Current Limiters in Grid-Forming Inverters: Challenges,

Current limiters are the first line of defense during grid disturbances. These devices regulate the flow of electrical current, ensuring it remains within safe operational limits. There

Get a quote

A Current Limiting Method with Distortion Suppression for Stand

Current limiting control is the key to continuous power supply of inverters. The inverters are generally switched to the current limiting mode to limit the fault currents when short-circuit

Get a quote

A Review of Current-Limiting Control of Grid-Forming Inverters

A Review of Current-Limiting Control of Grid-Forming Inverters Under Symmetrical Disturbances Published in: IEEE Open Journal of Power Electronics ( Volume: 3 )

Get a quote

PCS integration in Enphase Energy System Battery Power

Battery Power Limiting at Output of PV & Battery Connection (PoC): This is a PCS mode where the system was evaluated for its ability to control per-phase currents from the

Get a quote

A Review of Current-Limiting Control of Grid-Forming

To meet these requirements, various current-limiting con-trol methods for GFM inverters are reported in the literature, including current limiters, virtual impedance, and voltage lim-iters.

Get a quote

[2505.04177] Impact of Grid-Forming Inverters on Protective

Grid-forming (GFM) inverters can significantly alter the fault characteristics of power systems, which challenges the proper function of protective relays. This paper gives a holistic

Get a quote

Current limiting strategy for grid-connected inverters under

Grid-connected inverter plays an essential role as an interface between energy resources and the power grid. The performance of the inverters is adversely affected by the

Get a quote

Novel Hybrid Current Limiter for Grid-Forming Inverter

This paper proposes a novel current-limiting method for GFM inverters to handle unbalanced fault conditions while providing voltage support to the main grid.

Get a quote

A Current Limiting Control Strategy for Single-Loop Droop

Existing studies reporting current limiting control strategies for grid-forming inverters primarily focus on grid-forming inverters that use a multi-loop control structure. This study reports a

Get a quote

Current-Limiting Control of Grid-Forming Inverters: State-of-the

To protect the GFM inverters and support the power grid under faults or severe disturbances, various current-limiting control methods are developed. In this paper, an

Get a quote

Overcurrent Limiting in Grid-Forming Inverters: A Comprehensive

This article offers a comprehensive review of state-of-the-art current-limiting techniques for GFM inverters and outlines open challenges where innovative solutions are needed.

Get a quote

Power Limit Control Strategy for Household

The proposed strategy directly controls the inverter output current according to the power limit instructions from the electric operation control

Get a quote

Enhanced current-limiting droop controller for grid-connected

This is a repository copy of Enhanced current-limiting droop controller for grid-connected inverters to guarantee stability and maximize power injection under grid faults.

Get a quote

Current Limiters in Grid-Forming Inverters:

Current limiters are the first line of defense during grid disturbances. These devices regulate the flow of electrical current, ensuring it

Get a quote

Current Limiting Management in Grid Forming Inverter

In conclusion, this work has presented a comprehensive analysis of current limiting and power adjustment strategies for grid-forming inverters, particularly under fault conditions.

Get a quote

Control strategy for current limitation and maximum capacity

To provide over current limitation as well as to ensure maximum exploitation of the inverter capacity, a control strategy is proposed, and performance the strategy is evaluated based on

Get a quote

Current source inverter with grid forming control

In this work, grid forming control using a PWM-CSI is proposed and the control structure is presented. The inverter possesses excellent current limiting characteristics since

Get a quote

Best Grid Tie Inverter With Limiter: How It Works

The Limiter Sensor prevents excess current from flowing into the grid by limiting solar panel power generation. The inverter also includes high

Get a quote

Overcurrent Limiting in Grid-Forming Inverters: A

This includes methods that saturate the reference signal feeding into the inner-current control loop (current-reference saturation limiting) or control the inverter switch signals to promptly limit the

Get a quote

A Two-Stage Current Limiting Control Strategy for Direct-Droop

This paper presents a two-stage current limiting control strategy with fault ride-through capability for direct-droop-controlled grid-forming (GFM) inverters. The proposed two

Get a quote

Current limiting strategies for grid forming inverters under low

This work has carried out a comprehensive review of LVRT strategies for GFM inverters, focusing on those strategies that limit the current and enhance the transient stability,

Get a quote

Inverter Current Limiting Impacts on Power System Stability

device must be limited. These devices are easily damaged during over-current conditions and as a result, their steady state fault current contribution tends to be limited to around 1-1.3 pu,

Get a quote

Current-Limiting Control of Grid-Forming Inverters:

To protect the GFM inverters and support the power grid under faults or severe disturbances, various current-limiting control methods are

Get a quote

Control strategy for current limitation and maximum

To provide over current limitation as well as to ensure maximum exploitation of the inverter capacity, a control strategy is proposed, and performance the

Get a quote

6 FAQs about [Battery inverter current limiting control]

How do inverter current limiters work?

The design of the current limiter greatly dictates the inverter’s overall fault behavior. A well-established method to limit the inverter currents during faults is the current-reference saturation limiter, which curtails the reference signals feeding into the inner-current control loop .

Are current limiting and power adjustment strategies effective for grid-forming inverters?

In conclusion, this work has presented a comprehensive analysis of current limiting and power adjustment strategies for grid-forming inverters, particularly under fault conditions. The proposed control methodologies were tested using MATLAB Simulink to ensure their effectiveness in real-world scenarios.

Do limiting strategies protect inverters from overheating?

This thesis investigates current limiting strategies aimed at protecting inverters from overheating or undesired tripping. The primary focus is on understanding the implications of the current limiter on the overall system performance and developing methodologies to mitigate any adverse effects on the outer control loops.

How does current limiting affect inverter dynamic behavior?

The altered inverter dynamic behavior resulting from current limiting can affect the system. For instance, the change in inverter output terminal behaviors can translate to network-wide attributes, such as power system protection, transient stability, voltage support, and grid synchronization.

Can fault induced inverters lead to overcurrents in a grid forming inverter?

Fault induced will lead to overcurrents in grid forming inverters. Current limiting strategies are classified into voltage and current-based strategies. Transient current, current contribution and stability will depend on the strategy. Transient enhancing strategies are used to ensure the stability during faults.

What is a current limiter in a GFM inverter?

These devices regulate the flow of electrical current, ensuring it remains within safe operational limits. There are three main approaches to current limiting in GFM inverters: direct, indirect, and hybrid methods. These current limiters can be implemented at different stages, as shown in Fig. 2.

Guess what you want to know

-

Battery cabinet and current output control

Battery cabinet and current output control

-

Voltage-source inverter current control

Voltage-source inverter current control

-

Can a lead-acid battery be used with an inverter

Can a lead-acid battery be used with an inverter

-

48v base station battery with inverter

48v base station battery with inverter

-

Inverter Battery Requirements

Inverter Battery Requirements

-

Swiss inverter battery manufacturer

Swiss inverter battery manufacturer

-

Palestine BMS Battery Management Control System

Palestine BMS Battery Management Control System

-

Somalia PV water pump inverter control inverter

Somalia PV water pump inverter control inverter

-

40ah battery with inverter

40ah battery with inverter

-

Base station lithium battery energy storage 30kw inverter company

Base station lithium battery energy storage 30kw inverter company

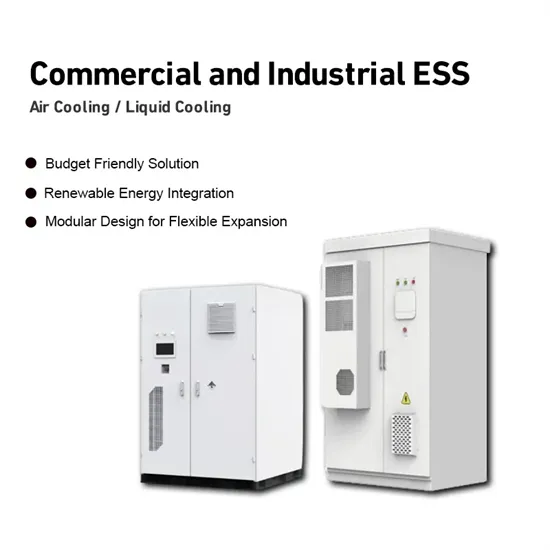

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.