National Survey Report of PV Power Applications in China

1 INSTALLATION DATA The PV power systems market is defined as the market of all nationally installed (terrestrial) PV applications with a PV capacity of 40 W or more. A PV system

Get a quote

The Complete Sizing Guide for Residential LFP Batteries, PV

Appropriately sizing the capacity of BESSs is key to guaranteeing adequate performance while minimizing investment costs. Insufficient capacity reduces the self

Get a quote

Solar photovoltaics in Europe

The production volume of electricity from solar photovoltaic power in the European Union has been steadily increasing in the last years. In 2024, the EU''s solar PV power

Get a quote

Solar inverter sizing: Choose the right size inverter

Understanding the inverter DC-to-AC ratio The DC-to-AC ratio — also known as Inverter Loading Ratio (ILR) — is defined as the ratio of installed DC capacity

Get a quote

Solar plants typically install more panel capacity

For economic and engineering reasons, capacity values reported in DC typically are 10% to 30% higher than those reported in AC capacity.

Get a quote

PV Inverters

The Right Inverter for Every Plant A large number of PV inverters is available on the market – but the devices are classified on the basis of three important characteristics: power, DC-related

Get a quote

Solar energy

The total installed capacity of solar PV reached 1 865 GW globally by the end of 2024, representing a remarkable increase from 710 GW at the end of 2020. Over 451 GW of new

Get a quote

Photovoltaic Capacity

Installed photovoltaic (PV) capacity exceeded 500 GW at the end of 2018, and by 2023 an additional 500 GW of PV capacity is projected to be installed which will bring us into the era of

Get a quote

Solar inverter size: Calculate the right size for your

More specifically, the inverter ensures that enough energy can flow from your solar panels to the grid and load or if installed with a battery, from and to the

Get a quote

Solar PV Modules and Inverters Market Trends and

Solar PV Modules and Inverters Market Trends and Analysis by Technology, Installed Capacity, Generation, Key Players and Forecast to

Get a quote

Utility-Scale PV | Electricity | 2023 | ATB | NREL

The DC-to-AC ratio — also known as Inverter Loading Ratio (ILR) — is defined as the ratio of installed DC capacity to the inverter''s AC power rating. It often makes sense to oversize a

Get a quote

Solar plants typically install more panel capacity relative to their

For economic and engineering reasons, capacity values reported in DC typically are 10% to 30% higher than those reported in AC capacity. This ratio is often referred to as the

Get a quote

The Complete Sizing Guide for Residential LFP

Appropriately sizing the capacity of BESSs is key to guaranteeing adequate performance while minimizing investment costs. Insufficient capacity

Get a quote

How many solar panels can an inverter handle

A general rule of thumb is to have an inverter capacity that is between 80% to 125% of your solar panels'' capacity. This range accounts for

Get a quote

Utility-Scale PV | Electricity | 2023 | ATB | NREL

2023 ATB data for utility-scale solar photovoltaics (PV) are shown above, with a Base Year of 2021. The Base Year estimates rely on modeled capital expenditures (CAPEX) and operation

Get a quote

Solar Industry Research Data – SEIA

American Solar Deployment Grows at Record Pace Solar has seen massive growth since 2000. There are now 248 gigawatts (GW) of solar capacity installed nationwide, enough to power

Get a quote

Installed solar energy capacity

The renewable power capacity data represents the maximum net generating capacity of power plants and other installations that use renewable energy sources to produce

Get a quote

Photovoltaic inverter and installed capacity

ILR is the quotient of installed DC power capacity of PV array to AC power output rating of the inverter (Zidane et al., 2021).Where, P inv is the Inverter AC output power rating.

Get a quote

Solar inverter sizing: Choose the right size inverter

The DC-to-AC ratio — also known as Inverter Loading Ratio (ILR) — is defined as the ratio of installed DC capacity to the inverter''s AC power rating. It often makes sense to oversize a

Get a quote

Photovoltaic inverters and installed photovoltaic capacity

for grid connected solar PV systems have been highlighted. The state-of-the-art features of multi-functional grid-connected solar PV inverter for increased penetration

Get a quote

Utility-Scale PV | Electricity | 2021 | ATB | NREL

PV system inverters, which convert DC energy/power to AC energy/power, have AC capacity ratings; therefore, the capacity of a PV system is rated in MW AC,

Get a quote

Step-by-Step Design of Large-Scale Photovoltaic Power Plants

Short- circuit current of the PV module Temperature coefficient at maximum expected temperature Rated PV installed power A nominal irradiance level Inverter downsize coefficient (nominal

Get a quote

How to Do Solar Panel Calculations? (Complete

What Is a Solar Panel? A solar panel is a photovoltaic (PV) module that converts sunlight into direct current (DC) energy. This energy then flows

Get a quote

Required vs Installed AC and DC power

The starting point for all Solar PV facility designs is determining how much power the facility can or should produce. There are typically two different approaches.

Get a quote

How many solar panels can an inverter handle

A general rule of thumb is to have an inverter capacity that is between 80% to 125% of your solar panels'' capacity. This range accounts for energy losses that occur in the

Get a quote

PV Inverters

The rated capacity of the PV array may be up to ten percent above the rated capacity of the inverter. If an inverter is greatly undersized, this can have a negative effect on plant yield,

Get a quote

6 FAQs about [Photovoltaic installed capacity and inverter capacity]

Do solar inverters have a rated capacity?

Ratings on solar inverters often give the false impression that you can connect as many panels as you like, as long as you’re under the stated power output. This leads to a misconception that exceeding the rated capacity is acceptable if you distribute loads wisely.

What is the DC capacity factor of a solar PV facility?

This approach applies to not just capacity values but also to costs and operation characteristics. For example, the AC capacity factor for solar PV facilities operating in 2017 was 27%. If this value were estimated using DC capacity, the DC capacity factor would be about 22%.

How many solar panels can an inverter handle?

To effectively determine the number of solar panels an inverter can handle, you must first assess the size of your solar panel array. The overall capacity of your solar installation is defined by the wattage and number of panels. You can expect that the inverter should match or slightly exceed the combined wattage produced by the solar panels.

How many solar panels can a 5 kW inverter use?

You will also need to consider the wattage of the solar panels you plan to use. For example, if you have a 5 kW inverter and each of your solar panels is rated at 300 watts, you can calculate the maximum number of panels by dividing the inverter’s capacity by the panel wattage: 5,000 watts (inverter) / 300 watts (panel) = approximately 16.67.

What is the average solar inverter loading ratio?

Inverter loading ratios are higher for larger solar power plants. At the end of 2016, smaller plants—those one megawatt (MW) or less in size—had an average ILR of 1.17, while larger plants—those ranging from 50 MW to 100 MW—had an ILR of 1.30. As solar plants have gotten larger, inverter loading ratios have increased.

How much power does a solar inverter produce?

Typical outputs are 5 kW for private home rooftop plants, 10 – 20 kW for commercial plants (e.g., factory or barn roofs) and 500 – 800 kW for use in PV power stations. 2. Module wiring The DC-related design concerns the wiring of the PV modules to the inverter.

Guess what you want to know

-

Photovoltaic inverter manufacturers and their capacity

Photovoltaic inverter manufacturers and their capacity

-

Small capacity photovoltaic combiner box

Small capacity photovoltaic combiner box

-

Zimbabwe photovoltaic inverter installation factory

Zimbabwe photovoltaic inverter installation factory

-

Inverter in photovoltaic system

Inverter in photovoltaic system

-

Huawei photovoltaic communication base station inverter

Huawei photovoltaic communication base station inverter

-

Photovoltaic dual inverter box grid connection

Photovoltaic dual inverter box grid connection

-

Photovoltaic inverter tracking

Photovoltaic inverter tracking

-

Nigeria photovoltaic and wind power inverter manufacturers

Nigeria photovoltaic and wind power inverter manufacturers

-

25kw photovoltaic inverter

25kw photovoltaic inverter

-

Does the photovoltaic inverter use Zhahuijue

Does the photovoltaic inverter use Zhahuijue

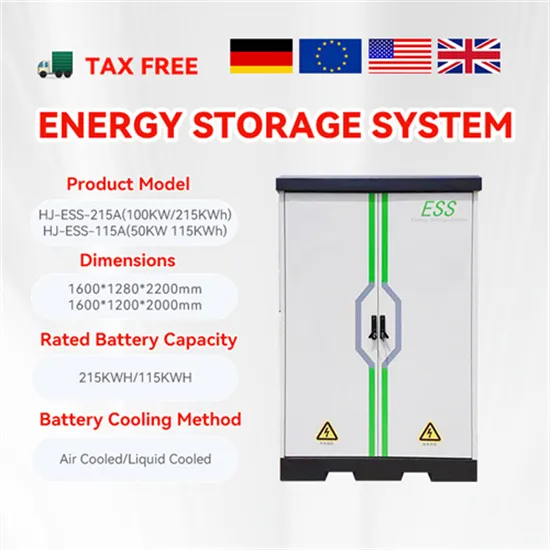

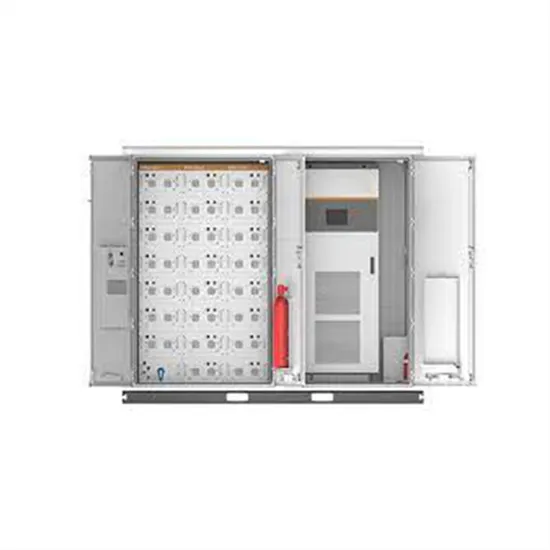

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

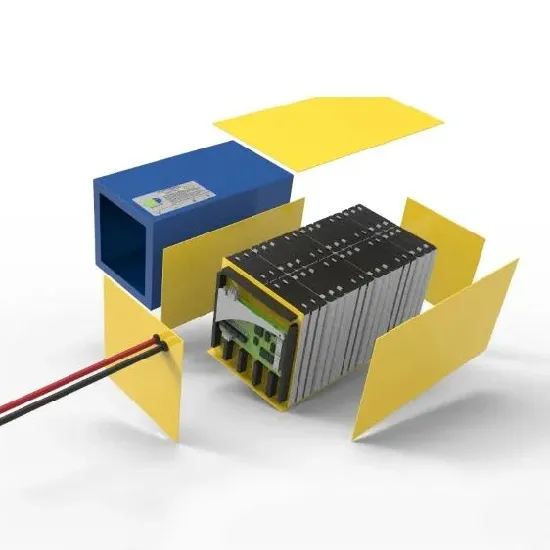

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.