Automotive battery management system (BMS)

Ensure optimal energy use and performance with reliable high-voltage BMS solutions that monitor and control charging, discharging and cell parameters.

Get a quote

Section 2 Battery Management System (BMS) and Sensors

Battery Management System (BMS) and Sensors This section will describe the function of the Battery Management System Control Module (BMS) and the sensors. The section explains

Get a quote

Comparing High Voltage Battery Management System with Low

In summary, the differences between high voltage battery management systems and low voltage BMS are significant and impact their suitability for various applications.

Get a quote

Voltage Settings for BMS, Chargers and Loads

BMS, Load and Charger voltage settings. When setting up your system, the various voltage settings on the BMS, Loads and Chargers are critical for a hassle free but safe system

Get a quote

How to Choose From High Voltage BMS and Low Voltage BMS?

High-voltage BMS and low-voltage BMS are two different types of battery management systems that are used to monitor, manage, and protect the critical components

Get a quote

Understanding Battery Management Systems (BMS)

Answer: Battery Management System (BMS) is a digital control unit that monitors and manages rechargeable batteries. It ensures batteries

Get a quote

Battery Management Systems (BMSs) Monitor the

There are two methods to the cell balancing function, which is an important function of a BMS. One is the passive method, in which a discharge switch is used to forcibly

Get a quote

How does BMS really work during charge and (top)

You only see a noticeable voltage difference at high or low states of charge: that''s where you balance. In order to balance at that 40% mark, you

Get a quote

Reference Board: Low-Voltage Battery Management System

The Role of the Low-Voltage Battery Management System In the KIT24 electric race car, the low-voltage BMS is instrumental in facilitating high-performance operation

Get a quote

Understanding Battery Management Systems: How They Keep

Overcharging occurs when excess voltage continues to flow into the battery after it has reached full charge. This causes premature aging, and the excess heat becomes a fire risk.

Get a quote

What Does BMS Mean in Lithium Batteries?

If the voltage becomes too high or too low, it can damage the battery and reduce its lifespan. The BMS ensures that the battery stays within a safe voltage range, optimizing its

Get a quote

How Does A Battery Management System Work?

The BMS employs high-precision analog-to-digital converters to measure individual cell voltages with accuracy typically within ±2mV. For a

Get a quote

Understanding the Role of the BMS in Modern Lithium Batteries

The BMS tracks the voltage of each cell in the pack, ensuring they stay within safe limits. If one cell drifts too high or low, the BMS can cut off charging or discharging to protect the battery.

Get a quote

The Complete Guide To A Battery Management System

Lithium-ion batteries, especially custom lithium ion battery packs, need a BMS (Battery Management System) to ensure the battery is reliable

Get a quote

How Does A Battery Management System Work?

The BMS employs high-precision analog-to-digital converters to measure individual cell voltages with accuracy typically within ±2mV. For a typical lithium-ion battery pack, the

Get a quote

High Voltage Battery Management System for Electric

Battery management system for electric vehicles is a crucial supervisory system that ensures battery pack safety. Nowadays, with the

Get a quote

Understanding Battery Management Systems: How

Overcharging occurs when excess voltage continues to flow into the battery after it has reached full charge. This causes premature aging, and the

Get a quote

Comparing High Voltage Battery Management System with Low Voltage BMS

In summary, the differences between high voltage battery management systems and low voltage BMS are significant and impact their suitability for various applications.

Get a quote

The Complete Guide To A Battery Management System

Lithium-ion batteries, especially custom lithium ion battery packs, need a BMS (Battery Management System) to ensure the battery is reliable and safe. The battery

Get a quote

7. Troubleshooting and Support

Background: If, after a low cell voltage or low SoC event, the BMS does not detect a charge voltage within 5 minutes, the BMS will enter OFF mode. In OFF mode, the ATC and ATD

Get a quote

High Voltage BMS For Energy Storage System and

Low Voltage (LV) battery packs are typically used in light electric and hybrid vehicles, two and three wheelers. HV battery packs are typically

Get a quote

A Look Inside Battery-Management Systems | Electronic Design

A battery-management system (BMS) typically consists of several functional blocks, including cutoff field-effect transmitters (FETs), fuel-gauge monitor, cell-voltage

Get a quote

Wireless BMS vs. Wired BMS: Who is the Key Battery

A wireless BMS is used to monitor and optimize rechargeable battery packs in various cases without the need for physical wired connections.

Get a quote

General Fault Settings

An isolation fault develops when there is a breakdown in the insulation between the high voltage battery pack and the ground. This can happen if a wire is sliced, or the insulation cracks or if

Get a quote

⚡ The Guardian Inside the Battery: Why BMS Is the Silent Hero

This post explores what BMS is, why it''s critical, the types of BMS, and the differences between low-voltage and high-voltage applications —all in language that resonates

Get a quote

Battery Management System | Functions & Building

Modern BMS has Bluetooth and Universal Asynchronous Receiver-Transmitter (UART) connectivity capabilities. Improvement of Battery Performance A

Get a quote

Battery Monitor vs Battery Management System: Key Insights

3 days ago· What is the difference between a battery monitor and a battery management system (BMS)? A lithium ion battery monitor and a battery management system are often confused.

Get a quote

How does BMS really work during charge and (top) balance?

You only see a noticeable voltage difference at high or low states of charge: that''s where you balance. In order to balance at that 40% mark, you need to wait a very, very long

Get a quote

6 FAQs about [Is the voltage between the battery and the BMS high or low ]

Do lithium ion batteries need a BMS system?

Lithium-ion batteries, especially custom lithium ion battery packs, need a BMS (Battery Management System) to ensure the battery is reliable and safe. The battery management system is the brain of the lithium battery and reports the status and health of the battery. Let’s get a better understanding from this article. What is a BMS System?

What does BMS mean in a battery?

At its core, BMS stands for Battery Management System. It's an essential component for lithium-ion batteries, which are commonly used in electric vehicles (EVs), energy storage systems (ESS), and other devices that require rechargeable batteries.

How does a BMS charge a lithium ion battery?

As cells approach their maximum voltage (typically 4.2V for lithium-ion), the BMS gradually reduces charging current following a constant-current/constant-voltage (CC/CV) profile. The charging cutoff occurs when both voltage and current criteria are met – usually when current drops below C/20 (5A for a 100Ah battery) while at maximum voltage.

What is a battery management system (BMS)?

Modern lithium batteries are more than just rows of chemical cells—they're smart energy systems, and the Battery Management System (BMS) is their brain. Without a properly functioning BMS, even the most advanced battery pack can fail, shut down, or become a safety hazard.

What is a battery balancing system (BMS)?

The BMS works to balance the individual cells in the battery pack, ensuring that all cells are operating at the same voltage level. This balancing helps avoid cell imbalance, which can reduce battery efficiency and lifespan. As a result, a BMS significantly enhances the overall performance of the battery.

Why is hardware BMS better than smart battery management system?

The technology of hardware BMS is more stable than smart battery management systems. The software engineer codes the hardware BMS which manages or monitors the battery pack status. The BMS is the brain of the lithium-ion battery. We not only are good at designing and developing the BMS but also inspecting the risks.

Guess what you want to know

-

Energy storage high voltage battery and low voltage battery

Energy storage high voltage battery and low voltage battery

-

Occasional high voltage in new energy battery cabinet

Occasional high voltage in new energy battery cabinet

-

New energy battery cabinet internal communication high voltage disconnected

New energy battery cabinet internal communication high voltage disconnected

-

Can the inverter convert low voltage into high voltage

Can the inverter convert low voltage into high voltage

-

Can I use an inverter if the battery voltage is low

Can I use an inverter if the battery voltage is low

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

Djibouti outdoor communication battery cabinet communication high voltage system

Djibouti outdoor communication battery cabinet communication high voltage system

-

Low voltage inverter high voltage grid connection

Low voltage inverter high voltage grid connection

-

Energy storage cabinet battery current and voltage are high

Energy storage cabinet battery current and voltage are high

-

The voltage of one of the lithium battery strings is low

The voltage of one of the lithium battery strings is low

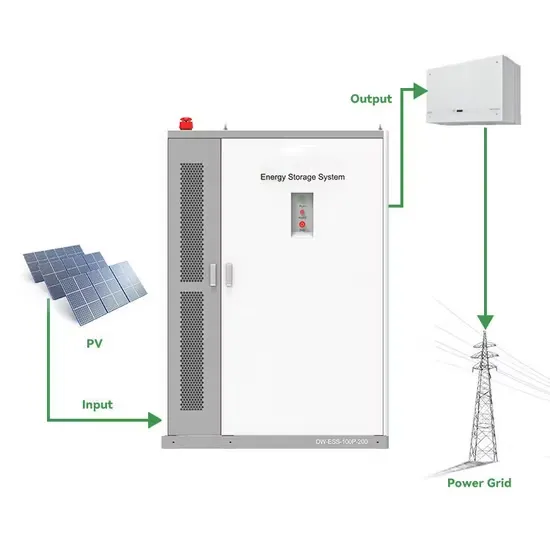

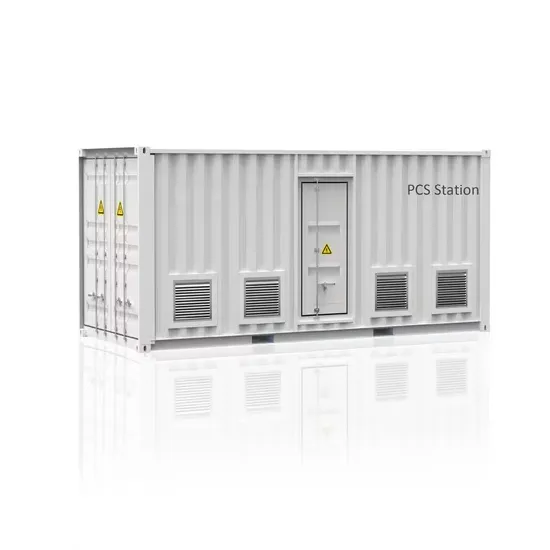

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

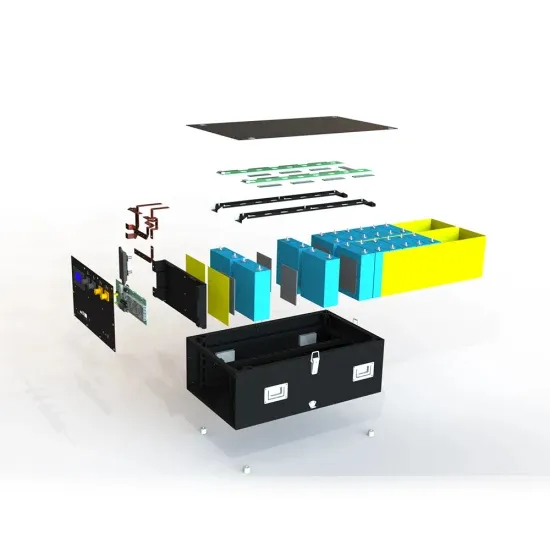

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.