Beginner''s guide to create a solar project schedule

The scope of work and schedule for most rooftop solar projects is quite similar. Here are some guidelines on how you can easily create

Get a quote

Cost Breakdown of a Solar Panel: From

This article delves into the comprehensive cost breakdown of solar panels, exploring the various facets of manufacturing costs, marketing and

Get a quote

How Much Does It Cost to Start a Solar Panel Manufacturing Plant?

In summary, starting a solar panel manufacturing plant involves navigating a complex landscape of costs and considerations, including initial investments, operating expenses, and

Get a quote

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride, copper indium gallium

Get a quote

Solar Inverter Cost Analysis from Manufacturing

Introduction In the realm of solar power systems, the solar inverter stands out as a key player, seamlessly converting solar energy into usable

Get a quote

Estimating the Setup Cost for a Solar Plant in India

Discover the investment required for a solar plant setup cost in India. Explore incentives, costs, and benefits for a sustainable energy future.

Get a quote

Solar Panel

Solar panel refers either to a photovoltaic module, a solar thermal energy panel, or to a set of solar photovoltaic (PV) modules electrically connected and mounted on a supporting structure.

Get a quote

How to Analyze Solar Panel Manufacturing Costs Efficiently

Empower your solar panel manufacturing cost strategy by accurately tracking both fixed and variable expenses. Use accounting tools to automate expense tracking and

Get a quote

What Are the 9 Operating Costs of a Solar Panel Manufacturing

Discover the 9 key ongoing expenses for running a solar panel manufacturing plant. Get actionable insights to control costs and boost efficiency.

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride,

Get a quote

Design and Cost Analysis of 100 MW Perovskite Solar

Previous studies comparing perovskite to single-junction (S-J) silicon solar cells predicted a relatively low production cost per panel for PSCs

Get a quote

Solar Panel Manufacturing Plant Setup 2025: Industry Trends,

Detailed information related to the process flow and various unit operations involved in the solar panel manufacturing plant project is elaborated in the report. These include: Land,...

Get a quote

Microsoft Word

This analysis suggests optimal requirements (of plant size, manufacturing processes, raw material procurement, financial incentives, etc.) to attain economies of scale and become price

Get a quote

Work Breakdown Structure Example | Proteus Project Software

A work breakdown structure example for a complex engineering project in the energy sector, such as building a new solar power plan

Get a quote

Solar Panel Manufacturing Plant Setup Cost 2025

IMARC Group''s report, titled " Solar Panel Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,

Get a quote

Solar Panel Manufacturing Cost: A Complete Factory Breakdown

Starting a solar panel factory? Get a detailed cost breakdown for machinery, buildings, and working capital for 25 MW, 100 MW, and 800 MW production lines.

Get a quote

Solar Panel Manufacturing Plant 2024: Detailed Project Report

Key Questions Addressed in the Report on Solar Panel Manufacturing Project: How has the performance of the solar panel market been thus far, and what can be expected in the

Get a quote

Breaking down solar farm costs: Free template inside

How to properly understand and efficiently allocate the costs of your solar plant project. Bonus track included: a PV plant bill of quantities.

Get a quote

Cost Breakdown of a Solar Panel: From Manufacturing to Market

This article delves into the comprehensive cost breakdown of solar panels, exploring the various facets of manufacturing costs, marketing and distribution expenses,

Get a quote

Solar Power Plant Construction Timeline

Building a solar power plant is an exciting step toward harnessing clean, renewable energy. Whether you''re a business looking to reduce energy costs

Get a quote

Utility-Scale PV | Electricity | 2024 | ATB | NREL

Units using capacity above represent kWAC. 2024 ATB data for utility-scale solar photovoltaics (PV) are shown above, with a base year of 2022. The Base Year estimates rely on modeled

Get a quote

Solar System Installation Prices: A Breakdown of the Costs

Learn about the factors that affect solar system installation prices, including the size of your system, and the type of panels you should choose. Read Now!

Get a quote

6 FAQs about [Solar Panel Factory Project Breakdown]

How a solar panel manufacturing plant can reduce fuel and transportation costs?

Opt for energy-efficient logistics solutions to decrease fuel and transportation expenses. The energy consumption of a solar panel manufacturing plant is not just about powering machinery. It impacts the overall solar panel manufacturing costs significantly.

How does energy consumption affect a solar panel manufacturing plant?

The energy consumption of a solar panel manufacturing plant is not just about powering machinery. It impacts the overall solar panel manufacturing costs significantly. For instance, energy expenses can account for up to 30% of total operational costs in similar facilities.

How important is the location of a solar panel manufacturing plant?

How important is the location of the manufacturing plant? The location of your solar panel manufacturing plant greatly affects operational costs, supply chain efficiency, and access to skilled labor. What equipment is essential for solar panel manufacturing?

How to reduce solar panel manufacturing costs?

In a state-of-the-art facility like SolarTech Innovations, raw materials including high-purity silicon and specialty glass dominate the solar panel manufacturing costs. Bulk purchase agreements and strategic sourcing have proven to reduce these photovoltaic manufacturing expenses significantly.

How do I start a solar panel manufacturing plant?

In short, starting a solar panel manufacturing plant involves a complex web of financial considerations that must be navigated to ensure success. Overview of solar panel manufacturing costs. Breakdown of capital expenses. Analysis of operating costs. Importance of location and facility size. Government incentives and subsidies.

How does energy management affect solar panel manufacturing costs?

It impacts the overall solar panel manufacturing costs significantly. For instance, energy expenses can account for up to 30% of total operational costs in similar facilities. Therefore, using energy-efficient equipment and implementing regular energy audits becomes essential for managing solar panel plant expenses.

Guess what you want to know

-

South Korea Solar Panel Photovoltaic Power Generation Project

South Korea Solar Panel Photovoltaic Power Generation Project

-

Solar thermal equipment for communication base station solar panel factory

Solar thermal equipment for communication base station solar panel factory

-

Building a solar panel factory

Building a solar panel factory

-

Solar panel expansion project

Solar panel expansion project

-

Gabon Solar Panel Photovoltaic Power Generation Project

Gabon Solar Panel Photovoltaic Power Generation Project

-

Solar Panel Smart Factory

Solar Panel Smart Factory

-

New Energy Solar Panel Factory

New Energy Solar Panel Factory

-

Angola Solar Photovoltaic Panel Project

Angola Solar Photovoltaic Panel Project

-

Thailand Solar Photovoltaic Panel Project

Thailand Solar Photovoltaic Panel Project

-

Brunei Photovoltaic Solar Panel Factory

Brunei Photovoltaic Solar Panel Factory

Industrial & Commercial Energy Storage Market Growth

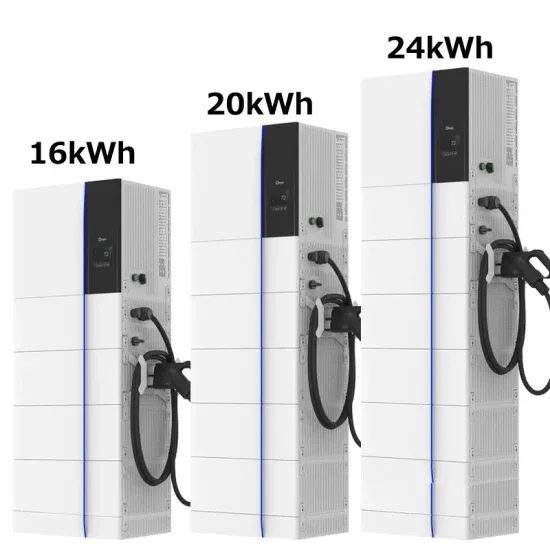

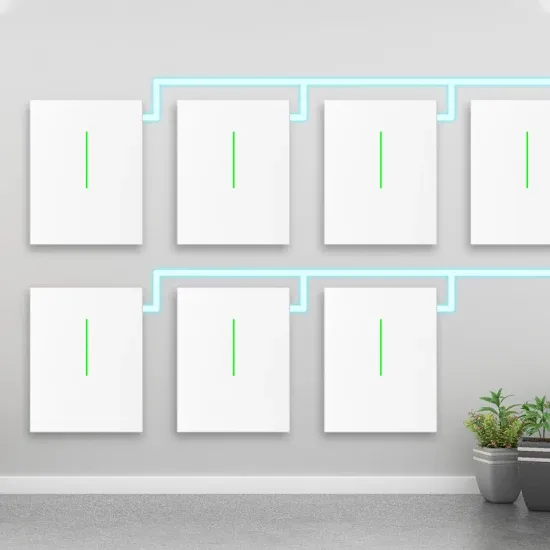

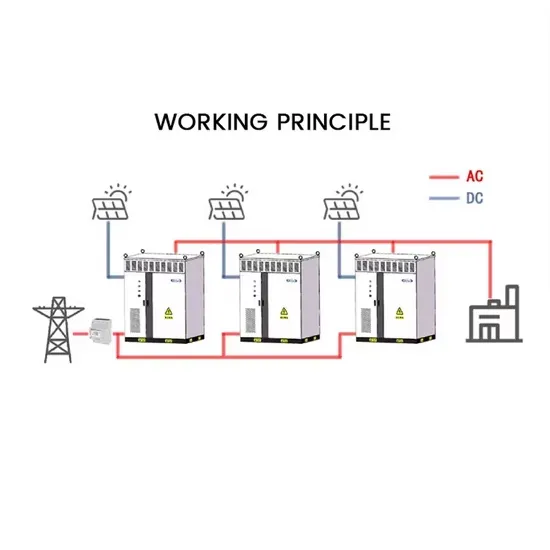

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

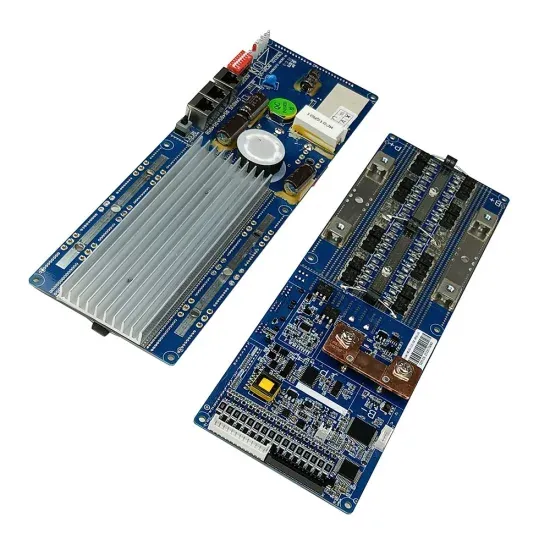

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.