From communication base station to emergency power supply lead-acid

Lead-acid batteries have built a solid power guarantee network in the field of communication base stations and emergency power supplies by virtue of their stability, reliability, adaptability to the

Get a quote

Maintenance and care of lead-acid battery packs for solar communication

The battery pack is an important component of the base station to achieve uninterrupted DC power supply, and its investment amount is b asic ally equivalent to that of the rack power

Get a quote

Maintenance and care of lead-acid battery packs for solar communication

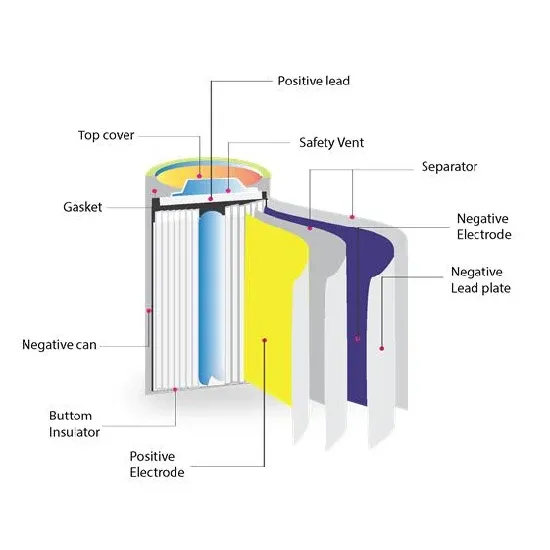

Due to the use of a valve-controlled sealed structure, there is no need to add acid or water for maintenance, no acid liquid or acid mist leaks, and it can be placed in the same machine room

Get a quote

Battery for Communication Base Stations Market | Size & Share

One of the key trends shaping the communication base station battery market is the shift towards lithium-ion batteries from traditional lead-acid batteries. Lithium-ion batteries offer higher

Get a quote

Maintenance of lead-acid batteries for communication base stations

Abstract: Lead-acid batteries are widely used in substations, communication base stations, electric vehicles, solar energy, wind energy and other fields. However, due to improper daily

Get a quote

Environmental feasibility of secondary use of electric vehicle

Life cycle assessment (LCA) is used in this study to compare the environmental impacts of repurposed EV LIBs and lead-acid batteries (LABs) used in conventional energy

Get a quote

TITLE: ESOP 9.8| MANAGEMENT AND STORAGE OF

Damaged communication batteries will be segregated from other batteries and will be identified to the EMD/RCRS staff as damaged during the unit''s regularly scheduled Curbside Service...

Get a quote

Maintenance and care of lead-acid battery packs for solar communication

The battery pack is an important component of the base station to achieve uninterrupted DC power supply. Its investment is basically the same as that of the rack power supply equipment.

Get a quote

Memorandum: Lead Acid Battery Reporting Under EPCRA

Questions have been raised recently about how to calculate the threshold and to report lead acid batteries under Sections 311 and 312 of the Emergency Planning and Community Right-to

Get a quote

Solar Powered Cellular Base Stations: Current Scenario, Issues

Cellular base stations powered by renewable energy sources such as solar power have emerged as one of the promising solutions to these issues.

Get a quote

What is a base station energy storage battery?

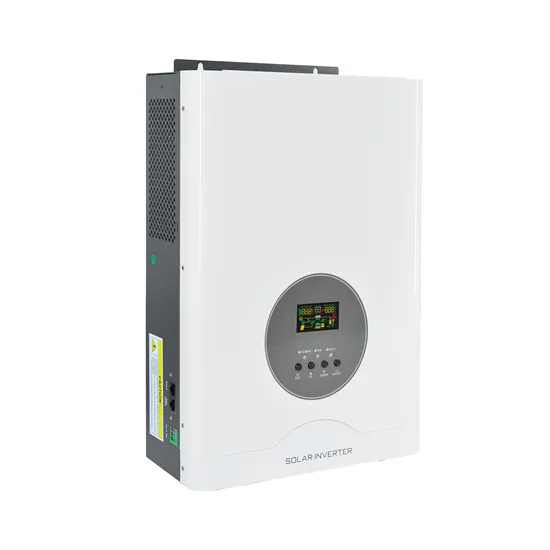

A base station energy storage battery is a crucial component of telecommunication infrastructure, designed to improve the efficiency and

Get a quote

IEEE Recommended Practice for Maintenance, Testing, and

The purpose of this recommended practice is to provide the user with information and recommendations concerning the maintenance, testing, and replacement of vented lead-acid

Get a quote

Final

However, the operation of certain types of switching and transmitting equipment may require the use backup power systems consisting of a combination of batteries (typically lead-acid

Get a quote

Battery Room Ventilation and Safety

BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms must be adequately

Get a quote

From communication base station to emergency

Lead-acid batteries have built a solid power guarantee network in the field of communication base stations and emergency power supplies by virtue of their

Get a quote

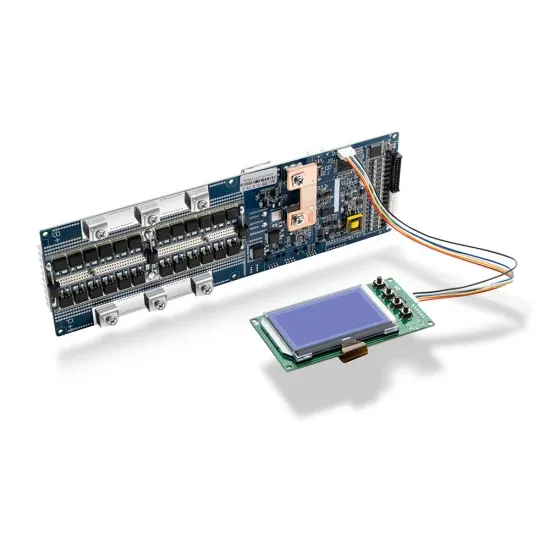

What to Know About OEM Rack-Mounted Lithium Batteries for Telecom Base

OEM rack-mounted lithium batteries are crucial for powering telecom base stations, providing reliable and efficient energy solutions. These batteries are designed to

Get a quote

Environmental Standard Operating Procedure Battery

This guidance applies to individuals working with the recharging, replacement, and disposal of communications, electronic, and lead acid batteries aboard MCLB Barstow.

Get a quote

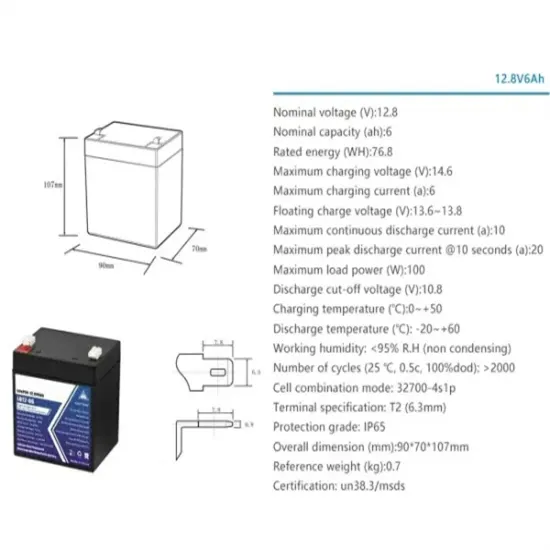

The 200Ah Communication Base Station Backup

GEM Battery GF series communication base station lead-acid batteries are used for telecom communication backup power supply, support multi-channel

Get a quote

Maintenance and care of lead-acid battery packs for solar

Due to the use of a valve-controlled sealed structure, there is no need to add acid or water for maintenance, no acid liquid or acid mist leaks, and it can be placed in the same machine room

Get a quote

Comparative Carbon Footprint and Environmental Impacts of

LIBs have a lower carbon footprint and environmental impact than lead-acid and nickel-cadmium batteries [11, 12]. At the same time, the carbon footprint of LIBs during the

Get a quote

Study on the Environmental Risk Assessment of Lead-Acid Batteries

By analysing the environmental risk assessment of lead-acid batteries, the study supplied direction for the preventive measures according to the forecast results of lead-acid

Get a quote

Environmental feasibility of secondary use of electric vehicle

Repurposing spent batteries in communication base stations (CBSs) is a promising option to dispose massive spent lithium-ion batteries (LIBs) from electric vehicles (EVs), yet

Get a quote

What Batteries Are Used in Telecom Towers?

Why Use Lithium Batteries For Telecom Towers? Lithium batteries are used because they offer high energy density, longer lifespan, faster charging, and lower

Get a quote

6 FAQs about [Environmental inspection of lead-acid batteries in communication base stations]

Can a facility report lead acid batteries?

Once the facility determines it needs to report the batteries, it has two primary choices under the regulations regarding the manner in which it reports. The facility may either list the sulfuric acid separately on the Tier II form or it may list the lead acid batteries, indicating that sulfuric acid, an EHS, is a component of the mixture.

Is a lead acid battery a mixture?

Under EPCRA sections 311 and 312, a lead acid battery would be considered a mixture, containing both sulfuric acid, an extremely hazardous substance (EHS), and other hazardous chemicals such as lead, lead oxide, and lead sulfate.

How do you report lead acid batteries?

Instead, the facility has two options. In the first option, the owner or operator would add the total weight of the lead acid batteries and if the reporting threshold has been met (which is 10,000 pounds for non-EHS hazardous chemicals), would report the lead acid batteries.

What are the annexes of a lead-acid battery inspection program?

Annex E describes the visual inspection requirements. Annex F provides methods for measuring connection resistances. Annex G discusses alternative test and inspection programs. Annex H describes the effects of elevated temperature on lead-acid batteries. Annex I provides methodologies for conducting a modified performance test.

Do lead acid batteries fall under the article exemption?

Furthermore, OSHA's Directive on Inspection Procedures for the Hazard Communication Standard (CPL 02-02-038, March 20, 1998), states that lead acid batteries do not fall under the article exemption because they have the potential to leak, spill, or break during normal conditions of use, including foreseeable emergencies.

Does a lead acid battery contain sulfuric acid?

Since a lead acid battery contains sulfuric acid, an EHS, the regulations at 40 CFR § 370.28 require an owner or operator of a facility to aggregate the sulfuric acid present in all lead acid batteries as well as in any other mixture or in pure form at the facility, in order to determine if the threshold has been met or exceeded.

Guess what you want to know

-

Main equipment cost of lead-acid batteries for communication base stations

Main equipment cost of lead-acid batteries for communication base stations

-

How many lead-acid batteries are there in China s communication base stations

How many lead-acid batteries are there in China s communication base stations

-

Do communication base stations still use lead-acid batteries

Do communication base stations still use lead-acid batteries

-

Construction cost of lead-acid batteries for communication base stations in the UAE

Construction cost of lead-acid batteries for communication base stations in the UAE

-

How many lead-acid batteries are there in Comoros 5G communication base stations

How many lead-acid batteries are there in Comoros 5G communication base stations

-

Where are the lead-acid batteries for communication base stations in Uzbekistan

Where are the lead-acid batteries for communication base stations in Uzbekistan

-

The latest planning of lead-acid batteries for Cyprus communication base stations

The latest planning of lead-acid batteries for Cyprus communication base stations

-

Do communication network base stations have batteries

Do communication network base stations have batteries

-

The role of lead-acid battery equipment in communication base stations

The role of lead-acid battery equipment in communication base stations

-

Can sodium ion batteries be used in communication base stations

Can sodium ion batteries be used in communication base stations

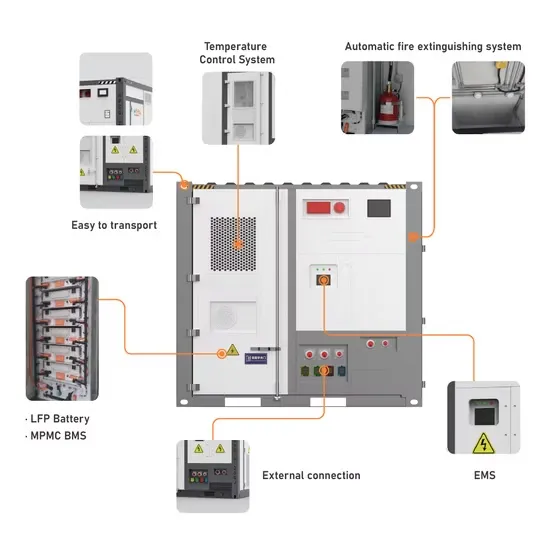

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.