Flywheel Energy Storage Systems | Electricity

A flywheel is a mechanical device that stores energy by spinning a rotor at very high speeds. The basic concept involves converting electrical energy into

Get a quote

WhitePaper-Safety of Flywheel Storages Systems

This paper describes safety principles for the safe operation of commercial flywheel systems. Information is taken from analyst reports on various events which have occurred (9) and the

Get a quote

Flywheels | Climate Technology Centre & Network | Tue, 11/08/2016

Components of a flywheel energy storage system A flywheel has several critical components. a) Rotor – a spinning mass that stores energy in the form of momentum (EPRI, 2002) The rotor,

Get a quote

Flywheel Energy Storage Safety: What You Need to Know

Who Cares About Flywheel Safety? (And Why You Should Too) when most people hear "flywheel energy storage," they either picture giant hamster wheels or that scene from

Get a quote

Recommended Practices for the Safe Design and Operation

This protocol is intended to establish design criteria and test procedures applicable to mechanical energy storage systems for the purpose of verifying and documenting the safety of these

Get a quote

Grid-Scale Flywheel Energy Storage Plant

Flywheel systems are kinetic energy storage devices that react instantly when needed. By accelerating a cylindrical rotor (flywheel) to a very high speed and maintaining the energy in

Get a quote

(PDF) Design and Analysis of Flywheel for Different

The flywheel is the simplest device for mechanical battery that can charge/discharge electricity by converting it into the kinetic energy of a rotating

Get a quote

Flywheel Energy Storage Systems | Electricity Storage Units

A flywheel is a mechanical device that stores energy by spinning a rotor at very high speeds. The basic concept involves converting electrical energy into rotational energy, storing it, and then

Get a quote

Flywheel Energy Storage Housing | SpringerLink

In this case, the flywheel energy storage unit may be destroyed, but of course no fragments should escape from the safety housing and thus represent a further risk of injury.

Get a quote

Flywheel Energy Storage Safety: What You Need to Know

This article cuts through the spin (pun intended) to explore why these mechanical batteries could revolutionize energy storage - if we keep them from becoming high-speed

Get a quote

Energy storage devices in electrified railway systems: A review

Generally, a flywheel energy storage system (FESS) contains four key components: a rotor, a rotor bearing, an electrical machine and a power electronics interface [12].

Get a quote

Flywheel Energy Storage Housing | SpringerLink

The housing of a flywheel energy storage system (FESS) also serves as a burst containment in the case of rotor failure of vehicle crash. In this chapter, the requirements for

Get a quote

Flywheel Energy Storage System

The entire flywheel energy storage system realizes the input, storage, and output processes of electrical energy. The flywheel battery system includes a motor, which operates in the form of

Get a quote

Flywheel Energy Storage System: What Is It and How

In essence, a flywheel stores and releases energy just like a figure skater harnessing and controlling their spinning momentum, offering fast, efficient,

Get a quote

Flywheel Systems for Utility Scale Energy Storage

More than 15 flywheel units have been tested with the fleet accumulating more than 38,000 hours of operating history. Numerous design and manufacturing enhancements emerged from this

Get a quote

DOE ESHB Chapter 7 Flywheels

A standalone flywheel developed expressly for energy storage will experience much longer charge and discharge intervals and may be operated over a speed range of greater than 2:1

Get a quote

The Status and Future of Flywheel Energy Storage: Joule

This concise treatise on electric flywheel energy storage describes the fundamentals underpinning the technology and system elements. Steel and composite rotors

Get a quote

Flywheel Energy Storage Systems | Electricity

RotorVault flywheel storage systems provide reliable energy storage solutions for residential, commercial and grid-scale applications worldwide.

Get a quote

(PDF) Safety of Flywheel Storage Systems

Robust system design, in combination with the use of certified critical materials, relevant quality control measures and documentation, are the basis for the construction of safe

Get a quote

Recommended Practices for the Safe Design and Operation of

This protocol recommends a technical basis for safe flywheel de sign and operation for consideration by flywheel developers, users of flywheel systems and standards setting

Get a quote

Designing Safer Energy Storage Flywheels

Another formidable technical challenge is designing a lightweight, cost-effective safety containment system that can resist the impact of burst fragments and transmission of high

Get a quote

The Status and Future of Flywheel Energy Storage

Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

Get a quote

Optimization strategy for braking energy recovery of electric

Abstract Braking energy recovery (BER) notably extends the range of electric vehicles (EVs), yet the high power it generates can diminish battery life. This paper proposes

Get a quote

6 FAQs about [Safe distance from flywheel energy storage]

Can flywheel energy storage be commercially viable?

This project explored flywheel energy storage R&D to reach commercial viability for utility scale energy storage. This required advancing the design, manufacturing capability, system cost, storage capacity, efficiency, reliability, safety, and system level operation of flywheel energy storage technology.

What makes a safe flywheel system?

Robust system design, in combination with the use of certified critical materials, relevant quality control measures and documentation, are the basis for the construction of safe flywheel systems. These can be certified by appropriate independent parties as in the manufacture of many other products.

Are energy storage flywheels dangerous?

Even though there are hardly any known accidents involving energy storage flywheels that actually resulted in personal injury, incidents such as the much-cited rotor burst in Beacon Power ’s grid stability plant in Stephentown are sufficient to fuel mistrust of FESS technology [ 1 ].

Is a flywheel energy storage system a burst containment?

The housing of a flywheel energy storage system (FESS) also serves as a burst containment in the case of rotor failure of vehicle crash. In this chapter, the requirements for this safety-critical component are discussed, followed by an analysis of historical and contemporary burst containment designs.

What is a flywheel energy storage system (fess)?

Flywheel Energy Storage Systems (FESS) play an important role in the energy storage business. Its ability to cycle and deliver high power, as well as, high power gradients makes them superior for storage applications such as frequency regulation, voltage support and power firming.

Are flywheels safe?

The safety design criteria were validated though a series of induced failures and overstress events. The flywheels were completely tolerant of a number of fault scenarios such as a loss of vacuum, loss of power, and overspeed; they survived these types of events without damage and were easily put back into service.

Guess what you want to know

-

Safe distance between energy storage battery compartments

Safe distance between energy storage battery compartments

-

Huawei develops flywheel energy storage

Huawei develops flywheel energy storage

-

British flywheel energy storage equipment

British flywheel energy storage equipment

-

Flywheel energy storage distributed power generation

Flywheel energy storage distributed power generation

-

Polish flywheel energy storage device

Polish flywheel energy storage device

-

Commercialization of flywheel energy storage

Commercialization of flywheel energy storage

-

Flywheel compression energy storage

Flywheel compression energy storage

-

When the flywheel energy storage is discharged the flywheel acts as

When the flywheel energy storage is discharged the flywheel acts as

-

Flywheel energy storage power characteristics

Flywheel energy storage power characteristics

-

Global Flywheel Energy Storage Power Station

Global Flywheel Energy Storage Power Station

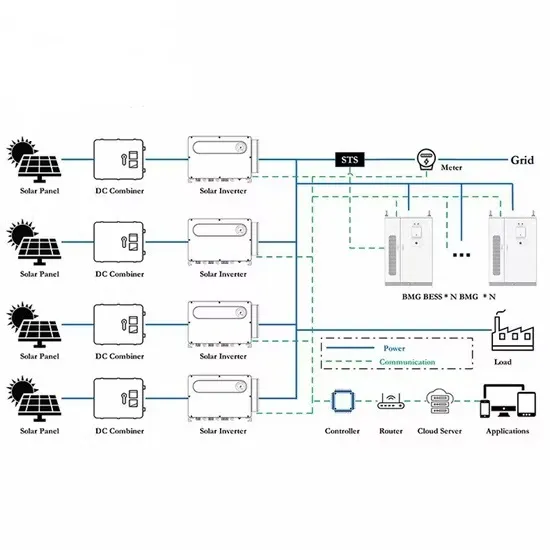

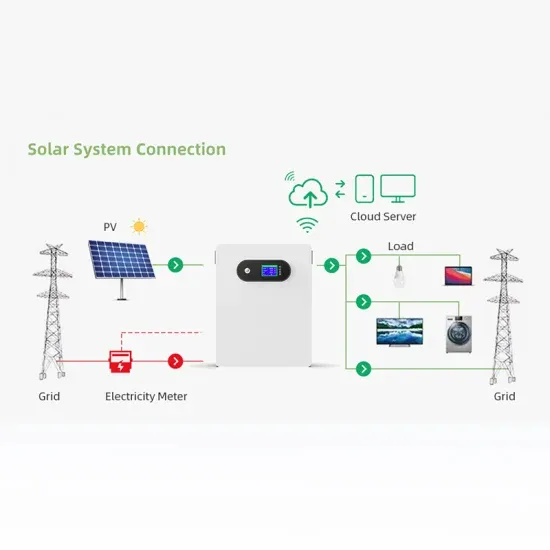

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.