When to Use a 24V or 48V Battery System Instead of a 12V System

So for a 12V battery power system with a cable of 8 AWG, we do not want to exceed 480W. Above 480W, we want to increase the battery voltage our system uses, so that we can

Get a quote

Connecting Multiple Batteries to an Inverter: Easy Guide

You would end up inputting 24V to the inverter and cause an overload. This could cause damage to your equipment, at the very least your inverter will shut

Get a quote

Calculate Battery Size For Any Size Inverter (Using Our Calculator)

Yes, you can attach a small inverter directly to a battery, but doing it safely requires understanding voltage compatibility, wire sizing, and overload risks. Many DIYers assume it''s

Get a quote

Amazon : 28 Volt Battery Charger

28.8 Volt Battery Charger for Ride On Toys 28.8V800mA Kids Ride On Car Charger for Best Choice Products Wrangler SUV Kid Trax Dynacraft Toy Car Charger baby electric Battery

Get a quote

What Size Inverter Can I Run Off a 100Ah Battery? A

Understanding Battery and Inverter Basics Battery Capacity and Inverter Compatibility A 100Ah battery signifies its capacity to deliver 100 ampere-hours of current. This

Get a quote

How to Connect an Inverter to a Battery: Step-by-Step Guide for

Properly connecting your inverter to a battery is essential for a reliable and efficient power backup system. By following the steps outlined in this guide, you can ensure a safe and seamless setup.

Get a quote

Lithium Batteries: What Size Inverter Can I Use?

Bottom line, if you want to run large inverter loads above 1000w on a lithium battery, make sure you choose an lithium battery that is designed for larger inverters or a system that can be

Get a quote

Compatibility of Lithium-Ion Batteries with Existing Inverters

While it''s possible to install a lithium-ion battery yourself, it''s highly recommended to work with a professional to ensure safety and proper integration with your existing inverter.

Get a quote

28V Forward Facing Sonar Converter

This unit is only for the black boxes and cannot be used on head units. This unit is designed to run off of existing 24v and 36v volt trolling systems in the boat and steps the current down or up to

Get a quote

Lithium Batteries: What Size Inverter Can I Use?

Bottom line, if you want to run large inverter loads above 1000w on a lithium battery, make sure you choose an lithium battery that is designed for larger

Get a quote

How to Connect an Inverter to a Battery: Step-by-Step

Properly connecting your inverter to a battery is essential for a reliable and efficient power backup system. By following the steps outlined in this guide,

Get a quote

Lithium battery with an unsupported Inverter

What DC voltage are you planning, what parameters can you access and change on your inverter. The inverter require 24V. I can change things like overload bypass, bulk

Get a quote

The Ultimate Guide to 24V Lithium Ion Battery Packs

In the world of portable power solutions, 24V lithium ion battery packs have emerged as versatile champions, catering to a myriad of applications from electric bikes to industrial

Get a quote

Calculate Battery Size For Any Size Inverter (Using Our Calculator)

You would need around 24v 150Ah Lithium or 24v 300Ah Lead-acid Battery to run a 3000-watt inverter for 1 hour at its full capacity. Here''s a battery size chart for any size inverter

Get a quote

6 FAQs about [Can a 24V inverter be installed on a 7-string 28V lithium battery pack in Bhutan ]

Do inverters and batteries need to match?

The inverter and batteries must match in terms of voltage, capacity, and power output. If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment.

Are all inverters compatible with lithium-ion batteries?

These include the inverter’s voltage, charging algorithm, and overall compatibility with lithium-ion technology. Not all inverters are created equal. Some may be specifically designed for traditional batteries, while others can seamlessly integrate with lithium-ion batteries. Check your inverter’s specifications to ensure compatibility.

Why do lithium batteries need inverters?

With today’s lithium batteries, inverters play a big part due to the energy that a lithium battery can deliver. For lithium batteries that run external BMS systems, the output current restrictions are much less compared to a lithium battery with an internal BMS system.

Can a 12V inverter be connected to a 24v battery?

Let’s say you have a 12V inverter and try to connect two 12V batteries in series. You would end up inputting 24V to the inverter and cause an overload. This could cause damage to your equipment, at the very least your inverter will shut down to protect itself.

Should Inverter Batteries be wired in series?

If you decide to wire your inverter batteries in series it will increase the voltage and limit how many you can hook up to your inverter. Many people prefer to connect batteries and inverters in parallel. This is because there is less limitation on how many batteries you can connect to your inverter at once.

Can you add more batteries to an inverter?

To add more batteries to an inverter you need to check how your equipment is connected. You should assess whether the batteries are wired in series or parallel. If they are wired in series, you won’t be able to add more batteries as the voltage will increase rather than the battery capacity.

Guess what you want to know

-

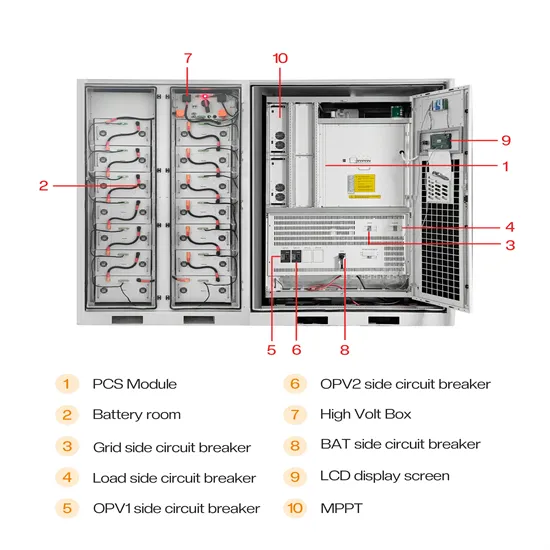

Inverter and lithium battery installed together

Inverter and lithium battery installed together

-

What is the volume of a 24v 12A lithium battery pack

What is the volume of a 24v 12A lithium battery pack

-

6 series 4 parallel 24v lithium battery pack

6 series 4 parallel 24v lithium battery pack

-

28v lithium battery pack usage

28v lithium battery pack usage

-

Reference price of good lithium battery pack in Croatia

Reference price of good lithium battery pack in Croatia

-

Multi-level current protection method for lithium battery pack

Multi-level current protection method for lithium battery pack

-

Romanian lithium iron phosphate battery pack

Romanian lithium iron phosphate battery pack

-

48v 100ah lithium iron phosphate battery pack

48v 100ah lithium iron phosphate battery pack

-

Syria wide temperature lithium titanate battery pack

Syria wide temperature lithium titanate battery pack

-

17 lithium battery pack

17 lithium battery pack

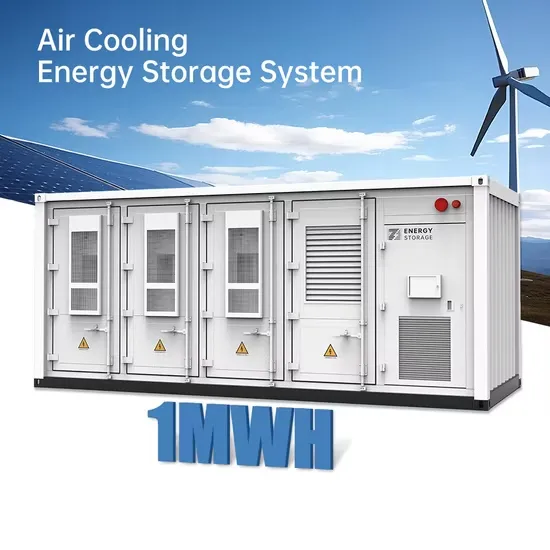

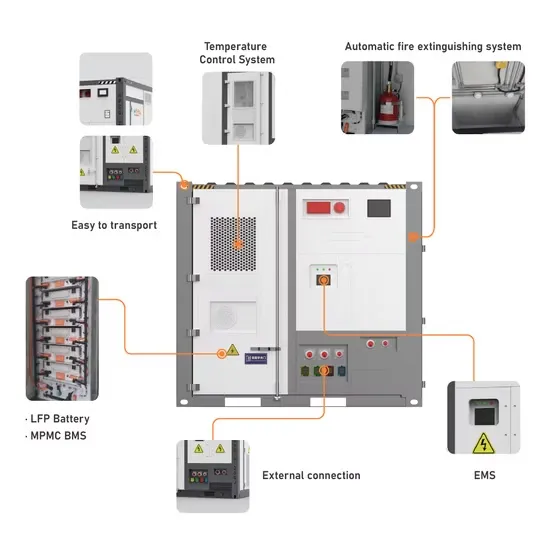

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

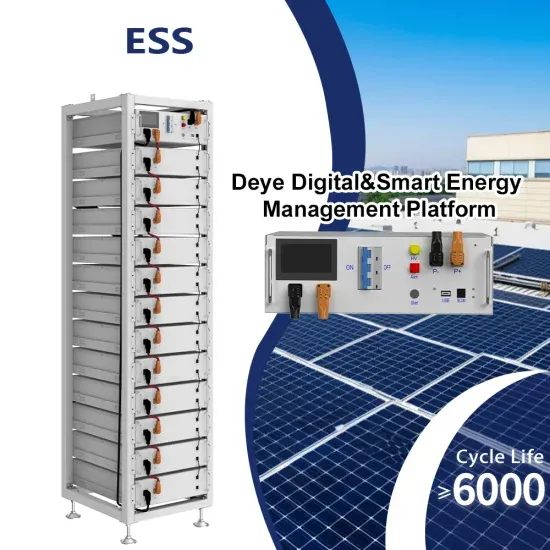

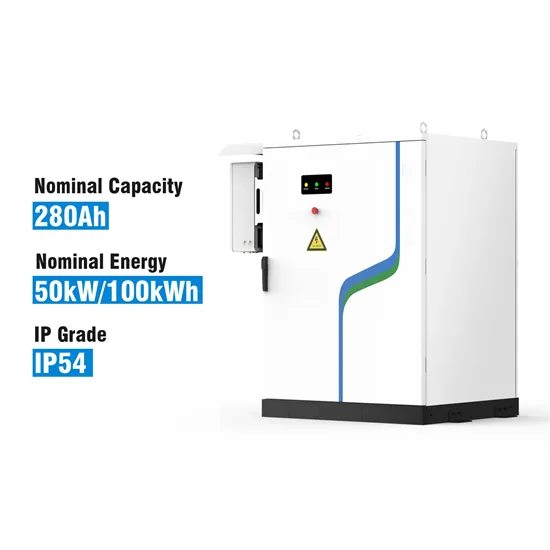

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.