Machines for entire solar panel recycling process

Our equipment can quickly and effectively recycle and reuse end-of-life solar PV panels, if you have any questions or need more information,

Get a quote

Solar Panel Recycle Plant Hot Best Seller for Crushing and Sorting

China Solar Panel Recycle Plant Hot Best Seller for Crushing and Sorting Equipment, Find details about China Solar Panel Recycling Machine from Solar Panel Recycle Plant Hot Best Seller

Get a quote

Solar Panel Recycling Plant

Aluminum frame removing machine: Removing the aluminum frame at the edge of the solar panel. Crushing and sorting machines: The treated solar panels then pass through the crushing and

Get a quote

Do PV Panel Recycling Plants Need Shredding Equipment?

The global solar energy boom has created a pressing need for efficient photovoltaic (PV) panel recycling. But do recycling plants really need specialized shredding

Get a quote

Inspection and monitoring for PV wafer & cell

Cell sorting at the end of the line is mandatory for high-value modules of homogenous color. The CELL-Q inline inspection system checks the front or

Get a quote

Air Flow Specific Gravity Sorting Equipment

Airflow-specific gravity sorting equipment is a high-efficiency equipment that utilizes the difference in specific gravity of materials and sorts them under airflow. By adjusting the

Get a quote

Air flow specific gravity sorting equipment

Air flow sorting machine (specific gravity sorter) is suitable for all kinds of metal and non-metal separation, powder materials, granular

Get a quote

High Sorting Rate Manufacturing Recycling Plant Solar Panel

The waste solar panel recycling equipment can efficiently dismantle solar panels, first remove the aluminum frame, and then separate the glass; then separate silicon powder, EVA glue, iron,

Get a quote

What are the equipment for recycling, crushing, and sorting waste

The recycling, crushing, and sorting line for waste solar panels usually consists of crushing equipment, sorting equipment, auxiliary equipment, and control systems.

Get a quote

What Equipment Is Available For Dismantling Solar PV Panels?

Solar photovoltaic panel module dismantling equipment is an indispensable equipment in the photovoltaic industry. The waste PV modules are dismantled, crushed and

Get a quote

Solar PV End-of-Life Waste Recycling: An

This research article investigates the recycling of end-of-life solar photovoltaic (PV) panels by analyzing various mechanical methods, including

Get a quote

Solar panel dismantling, crushing sorting and recycling machine

Effective recycling and disposal of solar panels at the end of their life becomes especially important. Below is information about solar panel dismantling, shredding, sorting,

Get a quote

Equipment for Recycling of Solar Panels | SUNY GROUP

Solar panel recycling is usually divided into several main stages: preliminary disassembly and classification, crushing and material separation, waste treatment, and

Get a quote

Solar Panel Recycling Machine & Equipment Manufacturer

Professional manufacturer of solar panel recycling machines and equipment. We provide complete solutions for PV panel dismantling, material separation, and eco-friendly waste

Get a quote

Solar Panel Recycling Plant Waste Solar Panel Frame And

Solar Panel Recycling Plant Waste Solar Panel Frame And Photovoltaic Cell Sheet Separating Machine PV Module Sorting Equipment

Get a quote

What equipment can recycle waste photovotaic panels

Setting up a PV panel recycling facility requires a robust array of specialized equipment tailored to handle the complex materials found in these panels. Below, we outline

Get a quote

Fully Automatic Solar Panel Separation and Recycling Line

As the number of scrapped photovoltaic panels continues to grow. To solve the problem of photovoltaic module recycling, HENAN RECYCLE has launched a fully automatic

Get a quote

Key Screening Equipment in Photovoltaic Panel Recycling Lines

To achieve this, specialized screening and sorting equipment plays a vital role in ensuring efficiency and material purity. Below, we explore the key types of equipment used in

Get a quote

SPR launches automated bifacial solar panel recycling line

SPR launches automated bifacial solar panel recycling line The company says its new line enables clean glass separation of bifacial modules at recovery rates of 99 percent or

Get a quote

Solar panel dismantling, crushing sorting and

Effective recycling and disposal of solar panels at the end of their life becomes especially important. Below is information about solar panel

Get a quote

How much does a solar-powered garbage sorting room cost?

In essence, a solar-powered garbage sorting room utilizes solar panels to generate energy that powers the sorting equipment and other related operations. This approach

Get a quote

What are the equipment for recycling, crushing, and sorting waste solar

The recycling, crushing, and sorting line for waste solar panels usually consists of crushing equipment, sorting equipment, auxiliary equipment, and control systems.

Get a quote

What Materials Can be Recycled from Solar Panels?

They can handle a large number of panels per hour, preparing the panels for further material recovery. B. Cell Separation Equipment After

Get a quote

Machines for entire solar panel recycling process

Our equipment can quickly and effectively recycle and reuse end-of-life solar PV panels, if you have any questions or need more information, please feel free to contact us.

Get a quote

For European Market Solar Panel Recycling Production Line

High-Capacity Shredding & Sorting: Equipped with crushers, grinders, and automated sorting systems to process solar panel scrap into recyclable materials (metals, glass, plastics) with

Get a quote

Mechanical crushing method for separation and recycling of waste

The mechanical crushing method for separating and recycling waste photovoltaic panel equipment mainly relies on physical cutting, hammering, extrusion and grinding to break

Get a quote

Guess what you want to know

-

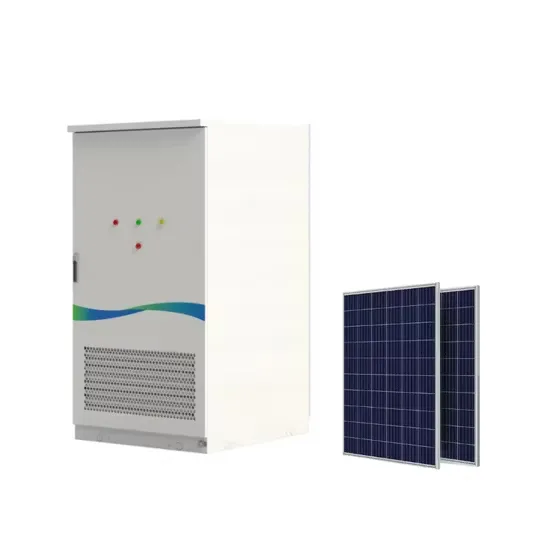

Outdoor solar panel power storage equipment

Outdoor solar panel power storage equipment

-

Photovoltaic equipment solar panel matching

Photovoltaic equipment solar panel matching

-

Solar panel lightweight equipment

Solar panel lightweight equipment

-

Photovoltaic panel single wave solar panel removal equipment

Photovoltaic panel single wave solar panel removal equipment

-

Mexican solar panel equipment

Mexican solar panel equipment

-

North Korean solar photovoltaic panel production equipment manufacturer

North Korean solar photovoltaic panel production equipment manufacturer

-

Photovoltaic panels to solar panel equipment

Photovoltaic panels to solar panel equipment

-

How much does solar photovoltaic silicon panel equipment cost

How much does solar photovoltaic silicon panel equipment cost

-

Solar thermal equipment for communication base station solar panel factory

Solar thermal equipment for communication base station solar panel factory

-

Solar panel factory production equipment installation

Solar panel factory production equipment installation

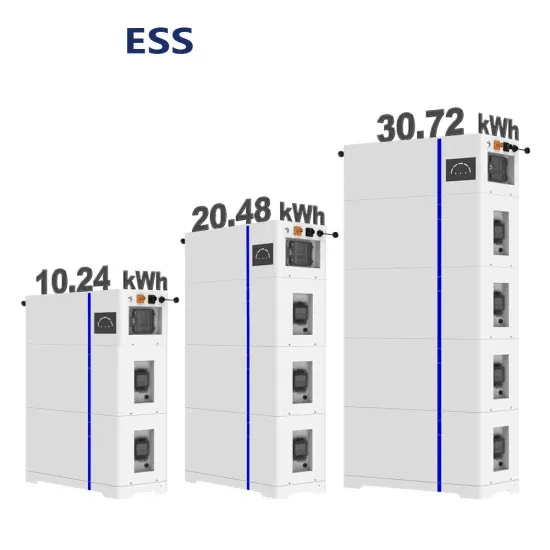

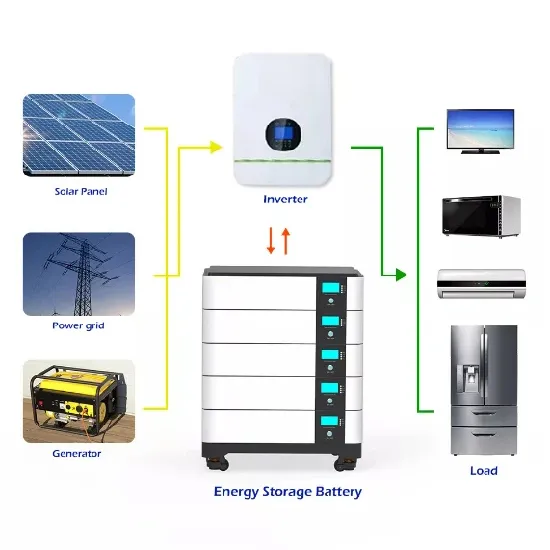

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

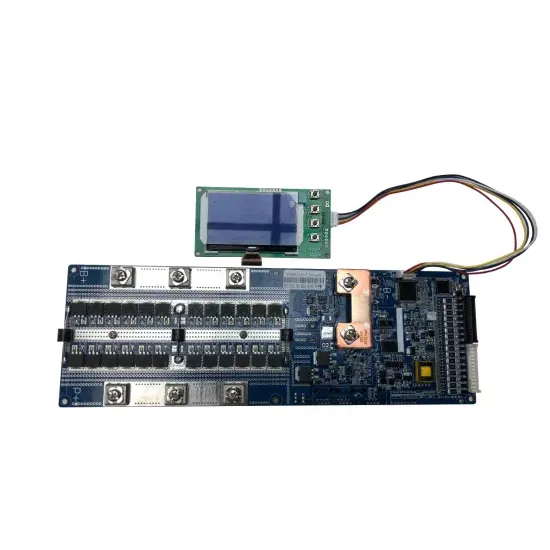

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.