South Sudan battery energy storage box custom-made factory

Redway 24V 200Ah LiFePO4 Battery in High Demand in Sudan How the Redway Battery is made. The Redway 24V 200Ah LiFePO4 Battery is one of the most in-demand

Get a quote

Affordable Lithium Batteries – Lithium Batteries South

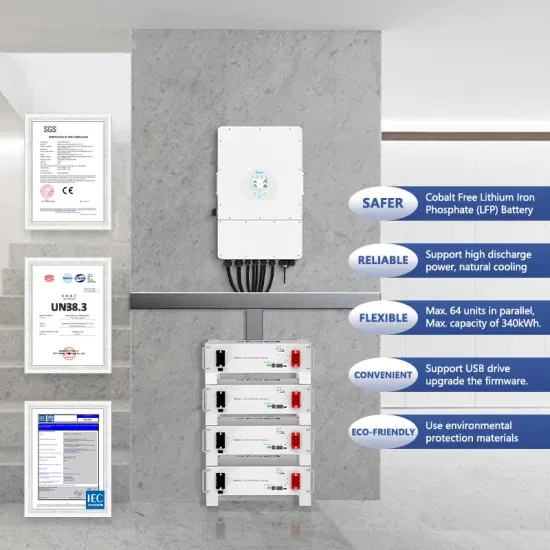

Lithium Batteries South Africa – High Voltage LiFePO₄ Battery Range Engineered and assembled locally, our High Voltage Lithium Iron Phosphate (LiFePO₄)

Get a quote

Mastering the Battery Pack Assembly Process: A

Conclusion The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy

Get a quote

Reliability Modeling Method for Lithium-ion Battery Packs

In order to accurately assess the reliability of lithium-ion batteries, it is necessary to build a reliability model considering the dependency among cells for the overall degradation of lithium

Get a quote

south sudan lithium battery energy storage battery

3-GWh lithium battery factory in South Carolina to make ESS for grid-scale applications Kontrolmatik Technologies, via its subsidiary Pomega Energy Storage Technologies, intends

Get a quote

South Sudan lithium battery assembly technology

By approaching specialized lithium-ion battery development as a cross-functional engineering challenge requiring rigorous validation, companies can successfully build custom packs

Get a quote

Africa''s Competitiveness in Global Battery Supply Chains

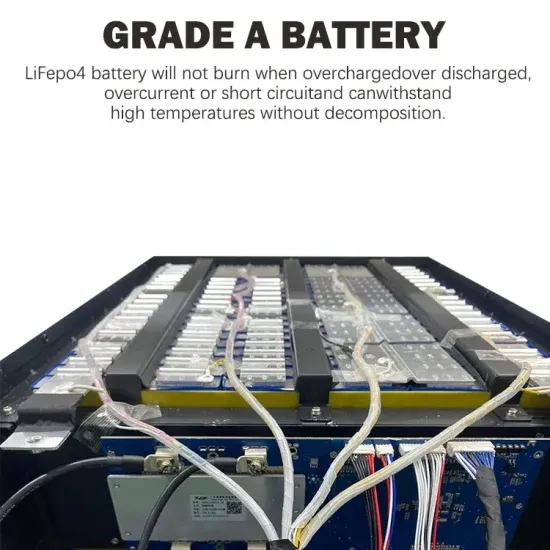

Context Battery packs can be assembled in African countries by importing cells and components (e.g., BMS, sensors, inverters) and tailoring battery modules to customer needs.

Get a quote

(PDF) A Comprehensive Review of Key Technologies

Therefore, exploring LIPB reliability technologies has become a vital research area. This paper aims to comprehensively summarize the

Get a quote

SOUTH SUDAN PORTABLE BATTERY PACK MARKET 2024

Lithium-ion (Li-ion) Battery Packs: Widely used in consumer electronics, electric vehicles, and energy storage systems, Li-ion battery packs offer high energy density, lightweight design, and

Get a quote

(PDF) A Comprehensive Review of Key Technologies for

Therefore, exploring LIPB reliability technologies has become a vital research area. This paper aims to comprehensively summarize the progress in LIPB reliability research.

Get a quote

South Sudan Lithium Energy Storage Power Direct Sales Store

Advanced Lithium-Ion Battery Storage Systems Our lithium-ion storage systems store excess energy generated during the day for use at night or during peak demand periods. Offering fast

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get a quote

A reliability design method for a lithium-ion battery pack

Because of the complexity of the battery pack, a reliability design method for a lithium-ion battery pack considering the thermal disequilibrium is proposed in this paper based

Get a quote

Battery Pack Manufacturing Process

From raw material selection to final assembly, each step plays a vital role in quality and reliability. In this post, you''ll learn the entire battery pack manufacturing process. We''ll

Get a quote

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

Conclusion Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this

Get a quote

SOUTH SUDAN LITHIUM ION CELL AND BATTERY PACK

How do I calculate the capacity of a lithium-ion battery pack? To calculate the capacity of a lithium-ion battery pack, follow these steps: Determine the Capacity of Individual Cells: Each

Get a quote

Detection method of lithium battery pack in South Sudan

This paper proposes a method for detecting the soft ISCr in the lithium-ion battery pack, where normal batteries and a battery with ISCr are connected in series, with the load currents and

Get a quote

Custom Lithium Ion Battery Packs vs Off-the-Shelf: What

Development timelines represent a critical design parameter when selecting between . custom lithium ion battery packs and off-the-shelf solutions. Standard battery packs

Get a quote

Leading Battery Pack Manufacturers in China: A 2025

Doctor of Science from Hubei University, Postdoctoral Fellow in Materials Science and Engineering from Central South University. Long-term

Get a quote

South Sudan Battery Project Environmental Assessment

Battery pack (51.2V 280AH) 19" rack backup battery: LiFePO4-based, ensures telecom and household energy backup with safety, high density,durability.

Get a quote

South sudan energy storage lithium battery price

A separate solar and storage project Scatec is building in South Africa, awarded to the firm through another procurement. Image: Scatec. Norway-based IPP Scatec has won preferred

Get a quote

Battery Pack Manufacturing Process

From raw material selection to final assembly, each step plays a vital role in quality and reliability. In this post, you''ll learn the entire battery

Get a quote

Reliability Modeling and Analysis of Lithium-Ion Battery Packs in

Reliability Modeling and Analysis of Lithium-Ion Battery Packs in Renewable Energy Systems Published in: 2024 8th International Conference on System Reliability and Safety (ICSRS)

Get a quote

Africa''s Competitiveness in Global Battery Supply Chains

African countries, particularly Tanzania and Morocco, could competitively produce and export LFP batteries to Europe by 2030 at USD 68-72/kWh.

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Get a quote

A review of state-of-health estimation for lithium-ion battery packs

With the rapid advancement of lithium-ion battery technology, the estimation of the state of health (SOH) of lithium-ion battery packs plays a crucial role in enhancing the safety

Get a quote

South Sudan lithium battery project planning

Compressed air and gas for electric car battery production Each electrical or hybrid-driven vehicle requires large amounts of lithium-ion cells. These li-ion battery cells are assembled into a

Get a quote

6 FAQs about [Reliability of lithium battery packs assembled in South Sudan]

Can we predict the SoH of lithium-ion battery packs?

Although our methods for predicting the SOH of Li-ion battery packs have developed relatively well, there are still the following shortcomings: Today's lithium-ion battery market is dominated by lithium cobaltate, lithium ternary and lithium iron phosphate batteries.

What indicators are used to assess the SoH of lithium-ion batteries?

Two indicators are typically used to assess the SOH of lithium-ion batteries and battery packs: capacity and internal resistance: where Q present and Q new represent the maximum capacity of the battery pack under the current cycle and the maximum capacity of the new battery pack, respectively.

Why do lithium ion batteries have inconsistency?

Lithium-ion battery pack inconsistency. During both charging and discharging processes, parallel-connected lithium-ion batteries maintain equivalent terminal voltages. However, due to variations in the direct current internal resistance among individual cells, the current distribution through each battery differs .

What is Soh in a lithium ion battery pack?

Lithium-ion battery pack SOH estimation The definition of SOH for lithium-ion batteries and battery packs is essentially the same, it represents the ratio of the current performance of the battery pack to its performance at the beginning .

What is a lithium ion battery pack?

Li-ion battery packs are composed of multiple lithium-ion battery monomer by series, parallel or series-parallel combination to obtain higher voltage and enhanced capacity to fulfill the requirements of the equipment.

Do lithium ion batteries have a degradation feature?

They proposed a novel degradation feature for modeling Li-ion battery pack health. Their investigation examined the charging cutoff voltage inconsistency of each lithium-ion cell in the context of actual operation, with findings indicating that this inconsistency is prevalent among individual units and follows a normal distribution.

Guess what you want to know

-

Are lithium battery packs assembled in Eastern Europe

Are lithium battery packs assembled in Eastern Europe

-

South Sudan outdoor power lithium battery price

South Sudan outdoor power lithium battery price

-

South Sudan lithium battery bms

South Sudan lithium battery bms

-

Sudan lithium battery bms characteristics company

Sudan lithium battery bms characteristics company

-

Battery Packs and Lithium Batteries

Battery Packs and Lithium Batteries

-

Secondary lithium battery packs and lithium batteries

Secondary lithium battery packs and lithium batteries

-

Global procurement of lithium battery packs

Global procurement of lithium battery packs

-

South America graphene lithium battery pack

South America graphene lithium battery pack

-

Solomon Islands produces solar lithium battery packs

Solomon Islands produces solar lithium battery packs

-

Enterprises capable of producing lithium battery packs

Enterprises capable of producing lithium battery packs

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.