batteries

Regenerative EV systems don''t just blindly rectify and apply the regen voltage to the motor. Relying on the BMS for this is like relying on the airbags when you park your car.

Get a quote

What Is a BMS PCB Board? A Beginner''s Guide to Battery

A BMS PCB board (Battery Management System Printed Circuit Board) is a specialized circuit board designed to monitor and protect battery packs. It acts as the "brain" of

Get a quote

BMS Regulates the Battery and Charging Speed

A basic understanding of the charging effects of BMS can effectively address your concerns and help to optimize the battery life of your electric vehicle. Impact of BMS on

Get a quote

Understanding the Protections Provided by a Battery Management System (BMS)

Discharging a battery beyond its designed minimum voltage can cause irreversible damage, leading to reduced capacity and shortened battery life. The BMS tracks the battery''s

Get a quote

Comprehensive Guide to BMS and Protection Circuit Modules

Over-discharging can significantly reduce a battery''s capacity, lowering the voltage below safe levels (typically around 2.7V for lithium-ion cells). PCMs prevent over-discharge by cutting off

Get a quote

What is a Battery Management System (BMS)? Essential Guide

A Battery Management System (BMS) safeguards lithium-ion batteries by monitoring voltage, current, and temperature, preventing overcharge, discharge, and thermal

Get a quote

Does a "normal" lithium battery BMS limit the current going into

If I hook up a 42 V voltage source with an absurd peak amperage to a 42 V battery through a BMS, will it protect the battery from too much current?

Get a quote

How Do Voltage Thresholds Impact BMS Protection Accuracy?

Voltage thresholds in a Battery Management System (BMS) determine how accurately the system prevents overcharge, over-discharge, and thermal risks. Properly

Get a quote

How BMS Overvoltage Protection Guard the Electrical

BMS overvoltage protection is used to prevent a battery or battery pack from rising above the voltage level of a predefined safety limit.

Get a quote

52V 30Ah eBike Battery | Samsung 50G Cells | for Hub Mid-Drive

The battery is equipped with an intelligent Bluetooth battery management system (BMS), which can monitor voltage, temperature and capacity in real time through a dedicated application to

Get a quote

How High-Voltage BMS Enhance Safety and Battery Lifetimes

By ensuring better battery-monitor accuracy and increasing system-level safety, the BMS helps maintain efficient energy usage and delays premature battery degradation, prolonging BESS

Get a quote

How does the BMS ensure the safety of the battery cells

Overcharge Protection: The BMS monitors the voltage of each cell and stops the charging process when a predetermined maximum voltage

Get a quote

What is a BMS or Battery Management System?

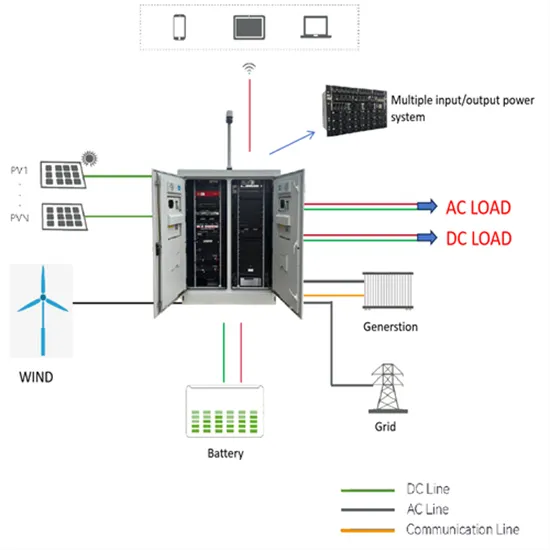

Overall, the integration of an EMS with a BMS can enhance the efficiency and reliability of a building''s energy management system, improving

Get a quote

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

A BMS monitors the battery''s voltage and current levels to ensure they remain within safe limits. It disconnects the battery when the voltage drops to a predetermined

Get a quote

How BMS Works on Batteries in EV: Boosting

Yes, by managing charging rates, temperature, voltage, and performing cell balancing, the BMS helps reduce wear and tear on the battery.

Get a quote

Exactly HOW does the BMS Stop the Charging Process?

Correct. Your EG4 has predefined voltage settings that cannot be changed and it will charge to 100% unless something stops it. And nothing in your diagram will stop it. Unless

Get a quote

How to Detect and Keep Types of BMS Voltage for

BMS is an important part of maintaining the normal operation of a battery system, and balancing the BMS voltage is particularly critical.

Get a quote

How BMS Works on Batteries in EV: Boosting Performance,

Yes, by managing charging rates, temperature, voltage, and performing cell balancing, the BMS helps reduce wear and tear on the battery. This ultimately extends the

Get a quote

The Battery Management System: How It Enhances Safety and

BMS battery optimization features also prevent damage, protect performance, and enhance battery longevity. However, optimizing technologies mainly focus on cell balancing,

Get a quote

Understanding the Protections Provided by a Battery

Discharging a battery beyond its designed minimum voltage can cause irreversible damage, leading to reduced capacity and shortened battery life. The BMS tracks the battery''s

Get a quote

Your Guide to Battery Management Systems (BMS)

Changes in voltage can significantly reduce a battery''s life. The BMS circuit is connected to each individual cell within the battery pack. It samples the voltage of each cell

Get a quote

Mind that BMS: Charging & Discharging limits

For example, by having both the Elithion BMS and an AC motor inverter connected to a CAN bus will enable the BMS to reduce the motor torque as a cell''s voltage starts getting too low, and to

Get a quote

How does the BMS ensure the safety of the battery cells

Overcharge Protection: The BMS monitors the voltage of each cell and stops the charging process when a predetermined maximum voltage threshold is reached. Overcharging

Get a quote

BMS that can regulate voltage and current?

Had a couple people on Facebook groups insistent that there are battery systems that come with a BMS that can manage the charging voltage and current. Anyone else come

Get a quote

Understanding the Role of the BMS in Modern Lithium Batteries

The BMS tracks the voltage of each cell in the pack, ensuring they stay within safe limits. If one cell drifts too high or low, the BMS can cut off charging or discharging to protect the battery.

Get a quote

6 FAQs about [Can BMS reduce the battery voltage ]

Why does the BMS stop charging?

The BMS will stop charging to prevent overcharging. If the voltage drops below 2.5V, the battery could be damaged and have reduced capacity. The BMS will stop discharging to protect the battery from over-discharging. 2. State of Charge (SOC) Calculation (Lithium-Ion Battery Example)

Why is a BMS important for lithium-ion batteries?

In summary, a BMS is vital for lithium-ion battery safety due to its role in monitoring performance and preventing dangerous situations. It protects against various risks while enhancing the battery’s lifespan and reliability. How Does a BMS Protect Lithium-Ion Batteries from Overcharging?

Why do you need a battery management system (BMS)?

The BMS provides overcurrent protection, which helps prevent fire risks. Overall, a BMS enhances battery reliability and safety during charging and discharging operations. Without a BMS, lithium-ion batteries can overcharge or over-discharge. This condition can lead to battery damage or even fires.

Does a BMS improve battery life?

Yes, by managing charging rates, temperature, voltage, and performing cell balancing, the BMS helps reduce wear and tear on the battery. This ultimately extends the battery's lifespan and ensures optimal performance over time. How does the BMS affect the EV's driving range?

Can a battery management system prevent over-discharging in lithium-ion batteries?

Yes, a Battery Management System (BMS) can prevent over-discharging in lithium-ion batteries. A BMS monitors the battery’s voltage and current levels to ensure they remain within safe limits. It disconnects the battery when the voltage drops to a predetermined threshold, effectively preventing further discharge.

How does a BMS work?

This is one of the most important functions of a BMS. Changes in voltage can significantly reduce a battery’s life. The BMS circuit is connected to each individual cell within the battery pack. It samples the voltage of each cell and compares it against predefined thresholds to ensure it remains within safe operating limits.

Guess what you want to know

-

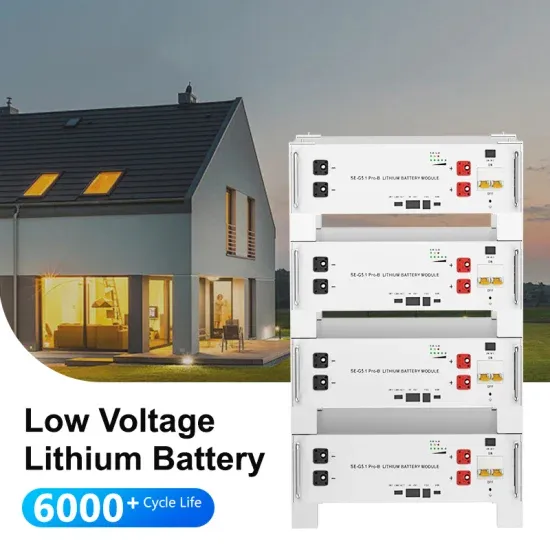

Is the voltage between the battery and the BMS high or low

Is the voltage between the battery and the BMS high or low

-

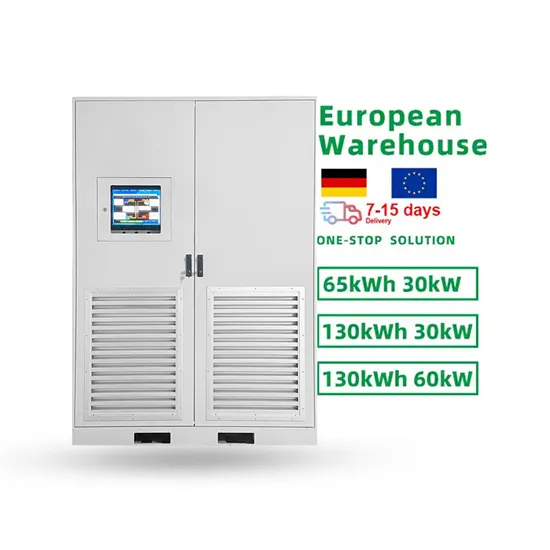

Industrial high voltage battery energy storage battery cabinet

Industrial high voltage battery energy storage battery cabinet

-

Latvian professional lithium battery BMS structure

Latvian professional lithium battery BMS structure

-

Lithium battery equipment needs BMS

Lithium battery equipment needs BMS

-

Lithium battery station cabinet BMS system

Lithium battery station cabinet BMS system

-

Colombian lithium battery BMS module

Colombian lithium battery BMS module

-

Tonga lithium battery BMS balancing

Tonga lithium battery BMS balancing

-

Chilean Battery Management System BMS

Chilean Battery Management System BMS

-

Uzbekistan BMS battery management control system

Uzbekistan BMS battery management control system

-

Libya BMS battery management power system architecture

Libya BMS battery management power system architecture

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.