What Are Solar Panels Made Of and How Are They Made?

Solar panels are usually made from a few key components: silicon, metal, and glass. Standard panels are either made from monocrystalline or polycrystalline silicon. Start

Get a quote

Solar Panel Connector Cable 10AWG 20Ft SAE Adapter

Solar Panel Connector Cable - 10AWG 20Ft SAE Adapter. Upgrade your solar energy system with our Solar Panel Connector Cable, designed for reliability and efficiency. With its heavy

Get a quote

Unbound Solar® – Solar Products & DIY Advice by

Unbound Solar®, formerly Wholesale Solar, sells the best solar products & parts for off-grid, grid-tie, & custom solar solutions.

Get a quote

The Manufacturing Process of Solar Panels: From Raw Materials

Discover the fascinating journey of solar panel creation, as we unveil the intricate steps in the manufacturing process from raw materials to energy.

Get a quote

What Materials Can be Recycled from Solar Panels?

With the increasing popularity of photovoltaic power generation, the issue of end-of-life solar panel disposal has come to the forefront. Fortunately,

Get a quote

Solar Panel Manufacturing Process: Step-by-Step Guide

The key components in solar PV manufacturing include silicon wafers, solar cells, PV modules, and solar panels. Silicon is the primary material used, which is processed into

Get a quote

Different Types Of Solar Panels In India: Cost, Efficiency & Power

Explore 10 different types of solar panels in India, ranging from first-generation monocrystalline panels to the advanced types of solar panels for houses, including bifacial

Get a quote

Solar Panel Manufacturing : Process, Production

Solar panels are a vital component of renewable energy systems, converting sunlight into electricity. Understanding the manufacturing

Get a quote

Solar Panel Manufacturing : Process, Production Stages

Dive deep into the fascinating world of solar panel manufacturing processes, including different solar cell types. Learn how these panels are made step-by-step and unlock

Get a quote

What Materials Can be Recycled from Solar Panels?

With the increasing popularity of photovoltaic power generation, the issue of end-of-life solar panel disposal has come to the forefront. Fortunately, these panels contain several

Get a quote

Solar Panel Manufacturing

Custom-designed solutions tailored to the specific needs of solar panel manufacturers. Proven track record in helping manufacturers achieve higher efficiency, lower costs, and regulatory

Get a quote

Steel Products for Solar Installations

Steel products commonly used in solar installations include solar panel mounts, steel tubing, flat-rolled steel products, and corrosion-resistant steel. Solar panel mounts and

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get a quote

Nigeria''s Ministry of Finance has issued a new VAT

Petroleum products – The Schedule to the Order exempts petroleum products from VAT, including aviation and motor spirit, kerosene, natural gas, other liquefied petroleum gases and

Get a quote

The Lifecycle of Solar Panels: From Raw Materials to Recycling

Discover the hidden journey behind solar energy as we uncover the intricate lifecycle of solar panels. From the extraction of raw materials to their end-of-life management,

Get a quote

Renewable Energy Waste Streams: Preparing for the Future

A renewable energy system can only be as green and sustainable as the manner in which wastes are minimized, repurposed, and/or disposed. In this summary, focuses on solar panels,

Get a quote

Where can I get solar panels processed? | NenPower

Exploring the landscape of local manufacturers is a vital step in pinpointing where to get solar panels processed effectively. Many regions have dedicated companies focused on

Get a quote

The Lifecycle of Solar Panels: From Raw Materials to

Discover the hidden journey behind solar energy as we uncover the intricate lifecycle of solar panels. From the extraction of raw materials to

Get a quote

6 FAQs about [Solar panel processed products]

How are solar panels made?

Silicon is one of the most important materials used in solar panels, making up the semiconductors that create electricity from solar energy. However, the materials used to manufacture the cells for solar panels are only one part of the solar panel itself. The manufacturing process combines six components to create a functioning solar panel.

What is the manufacturing process of solar panels?

Understanding this process is crucial for advancing sustainable energy solutions. The manufacturing process of solar panels primarily involves silicon cell production, panel assembly, and quality assurance.

Which raw material is used to make solar panels?

The primary raw material in solar panel production is silicon, which is derived from quartzite sand. Silicon is abundant on Earth and plays a crucial role due to its semiconductor properties. The quartzite undergoes purification to extract silicon, which is essential for creating solar cells. 2. Silicon Ingot Formation

What are the main aspects of solar panel manufacturing?

This comprehensive article covers the main aspects of solar panel manufacturing, including types, raw materials, production stages, environmental impact, recycling, and future trends. Solar panels come in different types, such as monocrystalline, polycrystalline, and thin-film solar panels.

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

How are monocrystalline solar panels made?

Monocrystalline solar panels are produced from one large silicon block in silicon wafer formats. The manufacturing process involves cutting individual wafers of silicon that can be affixed to a solar panel. Monocrystalline silicon cells are more efficient than polycrystalline or amorphous solar cells.

Guess what you want to know

-

Photovoltaic company s main solar panel products

Photovoltaic company s main solar panel products

-

Differences between solar panel products of various companies

Differences between solar panel products of various companies

-

Solar photovoltaic panel edge pressing

Solar photovoltaic panel edge pressing

-

Algeria solar panel assembly

Algeria solar panel assembly

-

How many watts are needed for a civilian solar panel

How many watts are needed for a civilian solar panel

-

What size inverter should I use for a 50w solar panel

What size inverter should I use for a 50w solar panel

-

Austrian energy storage solar panel manufacturer

Austrian energy storage solar panel manufacturer

-

Photovoltaic solar panel prices in Andorra

Photovoltaic solar panel prices in Andorra

-

Solar panel light thickness

Solar panel light thickness

-

Which solar panel and photovoltaic module manufacturer is best in Guinea

Which solar panel and photovoltaic module manufacturer is best in Guinea

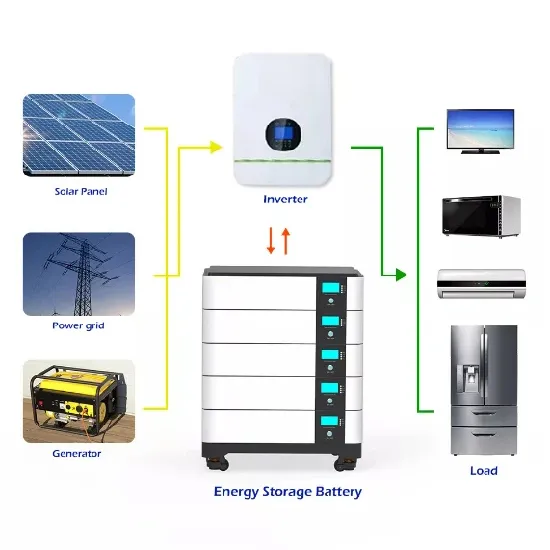

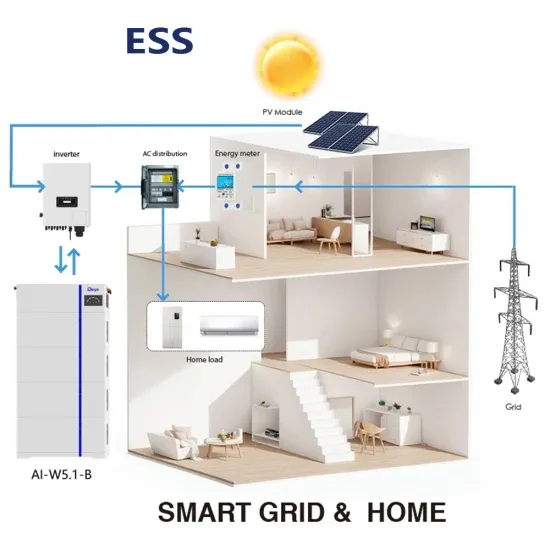

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

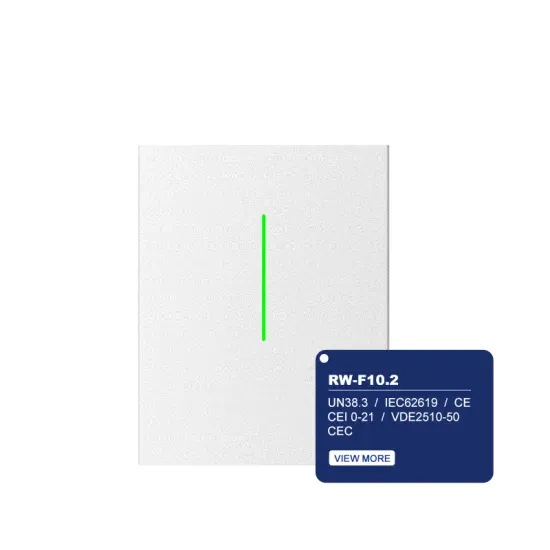

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.