Modeling and Simulation of Single Flow Zinc–Nickel Redox

In this study, we established a comprehensive two-dimensional model for single-flow zinc–nickel redox batteries to investigate electrode reactions, current-potential behaviors,

Get a quote

Study on Ion Transport Mechanism of Zinc-Nickel Single-Flow Battery

Abstract Since the microstructure of porous electrode is very important to the performance of zinc-nickel single-flow battery, this paper reconstructed the microstructure of

Get a quote

Zinc dendrite removal in a nickel-zinc battery with flow-through

A schematic representation of the prototype battery setup with flow-through electrodes. The anode zinc electrodes are shown in purple and the cathode nickel

Get a quote

Zn-Nickel Flow Battery Electrode

Preliminary study of single flow zinc–nickel battery Based on full consideration about characteristics of the zinc/nickel battery and single flow lead/acid battery, we proposed a

Get a quote

Inhibition of Zinc Dendrites in Zinc-Based Flow

Some of these flow batteries, like the zinc-bromine flow battery, zinc-nickel flow battery, zinc-air flow battery, and zinc-iron battery, are already in the

Get a quote

Designing interphases for practical aqueous zinc flow

We investigated artificial interphases created using a simple electrospray methodology as a strategy for addressing each of these challenges.

Get a quote

Zinc–Nickel Single Flow Battery | 10 | Redox Flow Batteries

The zinc–nickel single flow battery (ZNB) is a promising energy storage device for improving the reliability and overall use of renewable energies because of its advantages: a simple structure

Get a quote

Boosting ultra-long cycling and shelf life of nickel−zinc battery

Alkaline nickel−zinc (Ni−Zn) battery has been considered as a competitive candidate for the application of uninterrupted power supply and grid energy storage due to the

Get a quote

Study of zinc electrodes for single flow zinc/nickel battery

Combining conventional zinc–nickel battery with the single flow lead-acid battery, another single electrolyte system, a single flow Zn–Ni battery system, has been proposed by

Get a quote

Study of zinc electrodes for single flow zinc/nickel battery

In order to demonstrate the effect of cadmium-plated electrode and flowing electrolyte on the capacity and cycle life of the single flow zinc/nickel cell, a number of

Get a quote

Zinc dendrite removal in a nickel-zinc battery with flow-through electrodes

A schematic representation of the prototype battery setup with flow-through electrodes. The anode zinc electrodes are shown in purple and the cathode nickel

Get a quote

High-energy and high-power Zn–Ni flow batteries with semi-solid electrodes

In this work, we show how combining high power density and low-yield stress electrodes can minimize energy loss due to pumping, and have demonstrate methods to achieve high energy

Get a quote

High-voltage and dendrite-free zinc-iodine flow battery

Herein, we propose a chelated Zn (P2O7)26- (donated as Zn (PPi)26-) negolyte, which facilitates dendrite-free Zn plating and effectively

Get a quote

High-voltage and dendrite-free zinc-iodine flow battery

Herein, we propose a chelated Zn (P2O7)26- (donated as Zn (PPi)26-) negolyte, which facilitates dendrite-free Zn plating and effectively prevents Zn2+ crossover.

Get a quote

Analysis of internal reaction and mass transfer of zinc

A three-dimensional steady state model of internal reaction and mass transfer has been established for a better understanding of

Get a quote

Zinc Electrode Morphology Evolution in High Energy Density Nickel

Prismatic Nickel-Zinc (NiZn) batteries with energy densities higher than 100 Wh kg −1 were prepared using Zn electrodes with different initial morphologies. The effect of initial

Get a quote

The characteristics and performance of hybrid redox flow batteries

The benefits and limitations of zinc negative electrodes are outlined with examples to discuss their thermodynamic and kinetic characteristics along with their practical aspects. Four

Get a quote

Structural Modification of Negative Electrode for Zinc–Nickel

The accuracy of the simulation model is verified by experiments, and then the polarization distribution in a zinc-nickel single-flow battery with nickel-plated steel strip (NS) as

Get a quote

Designing interphases for practical aqueous zinc flow batteries

We investigated artificial interphases created using a simple electrospray methodology as a strategy for addressing each of these challenges.

Get a quote

A high power density single flow zinc–nickel battery with three

Low power density (operated current density) is one critical obstacle to the development of single flow zinc–nickel batteries (ZNBs). Three-dimensional porous nickel

Get a quote

Electrodeposited Zinc Alloy Anodes for Aqueous Zinc Metal

4 days ago· The application of aqueous zinc metal batteries (AZMBs) is hindered by uncontrollable plating/stripping and side reactions during the deep cycling of zinc (Zn) foil

Get a quote

High-voltage and dendrite-free zinc-iodine flow battery

Researchers reported a 1.6 V dendrite-free zinc-iodine flow battery using a chelated Zn(PPi)26- negolyte. The battery demonstrated stable

Get a quote

Electrodeposited Zinc Alloy Anodes for Aqueous Zinc Metal Batteries

4 days ago· The application of aqueous zinc metal batteries (AZMBs) is hindered by uncontrollable plating/stripping and side reactions during the deep cycling of zinc (Zn) foil

Get a quote

Modeling and Simulation of Single Flow Zinc–Nickel Redox Battery

In this study, we established a comprehensive two-dimensional model for single-flow zinc–nickel redox batteries to investigate electrode reactions, current-potential behaviors,

Get a quote

US9379373B2

A nickel-zinc battery includes a battery housing, a nickel oxide positive electrode supported in the battery housing, a metal substrate negative electrode supported in the battery housing, a

Get a quote

Nickel Zinc Flow Battery Nic

Nickel-Zinc System ADVANTAGES AVAILABLE ABUNDANT MATERIALS LOW COST MATERIALS, THEORETICALLY $32.2/KWHR (Based on current metals price, Ni: $11/lbs, Zn:

Get a quote

6 FAQs about [Zn-Nickel Flow Battery Electrode]

How is zinc deposited in a single flow battery?

Comparatively, in the case of single flow zinc–nickel batteries, the zinc should be deposited on an inert substrate and dissolved into the solution, alternately. As a result, the nature of the substrate has great effect on the reaction process and the deposition morphology of the zinc.

What is a Zn Ni semi-solid flow battery?

When compared with other aqueous systems, the Zn–Ni semi-solid flow battery system developed here has promising energy and power densities. This newly-designed aqueous Zn–Ni semi-solid flow battery paves a way to develop environmentally friendly and cost-effective energy storage systems for stationary applications.

What are ZnO and Ni (OH) 2 flowable electrodes?

We have developed ZnO and Ni (OH) 2 flowable electrodes with high power and energy densities and negligible energy loss during pumping for Zn–Ni semi-solid flow battery (SSFB), by combining both electrochemistry knowledge and understanding of the rheology of semi-solid electrodes (a high-volume fraction suspension).

Why does a single flow Zn/Ni battery have different substrates?

But, in the single flow Zn/Ni battery, the electrolyte has high concentration of alkaline zincate solution and the quantity of zinc deposit was massive , so the substrates may have different effects.

What is a highly stable zinc iodine single flow battery?

Xie, C. et al. Highly stable zinc–iodine single flow batteries with super high energy density for stationary energy storage. Energy Environ. Sci. 12, 1834–1839 (2019). Xie, C. et al. A highly reversible neutral zinc/manganese battery for stationary energy storage.

Are aqueous zinc flow batteries safe?

Aqueous zinc flow batteries (AZFBs) with high power density and high areal capacity are attractive, both in terms of cost and safety. A number of fundamental challenges associated with out-of-plane...

Guess what you want to know

-

Angola Flow Battery Company

Angola Flow Battery Company

-

5mw all-vanadium flow battery

5mw all-vanadium flow battery

-

Estonian flow battery prices

Estonian flow battery prices

-

Vanadium flow battery energy storage trends

Vanadium flow battery energy storage trends

-

Zinc flow battery

Zinc flow battery

-

Semi-solid lithium flow battery

Semi-solid lithium flow battery

-

Communication base station flow battery cost details

Communication base station flow battery cost details

-

Niue Solar Base Station Flow Battery Location

Niue Solar Base Station Flow Battery Location

-

South Sudan 5G Communication Base Station Flow Battery Construction Project

South Sudan 5G Communication Base Station Flow Battery Construction Project

-

All-vanadium redox flow battery market share

All-vanadium redox flow battery market share

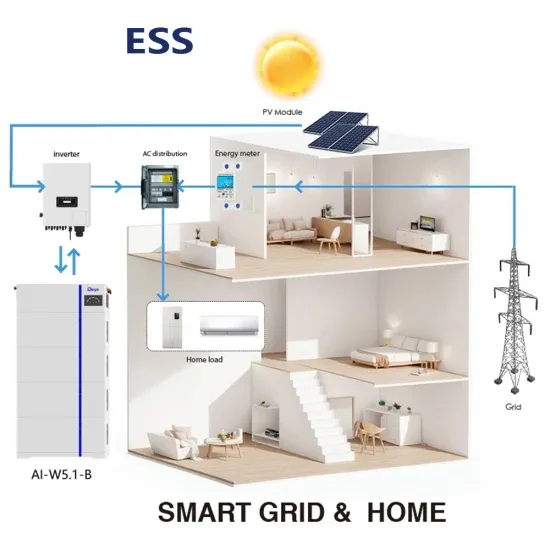

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.