Photovoltaic edge voltage firmly support modules

In a word, the photovoltaic edge pressing parts provide stability and reliability for the photovoltaic system by firmly supporting and optimizing the power generation efficiency.

Get a quote

Photovoltaic Panel Bracket Aluminum Alloy Film Edge

The company occupies an area of 24 acres and has a full set of production lines for anti-seismic support and hanger accessories, photovoltaic solar brackets,

Get a quote

Solar photovoltaic module side pressure block

solar panels weigh around 40 pounds (18 kg). These weights suggest that glass-on-glass PV modu In this project, a solar panel array mounted at the ground plane is subject to wind

Get a quote

The importance of photovoltaic edge clamps-Niunan Fastener

The main function of the edge pressure block is to evenly distribute the pressure exerted on the edges of the solar panels. This helps to prevent any potential damage or

Get a quote

Solar Panel Edge Seal: Liquid Applied vs. Tape

The process of edge sealing the panels can make or break the quality of the panel when it is exposed to weather elements. This article explains the benefits of using dispensing equipment

Get a quote

How to press the edge of solar panels | NenPower

Careful attention to pressing the edges of solar panels plays a pivotal role in their performance and longevity. Ensuring proper alignment,

Get a quote

Solar Panel Edge Seal: Liquid Applied vs. Tape

The process of edge sealing the panels can make or break the quality of the panel when it is exposed to weather elements. This article explains the

Get a quote

Photovoltaic pressure plate Solar cell panel edge pressing Photovoltaic

Photovoltaic Pressure Plate Solar Cell Panel Edge Pressing Photovoltaic Pressure Plate Bracket Accessories, Find Complete Details about Photovoltaic Pressure Plate

Get a quote

Photovoltaic Panel Bracket Aluminum Alloy Film Edge Pressing

The company occupies an area of 24 acres and has a full set of production lines for anti-seismic support and hanger accessories, photovoltaic solar brackets, and more than 30 assembly lines

Get a quote

Solaredge Unveils Next Generation All One Home

SolarEdge developed an intelligent inverter solution that changed the way power is harvested and managed in photovoltaic (PV) systems. The

Get a quote

Photovoltaic Panel Bending and Pressing Block Installation: The

Whether you''re dealing with traditional silicon panels or cutting-edge perovskite modules, mastering photovoltaic panel bending and pressing block installation techniques separates the

Get a quote

How to press the solar panel | NenPower

Yes, improper pressing techniques can indeed damage solar panels. The primary risk comes from applying uneven pressure, which can lead to micro-cracking or other

Get a quote

Photovoltaic Fasteners and Accessories | Future Energy Steel

Photovoltaic Fasteners and Accessories Photovoltaic fasteners and accessories are essential components for securing and optimizing solar panel installations. Designed for durability and

Get a quote

CN202758902U

The edge pressing block device has characteristics of a simple structure, easy installation, and firm installation and prevents damage to the surface of the solar energy photovoltaic...

Get a quote

Lamination Technology – PV Panels

The effect of cooling press on the encapsulation properties of crystalline photovoltaic modules: residual stress and adhesion. Progress in Photovoltaics Research and Applications, DOI:

Get a quote

U-shaped edge pressure block for photovoltaic panels

Under the direct exposure of sunlight, photovoltaic (PV) panels can only convert a limited fraction of incident solar energy into electricity, with the rest wasted as heat. 1, 2, 3

Get a quote

Boost Efficiency with Durable photovoltaic panel pressing block

Enhance your energy solutions with durable and efficient photovoltaic panel pressing block . Designed for easy installation, they offer stability and flexibility for various setups.

Get a quote

Solar Powering People''s Lives Around the USA

Backed by the world''s biggest insurers, SolarEdge Commercial uses exclusive SafeDC technology to meet and exceed current safety requirements, ensuring

Get a quote

A review of solar photovoltaic technologies: developments,

A historical perspective is provided, tracing PV technology from the discovery of the photovoltaic effect in 1839 to its latest innovations, such as high-efficiency cells, bifacial

Get a quote

How to press the edge of solar panels | NenPower

Careful attention to pressing the edges of solar panels plays a pivotal role in their performance and longevity. Ensuring proper alignment, utilizing suitable tools, and enforcing

Get a quote

Photovoltaic panel gap sealing tape

Below is a step-by-step procedure of how to seal between solar panels using a silicone sealant: Clean the surface to get rid of tape or any other material before starting the sealing process.

Get a quote

New Cable Management Clips for Efficient Solar

A. JET PRESS provides a wide variety of solar panel clips, including PV module clips, top rail clips, and bespoke clips. Our products are

Get a quote

Innovations in improving photovoltaic efficiency: A review of

This review paper presents a comprehensive analysis of state-of-the-art innovations in PV efficiency enhancement techniques, including cooling methods, mobile PV systems,

Get a quote

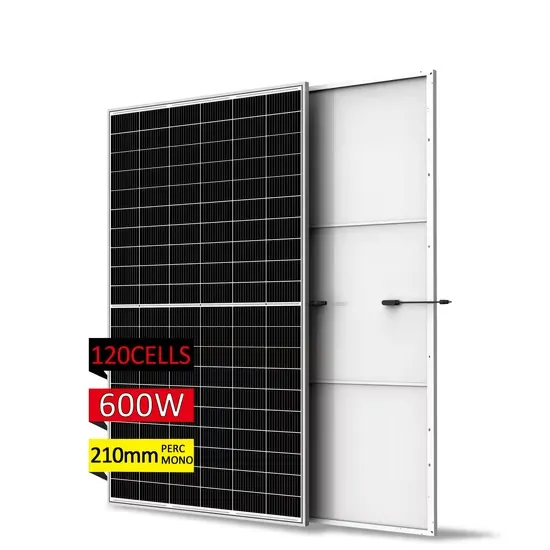

Photovoltaic Module: Definition, Importance, Uses and Types

Photovoltaic modules, or solar modules, are devices that gather energy from the sun and convert it into electrical power through the use of semiconductor-based cells. A

Get a quote

4 FAQs about [Solar photovoltaic panel edge pressing]

Do solar panels need to be edge sealed?

Solar panel manufacturing is complex and challenging. One challenge involves the need to seal the panel against the weather elements to which it will be exposed. The process of edge sealing the panels can make or break the quality of the panel when it is exposed to weather elements.

What is solar panel edge tape (PSET)?

The liquid edge seal is applied in a continuous bead all the way around the perimeter of the solar panel. For solar panel manufacturing, long-term success hinges on developing and perfecting the right process. Shifting from edge tape to pumpable solar panel edge tape (PSET) can improve your manufacturing efficiency and product quality.

Why do solar panels need a pset process?

A reliable trend for solar panel manufacturing, switching to PSET processes has benefitted companies in many ways. The PSET liquid edge seal is applied in a continuous bead all the way around the perimeter of the solar panel.

Why do solar panels need to be sealed?

Simply put, moisture is the enemy of solar panels. Moisture ingress into the panel causes poor performance and premature failure, so properly sealing the panel against moisture is of utmost importance. Because of this importance, much time and effort are spent on this step of the manufacturing process.

Guess what you want to know

-

North American solar photovoltaic panel advantages

North American solar photovoltaic panel advantages

-

7w solar panel photovoltaic panel

7w solar panel photovoltaic panel

-

Nicaragua solar panel photovoltaic module manufacturer

Nicaragua solar panel photovoltaic module manufacturer

-

Vietnam photovoltaic panel single solar panel

Vietnam photovoltaic panel single solar panel

-

Thailand Solar Photovoltaic Panel Project

Thailand Solar Photovoltaic Panel Project

-

How many solar panels are needed for a photovoltaic panel

How many solar panels are needed for a photovoltaic panel

-

Gambia Solar Panel Photovoltaic Project

Gambia Solar Panel Photovoltaic Project

-

Solar Panel Policy Discussion Photovoltaic

Solar Panel Policy Discussion Photovoltaic

-

Photovoltaic panel single wave solar panel removal equipment

Photovoltaic panel single wave solar panel removal equipment

-

French home solar photovoltaic panel installation

French home solar photovoltaic panel installation

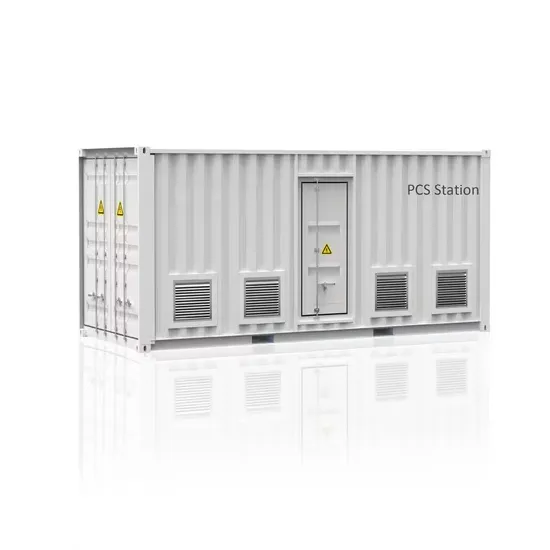

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.