Practical Implications of Series and Parallel

If a series string is required, it is important to have protections outside the string to prevent the possibility of low voltage protection being triggered for any battery

Get a quote

What to do if the lithium battery voltage is low? What is the reason

When encountering the situation of low voltage of lithium batteries, we need to understand the reasons in depth and take corresponding solutions.

Get a quote

Improved voltage transfer method for lithium battery string

The circuit reduces the leakage current to nanoampere scale and is integrated into the lithium battery string management chip, which is helpful for battery voltage balance and low cost.

Get a quote

What voltage is too low for lithium battery?

The critical low-voltage threshold for lithium-ion batteries is 2.5V per cell, below which irreversible damage occurs due to copper dissolution and SEI layer breakdown.

Get a quote

Practical Implications of Series and Parallel Installations of Lithium

If a series string is required, it is important to have protections outside the string to prevent the possibility of low voltage protection being triggered for any battery in the string.

Get a quote

Is draining a Li-Ion to 2.5 V harmful to a Li-ion cell?

Yes, lithium-ion cells undergo unwanted chemical reactions when discharged below 3 V, causing their internal resistance to be permanently and significantly raised. Their capacity

Get a quote

The Definitive Guide to LiFePO4 Lithium Battery

Thinking about using LiFePO4 lithium batteries for your upcoming project or application? Grasping their voltage characteristics is essential for

Get a quote

Strings, Parallel Cells, and Parallel Strings

One multi-purpose output is used to signal if discharging must stop due to a low cell voltage, and the other output is used to stop charging due to a high cell voltage (in the restricted state of

Get a quote

Understanding Lithium Battery Low Voltage Cutoff:

Lithium batteries have become a cornerstone in powering a multitude of devices, from smartphones and laptops to electric vehicles. A

Get a quote

BU-303: Confusion with Voltages

The phosphate-based lithium-ion has a nominal cell voltage of 3.20V and 3.30V; lithium-titanate is 2.40V. This voltage difference makes these chemistries

Get a quote

A minor-fault diagnosis approach based on modified variance for lithium

By calculating the modified variance of each battery voltage sequence in the lithium-ion battery strings online, the proposed approach is able to efficiently diagnose the initial minor

Get a quote

How to Solve the Imbalance between Li-ion Battery Pack Cells?

Here are 4 steps to solve the Imbalance between the Li-ion battery pack cells which will shorten the battery pack''s service life if not dealt with in time.

Get a quote

Understanding Lithium Battery Voltage: Ranges,

Lithium batteries have become a critical part of our daily lives, powering everything from cell phones to electric vehicles. Given their

Get a quote

PARALLEL STRINGS – PARALLEL UNIVERSES

The absence of any theoretical limitation to the number of parallel strings is borne out by the experience of telecom operators, and at least one battery manufacturer allows up to 16 parallel

Get a quote

What Voltage is Too Low for a Lithium Battery?

Modern lithium batteries contain multiple protection layers, but voltage remains the primary health indicator. We''ve tested 2,000+ cells and found that just three discharges to

Get a quote

Battery Cell Balancing: What to Balance and How

V=OCV(SOC) + I • R(SOC) (considering that discharge current is negative). Because function R(SOC) is rapidly increasing its value at low SOC values, the voltage differences between the

Get a quote

A minor-fault diagnosis approach based on modified variance for

By calculating the modified variance of each battery voltage sequence in the lithium-ion battery strings online, the proposed approach is able to efficiently diagnose the initial minor

Get a quote

Cell-balancing currents in parallel strings of a battery system

Reliability and safety are important and timely issues for lithium-ion batteries [1] that shall be addressed by stakeholders in all sectors where large battery packs are required to

Get a quote

Best String Trimmers Battery [Updated On: September 2025]

10 hours ago· When consulting with landscapers and DIYers about their best string trimmers battery needs, one thing keeps coming up—power, reliability, and ease of use.

Get a quote

The Comprehensive Guide to LiFePO4 Voltage Chart

Understanding the voltage characteristics of these batteries is crucial for their optimal performance and longevity. In this comprehensive guide, we''ll delve into the specifics of

Get a quote

Common Lithium-ion Battery Problems and How to

Root cause 1: High self-discharge, which causes low voltage. Solution: Charge the bare lithium battery directly using the charger with over

Get a quote

How to Solve the Imbalance between Li-ion Battery

Here are 4 steps to solve the Imbalance between the Li-ion battery pack cells which will shorten the battery pack''s service life if not dealt with in

Get a quote

Improved voltage transfer method for lithium battery string

Furthermore, analysis of 50 samples shows that the improved method can greatly eliminate the battery leakage. The circuit reduces the leakage current to nanoampere scale

Get a quote

What voltage is too low for lithium battery?

The critical low-voltage threshold for lithium-ion batteries is 2.5V per cell, below which irreversible damage occurs due to copper dissolution and SEI layer breakdown. Discharging below

Get a quote

Common Lithium-ion Battery Problems and How to Fix Them

Root cause 1: High self-discharge, which causes low voltage. Solution: Charge the bare lithium battery directly using the charger with over-voltage protection, but do not use

Get a quote

Battery Voltage Chart (12V/24V/48V) | Sungold

Battery Voltage Chart: 12V/24V/48V quick guides for LiFePO4 & AGM—measurement best practices, SOC estimation, and RV/off-grid charging settings with

Get a quote

6 FAQs about [The voltage of one of the lithium battery strings is low]

What causes low voltage in a lithium battery?

Root cause 1: High self-discharge, which causes low voltage. Solution: Charge the bare lithium battery directly using the charger with over-voltage protection, but do not use universal charge. It could be quite dangerous. Root cause 2: Uneven current.

Can a lithium ion battery pack have multiple strings?

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However, sometimes it may be necessary to use multiple strings of cells. Here are a few reasons that parallel strings may be necessary:

What happens if battery voltage is below 2V?

If the voltage is below 2V, the internal structure of lithium battery will be damaged, and the battery life will be affected. Root cause 1: High self-discharge, which causes low voltage. Solution: Charge the bare lithium battery directly using the charger with over-voltage protection, but do not use universal charge. It could be quite dangerous.

What happens if a Li-ion cell is discharged under a minimum voltage?

If discharged under this voltage, the cell may be permanently damaged. To get the precise value of min discharge voltage, consult the datasheet of your cell. This requires an update in 2020: For most modern Li-ion cells, 2.5 V is the discharge limit.

How to charge a bare lithium battery?

Solution: Charge the bare lithium battery directly using the charger with over-voltage protection, but do not use universal charge. It could be quite dangerous. Root cause 2: Uneven current. Due to contact resistance or detection of charge, the current is inconsistent caused by the uneven charge of the cell.

How much voltage does a Li ion cell have?

Even worse, assuming that you measured 2.5 V at no load, your cells have dropped even lower when they were being discharged and have subsequently rebounded to 2.5 V after the load was removed. Li-ion cells have a maximum voltage of 4.2 V or less, I am not sure where you got the 4.7 V figure from but it's a recipe for fireworks.

Guess what you want to know

-

Does it need to balance the voltage when making a lithium battery pack

Does it need to balance the voltage when making a lithium battery pack

-

Lithium battery pack voltage type

Lithium battery pack voltage type

-

Canadian low temperature lithium battery pack supplier

Canadian low temperature lithium battery pack supplier

-

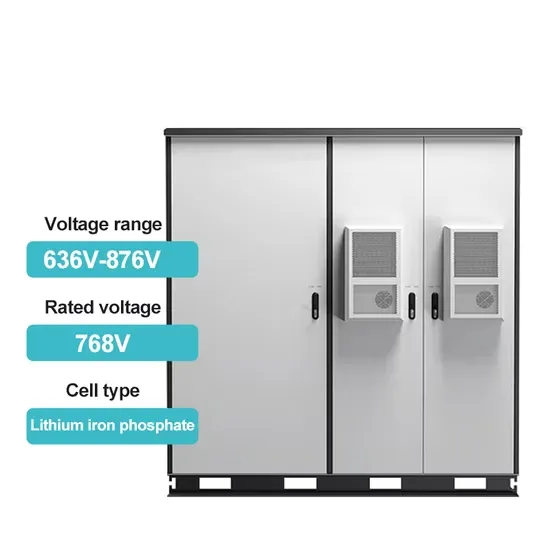

Is the voltage of the energy storage lithium battery system high

Is the voltage of the energy storage lithium battery system high

-

Ethiopia energy storage low temperature lithium battery

Ethiopia energy storage low temperature lithium battery

-

12v lithium battery pack output voltage

12v lithium battery pack output voltage

-

Lithium battery pack capacity normal voltage high

Lithium battery pack capacity normal voltage high

-

Static voltage of lithium battery pack when fully charged

Static voltage of lithium battery pack when fully charged

-

Guyana energy storage low temperature lithium battery

Guyana energy storage low temperature lithium battery

-

13 lithium battery pack voltage is different

13 lithium battery pack voltage is different

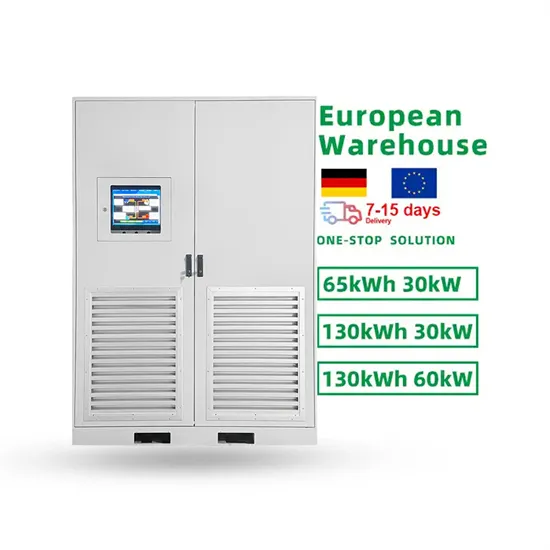

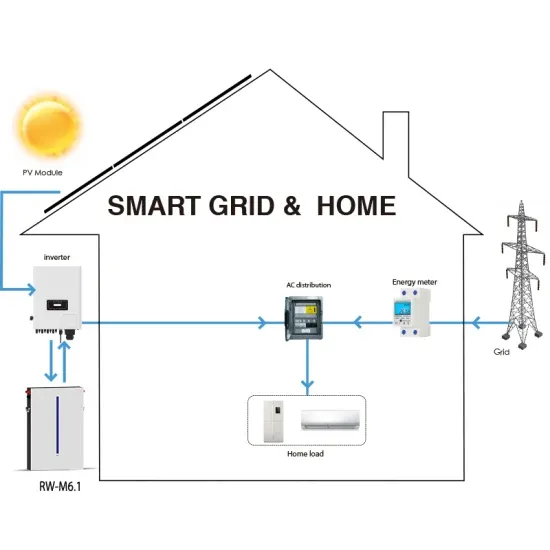

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.