What are the characteristics of flywheel energy storage?

Flywheel energy storage systems are distinguished by several key characteristics: 1. High power density; 2. Long cycle life; 3. Rapid response time; 4. Low main

Get a quote

Stability analysis of composite energy storage flywheel rotor

Composite flywheels are used in large-capacity flywheel energy storage due to their high strength and high energy storage density. We studied the instability of the composite

Get a quote

Technical characteristics of flywheel energy storage

teries Adv 9 1.3ypes of Lead-Acid Batteries T 10 Flywheel energy storage technology is an emerging energy storage technology that stores kinetic energy through a rotor that rotates at

Get a quote

An Overview of the R&D of Flywheel Energy Storage

The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

Get a quote

Flywheel Energy Storage System: What Is It and How Does It

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like composite carbon fiber, stores energy in

Get a quote

The most complete analysis of flywheel energy storage for new energy

Flywheel energy storage is an energy storage technology with high power density, high reliability, long life, and environmental friendliness. It is characterized by full magnetic

Get a quote

Flywheel energy storage

OverviewPhysical characteristicsMain componentsApplicationsComparison to electric batteriesSee alsoFurther readingExternal links

Compared with other ways to store electricity, FES systems have long lifetimes (lasting decades with little or no maintenance; full-cycle lifetimes quoted for flywheels range from in excess of 10, up to 10, cycles of use), high specific energy (100–130 W·h/kg, or 360–500 kJ/kg), and large maximum power output. The energy efficiency (ratio of energy out per energy in) of flywheels, also known as round-trip efficiency, can be as high as 90%. Typical capacities range from 3 kWh to 1

Get a quote

A review of flywheel energy storage systems: state of the art and

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Get a quote

A of the Application and Development of Energy Storage

Abstract: High power density, high efficiency and low loss are the characteristics of flywheel energy storage, which has broad application prospects in the field of rail transit. This paper

Get a quote

Dynamic characteristics analysis of energy storage flywheel

The air-gap eccentricity of motor rotor is a common fault of flywheel energy storage devices. Consequently, this paper takes a high-power energy stora

Get a quote

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get a quote

A review of flywheel energy storage systems: state of the art

Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Get a quote

Design optimization, construction, and testing of a hydraulic flywheel

The hydraulic flywheel accumulator is a dual domain energy storage system that leverages complimentary characteristics of each domain. The system involves rotating a

Get a quote

The most complete analysis of flywheel energy

Flywheel energy storage is an energy storage technology with high power density, high reliability, long life, and environmental friendliness. It

Get a quote

Flywheel Energy Storage: A High-Efficiency Solution

Flywheel energy storage is an exciting solution for efficient and sustainable energy management. This innovative technology offers high

Get a quote

Principles and application scenarios of flywheel

The flywheel energy storage has the characteristics of high power, fast response speed, and strong circulation ability. It can quickly and effectively perform

Get a quote

Dynamic characteristics of flywheel energy storage virtual

The flywheel energy storage virtual synchronous generator (VSG) has the ability to provide fast response and inertia support to improve the frequency characteristics of the power system.

Get a quote

What is flywheel energy storage technology | NenPower

Enhanced energy independence emerges as communities increasingly embrace sustainable practices, exemplifying the critical role of

Get a quote

Flywheel Energy Storage System: What Is It and How

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like

Get a quote

Dynamic characteristics of flywheel energy storage virtual

Dynamic characteristics of flywheel energy storage virtual synchronous machine and analysis of power system frequency improvement [J]. Energy Storage Science and Technology, 2023, 12

Get a quote

High-Speed Kinetic Energy Storage System Development and

Flywheel energy storage systems (FESSs) can reach much higher speeds with the development of technology. This is possible with the development of composite materials. In

Get a quote

A Review of Flywheel Energy Storage System Technologies

One such technology is flywheel energy storage systems (FESSs). Compared with other energy storage systems, FESSs offer numerous advantages, including a long lifespan,

Get a quote

State switch control of magnetically suspended flywheel energy storage

The magnetically suspended flywheel energy storage system (MS-FESS) is an energy storage equipment that accomplishes the bidirectional transfer between electric energy

Get a quote

Technology: Flywheel Energy Storage

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm.

Get a quote

What are the characteristics of flywheel energy storage?

Flywheel energy storage systems are distinguished by several key characteristics: 1. High power density; 2. Long cycle life; 3. Rapid response

Get a quote

Principles and application scenarios of flywheel energy storage

The flywheel energy storage has the characteristics of high power, fast response speed, and strong circulation ability. It can quickly and effectively perform active/reactive power

Get a quote

6 FAQs about [Flywheel energy storage power characteristics]

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

What is a flywheel energy storage system?

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher tensile strength than steel and can store much more energy for the same mass. To reduce friction, magnetic bearings are sometimes used instead of mechanical bearings.

What is the difference between a flywheel and a battery storage system?

Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure. Battery Storage is typically a better choice for long-term energy storage, such as for renewable energy systems (solar or wind) or home energy storage.

What type of motor is used in a flywheel energy storage system?

Permanent-Magnet Motors for Flywheel Energy Storage Systems The permanent-magnet synchronous motor (PMSM) and the permanent-magnet brushless direct current (BLDC) motor are the two primary types of PM motors used in FESSs. PM motors boast advantages such as high efficiency, power density, compactness, and suitability for high-speed operations.

How does a flywheel retain energy?

Energy Storage: The flywheel continues to spin at high speed, maintaining energy as long as friction and resistance are minimized. The longer it spins, the more energy it holds, similar to how the skater retains rotational energy as they keep spinning.

How does a flywheel work?

Here’s a breakdown of the process: Energy Absorption: When there’s surplus electricity, such as when the grid is overproducing energy, the system uses that excess power to accelerate the flywheel. This energy is stored as kinetic energy, much like how the figure skater speeds up their spin by pulling in their arms.

Guess what you want to know

-

Swaziland Flywheel Energy Storage Photovoltaic Power Generation Installation

Swaziland Flywheel Energy Storage Photovoltaic Power Generation Installation

-

How to replace flywheel energy storage wind power

How to replace flywheel energy storage wind power

-

Flywheel energy storage power is getting lower and lower

Flywheel energy storage power is getting lower and lower

-

Saudi Arabia Power Plant Flywheel Energy Storage Project

Saudi Arabia Power Plant Flywheel Energy Storage Project

-

Gravity flywheel inertial energy storage power generation

Gravity flywheel inertial energy storage power generation

-

Operational characteristics of energy storage power stations

Operational characteristics of energy storage power stations

-

Flywheel Energy Storage Power Supply

Flywheel Energy Storage Power Supply

-

Flywheel energy storage power generation can be connected to the grid

Flywheel energy storage power generation can be connected to the grid

-

Egypt s flywheel energy storage photovoltaic power generation efficiency

Egypt s flywheel energy storage photovoltaic power generation efficiency

-

Flywheel Energy Storage Power Station Topology

Flywheel Energy Storage Power Station Topology

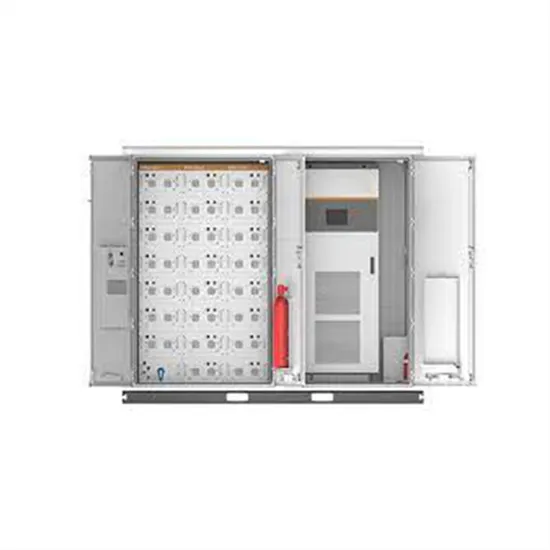

Industrial & Commercial Energy Storage Market Growth

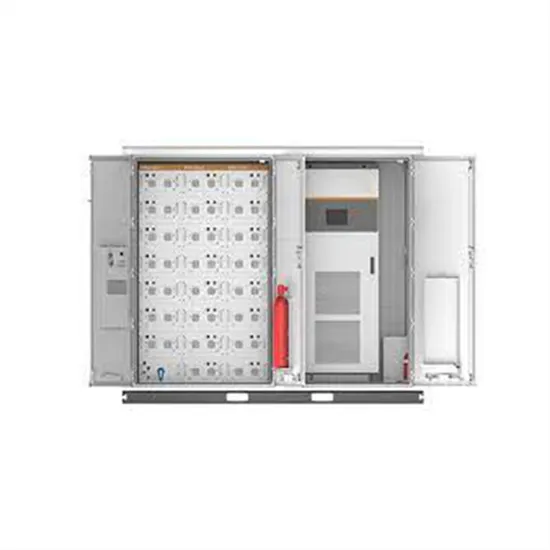

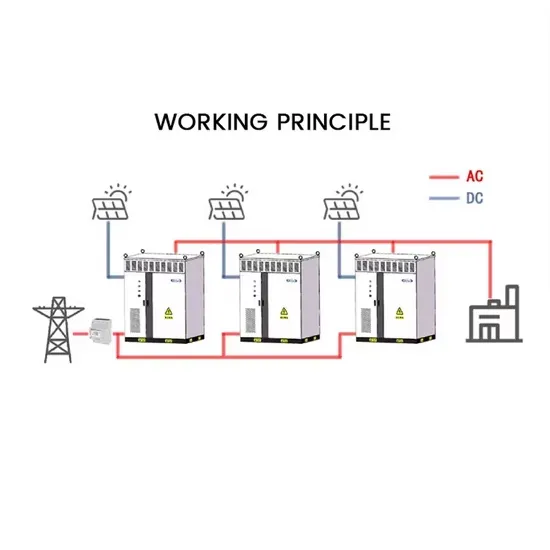

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

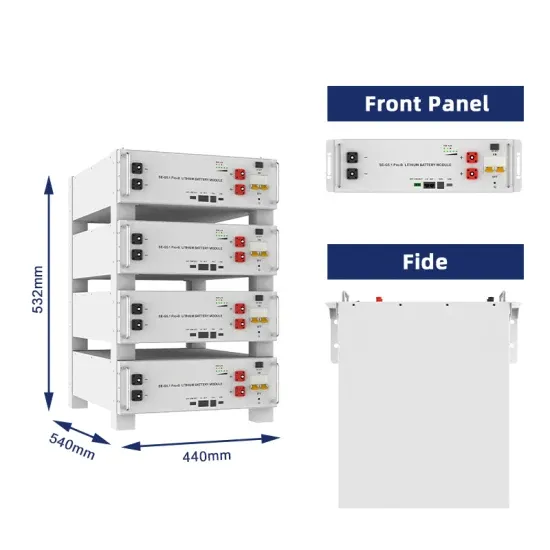

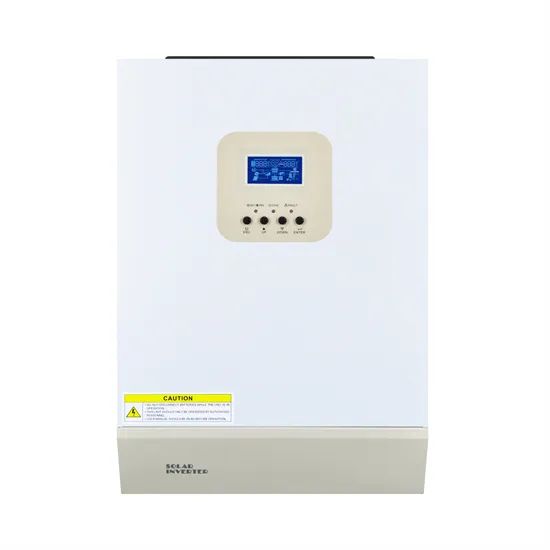

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.