Solar Photovoltaic System Cost Benchmarks

Market analysts routinely monitor and report the average cost of PV systems and components, but more detail is needed to understand the impact of recent and

Get a quote

Cost Breakdown of a Solar Panel: From Manufacturing to Market

This article delves into the comprehensive cost breakdown of solar panels, exploring the various facets of manufacturing costs, marketing and distribution expenses,

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled.

Get a quote

Solar Panel Manufacturing Plant Setup Cost 2025

IMARC Group''s report on solar panel manufacturing plant project provides detailed insights into business plan, setup, cost and requirements.

Get a quote

Solar PV Module Manufacturing Cost Analysis | Case Study

Looking ahead, the market is expected to grow at a CAGR of approximately 14.36% from 2025 to 2033, reaching a projected capacity of 4,919.2 TWh by 2033. A number of important factors

Get a quote

Solar PV Module Manufacturing Cost Analysis | Case

Looking ahead, the market is expected to grow at a CAGR of approximately 14.36% from 2025 to 2033, reaching a projected capacity of 4,919.2 TWh by

Get a quote

Solar Photovoltaic System Cost Benchmarks

Market analysts routinely monitor and report the average cost of PV systems and components, but more detail is needed to understand the impact of recent and future technology

Get a quote

How Much Does it Cost to Make a Solar Panel

Uncover the details on ''how much does it cost to make a solar panel'' in our comprehensive guide. Learn all about solar panel production costs.

Get a quote

Solar Panel Cost In 2025: It May Be Lower Than You

It costs about $28,000 to install solar panels. That''s a big number, but it can come down significantly with generous incentives from the federal

Get a quote

Solar (photovoltaic) panel prices

IRENA presents solar photovoltaic module prices for a number of different technologies. Here we use the average yearly price for technologies ''Thin film a-Si/u-Si or

Get a quote

How Much Do Solar Panels Cost in 2025? Everything

Solar panels can save you money on your electricity bills, but how much do they cost, and are they worth the investment? Read below to know.

Get a quote

How Much Does Solar Installation Cost? Price Guide for 2024

The cost of solar panels depends on the solar panel company you choose. This encompasses the solar equipment system itself, installation costs, and any additional features.

Get a quote

How Much Does it Cost to Produce Solar Panels and Modules

Uncover solar panel manufacturing processes and expenses, discover what technological advancements make a difference, and learn how the costs can be reduced in

Get a quote

Crystalline Silicon Photovoltaic Module Manufacturing Costs

Executive Summary Over the past decade, the crystalline-silicon (c-Si) photovoltaic (PV) industry has grown rapidly and developed a truly global supply chain, driven by increasing consumer

Get a quote

Solar Panel Manufacturing Cost: A Complete Factory Breakdown

Starting a solar panel factory? Get a detailed cost breakdown for machinery, buildings, and working capital for 25 MW, 100 MW, and 800 MW production lines.

Get a quote

Solar Technology Cost Analysis | Solar Market

NREL''s solar technology cost analysis examines the technology costs and supply chain issues for solar photovoltaic (PV) technologies. This

Get a quote

Solar panels per m² costs

How do solar panels work? Solar panels use the light from the sun to generate energy. The panels do not need to be in the sun all day to be profitable, although this does provide more

Get a quote

How much does a photovoltaic solar panel cost per

Determining the cost of photovoltaic solar panels per square meter is essential for evaluating the overall investment in solar energy systems. 1.

Get a quote

Solar Technology Cost Analysis | Solar Market Research & Analysis | NREL

NREL''s solar technology cost analysis examines the technology costs and supply chain issues for solar photovoltaic (PV) technologies. This work informs research and

Get a quote

How much does it cost to make solar panel equipment?

The cost of solar panel manufacturing originates from various elements, including raw materials, labor, equipment, and overhead expenses. Raw materials such as silicon,

Get a quote

Solar Manufacturing Cost Analysis | Solar Market Research & Analysis | NREL

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are

Get a quote

How much does a home photovoltaic solar panel cost?

How much does a home photovoltaic solar panel cost? The expense associated with the installation of photovoltaic solar panels for residential properties varies significantly,

Get a quote

How much does it cost to physically recycle photovoltaic panels?

This type of equipment separates materials based on their electrical conductivity. For example, it can separate glass from silicon and metals in the shredded PV panel

Get a quote

Cost Breakdown of a Solar Panel: From

This article delves into the comprehensive cost breakdown of solar panels, exploring the various facets of manufacturing costs, marketing and

Get a quote

How much does it cost to make solar panel equipment?

The cost of solar panel manufacturing originates from various elements, including raw materials, labor, equipment, and overhead expenses.

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar Photovoltaic Manufacturing Basics Solar manufacturing encompasses the production of products and materials across the solar value chain. While some

Get a quote

U.S. Solar Photovoltaic System and Energy Storage Cost

We obtain most of the specific cost inputs (material costs, component and subcomponent costs, installation rental equipment rates, and labor rates) from sources such as RSMeans, the U.S.

Get a quote

Average Cost of Solar Panels for Homes (2024)

Learn the average cost of solar panels, including a pricing breakdown between hard costs like materials and soft costs like installation

Get a quote

6 FAQs about [How much does solar photovoltaic silicon panel equipment cost ]

How much money do you need to produce solar panels?

To ensure you have enough stock to avoid stopping production due to a lack of materials, you should estimate approximately €6.5 million for working capital, including materials in stock. The cost of materials for solar panels constitutes over 95% of the total production costs, making it the dominant factor in solar module production.

How much does a solar panel cost?

The cost to manufacture a solar panel can vary greatly depending on the type and size, but it generally ranges from $0.70 to $1 per watt. Therefore, a solar panel with a capacity of 250 watts might cost between $175 and $250 to produce. It’s important to note this does not include marketing, shipping, or installation costs.

What is NREL analysis of manufacturing costs for silicon solar cells?

NREL analysis of manufacturing costs for silicon solar cells includes bottom-up cost modeling for all the steps in the silicon value chain. Solar Manufacturing Cost Analysis Solar Installed System Cost Analysis Solar Levelized Cost of Energy Analysis Solar Supply Chain and Industry Analysis Solar System Operations and Maintenance Analysis

How can solar energy be made more affordable?

Manufacturing Innovations: New manufacturing techniques that streamline production processes or utilize less expensive materials can lower the cost of solar panels, making solar energy more accessible.

How are PV production costs modeled?

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

How did our solar PV module manufacturing plant's financial model work?

Our solar PV module manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs.

Guess what you want to know

-

How much does solar photovoltaic panel equipment cost

How much does solar photovoltaic panel equipment cost

-

How many watts does a 300W solar photovoltaic panel cost

How many watts does a 300W solar photovoltaic panel cost

-

How much does a photovoltaic solar panel cost per square meter

How much does a photovoltaic solar panel cost per square meter

-

How much does a 200kw photovoltaic panel cost per square meter

How much does a 200kw photovoltaic panel cost per square meter

-

Photovoltaic equipment solar panel matching

Photovoltaic equipment solar panel matching

-

How many solar panels are needed for a photovoltaic panel

How many solar panels are needed for a photovoltaic panel

-

How big a solar panel does a 1kW photovoltaic inverter require

How big a solar panel does a 1kW photovoltaic inverter require

-

How much does a 268 watt solar panel cost

How much does a 268 watt solar panel cost

-

How much does solar photovoltaic panels cost in South Africa

How much does solar photovoltaic panels cost in South Africa

-

How much electricity can a monocrystalline silicon photovoltaic panel generate

How much electricity can a monocrystalline silicon photovoltaic panel generate

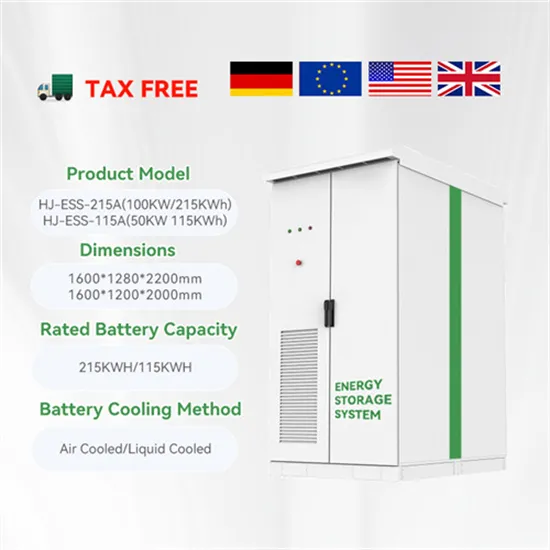

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.