A Comprehensive Guide to Understanding MPPT in

MPPT, or Maximum Power Point Tracking, is a critical technology employed in solar string inverters to optimize the performance of photovoltaic (PV) solar

Get a quote

Best Solar Monitoring Systems For 2025

Solar monitoring systems show real-time and historical solar production data. The best systems can track the production of individual solar modules within an array and help identify problems

Get a quote

Design and Evaluation of a Photovoltaic Inverter with Grid

This thesis investigates the control of variable-frequency sources as conventional syn-chronous machines and provides a detailed design procedure of this control structure for photovoltaic

Get a quote

A review on single-phase boost inverter technology for low power

Solar Photovoltaic (SPV) inverters have made significant advancements across multiple domains, including the booming area of research in single-stage boosting inverter

Get a quote

Solar Tracking System: Working, Types, Pros, and Cons

Solar Tracking System Price The tracking equipment alone can range from $500 to over $1,000 per panel. Adding solar trackers can

Get a quote

MPPT methods for solar PV systems: a critical review based on tracking

An efficient maximum power point tracking (MPPT) method plays an important role to improve the efficiency of a photovoltaic (PV) generation system. This study provides an

Get a quote

Solar Inverter monitoring

Most of manufacturers of inverters provide free portals and softwares that allow to monitor and control photovoltaic generators. This list presents some of them.

Get a quote

Design and Evaluation of a Photovoltaic Inverter with Grid-Tracking

This thesis applies the concept of a virtual-synchronous-machine- (VSM-) based control to a conventional 250-kW utility-scale photovoltaic (PV) inverter. VSM is a recently

Get a quote

Solar Inverter Monitoring

A solar inverter monitoring system is a set of tools and technologies that allow you to track the performance of your solar inverter and the overall solar energy system.

Get a quote

Solar Tracking System: Working, Types, Pros, and Cons

In this blog, let''s explore the working, types, applications, and costs of solar tracking systems. These trackers are commonly used for positioning

Get a quote

Maximum power point tracking

OverviewBackgroundImplementationClassificationPlacementBattery operationFurther readingExternal links

Maximum power point tracking (MPPT), or sometimes just power point tracking (PPT), is a technique used with variable power sources to maximize energy extraction as conditions vary. The technique is most commonly used with photovoltaic (PV) solar systems but can also be used with wind turbines, optical power transmission and thermophotovoltaics.

Get a quote

High performance of three-level T-type grid-connected photovoltaic

A three-phase three-level transformerless T-type grid-connected inverter system with three-level boost maximum power point tracking converter is introduced in this article for

Get a quote

Maximum Power Point Tracking Explained

An inverter without an MPPT circuit would result in lower efficiency operating outputs between any PV module (or string) and the inverter. Unless the inverter can match the

Get a quote

System Design

Use the System Design variables to size the photovoltaic system and choose tracking options. If your system includes battery storage, configure the battery bank on the Battery...

Get a quote

A CC/VC-based power tracking method for photovoltaic inverter

This paper proposes a current-control/voltage-control based hybrid power tracking (CVPT) method for voltage-controlled two-stage PV inverters, which can cope with the bi

Get a quote

Design and Evaluation of a Photovoltaic Inverter with Grid

Chapter 3 discusses the basics of a phase-locked loop and the design of a grid-tracking dq-frame PLL-oriented vector control scheme for PV inverter with active and reactive power injection

Get a quote

Solar Tracking System: Working, Types, Pros, and Cons

In this blog, let''s explore the working, types, applications, and costs of solar tracking systems. These trackers are commonly used for positioning solar panels to maximize sunlight

Get a quote

MPPT – Everything You Need to Know About

In designs using string inverters, it is the inverters that "choose" the operating point. The ability of the inverters to locate the operating point of a solar array

Get a quote

How to Monitor and Track Solar Inverter Performance

This article provides a comprehensive guide to understanding how to effectively monitor and track solar inverter performance, ensuring optimal energy generation.

Get a quote

Photovoltaic String Inverters and Shade-Tolerant Maximum

Historically, dynamic maximum power point tracking (MPPT) of the singular power peaks common to homogenously irradiated PV arrays and modules has provided adequate PV harvest

Get a quote

Maximum power point tracking

The Perturb and Observe (P&O) algorithm adjusts the operating voltage of a photovoltaic (PV) system to track the maximum power point (MPP). By periodically perturbing the voltage and

Get a quote

How to Monitor and Track Solar Inverter Performance

This article provides a comprehensive guide to understanding how to effectively monitor and track solar inverter performance, ensuring optimal

Get a quote

Optimal tracking for PV three-phase grid-connected inverter with

The paper presents a simple yet accurate tracking control strategy for a three-phase grid-connected inverter with an LC filter. Three-phase inverters are used to integrate

Get a quote

Recent trends in solar PV inverter topologies

Series connection of solar PV modules decreases efficiency and reliability over parallel connection (Patrao et al., 2011). But, parallel connection of PV modules offers lower

Get a quote

6 FAQs about [Photovoltaic inverter tracking]

How to monitor and control a photovoltaic generator?

Most of manufacturers of inverters provide free portals and softwares that allow to monitor and control photovoltaic generators. This list presents some of them. FIMER inverters (ABB brand) solar inverters can be connected to different monitoring and control systems via a selection of fieldbus and interface adapters.

How does a PV inverter work?

In this manner, the PV inverter operates similar to a fixed reactor bank, which, when switched on, provides a fixed amount of reactive power based on the reactive power capabaility de-signed for the bank. However, the PV inverter will continue to also inject a set amount of active power based on the current load of the system.

Should you use passive solar trackers?

Given their lower accuracy, you can use passive trackers for simple PV systems – but not for much else. Passive solar trackers are also not as efficient in cold temperatures because the liquid inside the tracker usually takes time to heat up. As with any addition to a solar panel system, there are pros and cons to solar trackers.

How do Fimer solar inverters work?

FIMER inverters (ABB brand) solar inverters can be connected to different monitoring and control systems via a selection of fieldbus and interface adapters. This offering is complemented with a series of data loggers and controllers as well as with string monitoring junction boxes and environmental sensors. All-in-one system monitoring portal.

Is there a phase tracking system for three phase utility interface inverters?

S. K. Chung, “A phase tracking system for three phase utility interface inverters,” IEEE Transactions on Power Electronics, vol. 15, no. 3, pp. 431–438, May 2000.

How do voltage source inverters work?

By controlling the DC-link voltage and facilitating the power transmission to the utility grid, the Voltage Source Inverters (VSI) in a single-stage PV system enables Maximum Power Point Tracking (MPPT). An LC low-pass filter interfaces the VSC AC side with the grid.

Guess what you want to know

-

Photovoltaic inverter tracking

Photovoltaic inverter tracking

-

Belize Distributed Photovoltaic Inverter Plant

Belize Distributed Photovoltaic Inverter Plant

-

Is the photovoltaic grid-connected inverter suitable for civilian use

Is the photovoltaic grid-connected inverter suitable for civilian use

-

Photovoltaic inverter DCAC module

Photovoltaic inverter DCAC module

-

Huawei photovoltaic inverter high power

Huawei photovoltaic inverter high power

-

Photovoltaic energy storage inverter power supply

Photovoltaic energy storage inverter power supply

-

Morocco photovoltaic module inverter manufacturer

Morocco photovoltaic module inverter manufacturer

-

Photovoltaic array and inverter

Photovoltaic array and inverter

-

Photovoltaic three-phase inverter specifications

Photovoltaic three-phase inverter specifications

-

Photovoltaic panel output and inverter output

Photovoltaic panel output and inverter output

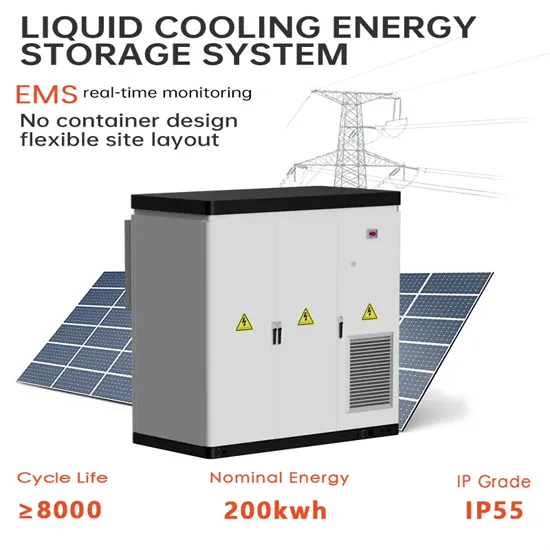

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.