NiCD VENTED TYPE FIBRE PLATE

NiCD VENTED TYPE FIBRE PLATE Nickel cadmium batteries offer the user the most reliable battery available for industrial applications today. They are extremely robust – sustaining

Get a quote

Batteries Flashcards | Quizlet

Study with Quizlet and memorize flashcards containing terms like What may result if water is added to a nickel cadmium battery when it is not fully charged?, The specific gravity of a lead

Get a quote

Safety Data Sheet for Nickel Cadmium Batteries

Do not store/operate the Nickel Cadmium batteries in the same room where the lead acid batteries are stored / operated. Keep away from water. Do not use the tools used for lead acid

Get a quote

South America Battery Market Forecast | Industry

South and Central America Battery Market Size & Share Analysis - Growth Trends & Forecasts (2025 - 2030) The South And Central America

Get a quote

Specification for Nickel Cadmium Battery

Nickel cadmium batteries are part of this supply and are required for the stable supply of electricity. The purpose of this specification is to detail the technical requirements for vented

Get a quote

Ni-Cd Block battery range

Saft operates the only plant in the world that produces nickel-cadmium batteries incorporating metals that have been reclaimed on site from spent batteries, reducing their eco-footprint. The

Get a quote

Battery Shipping Logistics: A Guide for Shipping

This overview examines key logistical factors for transporting major battery technologies, including lead-acid, lithium-ion, nickel-cadmium,

Get a quote

Ni-Cd | Saft

Saft operates the only plant in the world that produces nickel-cadmium batteries incorporating metals that have been reclaimed on site from spent batteries, reducing their eco-footprint.

Get a quote

Battery Shipping Logistics: A Guide for Shipping Different Battery

This overview examines key logistical factors for transporting major battery technologies, including lead-acid, lithium-ion, nickel-cadmium, nickel-metal hydride, alkaline,

Get a quote

Standard Operating Procedure for Batteries 9/25/13

Mercury Sodium Chloride Nickel Cadmium Batteries are managed as Universal Wastes. They are collected in properly labeled containers in designated areas around campus. The label must

Get a quote

Technical Data of our Nickel Cadmum Battery | Nicad Power Pte Ltd

NICA Nickel Cadmium Battery is the most reliable source for standby power backup today. The Nickel Cadmium battery is designed and manufactured for a wide variety of harsh

Get a quote

SAFETY DATA SHEET

The Nickel-Cadmium cell or battery described by this Battery Information Sheet is a manufactured "article" and does not expose the user to hazardous chemicals when used in accordance with

Get a quote

EnviroGuard

Battery Recycling Containers With different levels of pails, our battery recycling program can accommodate up to 50lbs of dry cell batteries can be loaded into the UN approved 3.5-gallon

Get a quote

Saft America: half a century in the United States

Saft has been operating in America for half of its 100-year history. In that time, it has gone from one site to five key locations across the US and now produces

Get a quote

Weight of Nickel

The main reason for the relatively high weight of Ni - Cd batteries is the use of cadmium in the negative electrode. Cadmium is a dense metal, and its presence in the battery contributes

Get a quote

Battery Shipping: Classification, Best Practices, and more | Maersk

Shipping batteries? Learn about their classification, preparation for transport, various shipping modes involved, and FAQs to ensure a smooth transit.

Get a quote

Battery Recycling

Wide range of batteries recycled, including: Alkaline; lead acid; lithium / lithium ion; mercury; nickel-cadmium; nickel metal hydride, silver; zinc carbon and more. We make recycling

Get a quote

hblbatteries

The wide range of Nickel Cadmium Fibre Plate batteries are available in tough, fusion-welded polypropylene cell containers and lids. When placed on multi-step battery racks, the electrolyte

Get a quote

Batscan

The Nickel-Cadmium (NiCd) battery, which is an alkali accumulator, was invented by Waldemar Jungner (1869-1924). It was patented in September 1899 and has since been produced by

Get a quote

Typical materials composition (by percentage weight)

The composition of the various constituents of Ni-Cd batteries by percentage weight used for automotive and portable electronic applications is given in

Get a quote

Battery Packaging Requirements and Shipping Restrictions

Regulations for packaging and shipping batteries can be complicated. Learn the regulations for some of the most common types of batteries.

Get a quote

SDS Nickel Cadmium PP Containers | PDF | Battery

This document provides a safety data sheet for nickel cadmium batteries. It identifies the product and supplier, lists hazards such as corrosive electrolyte,

Get a quote

Battery Shipping: Classification, Best Practices, and

Shipping batteries? Learn about their classification, preparation for transport, various shipping modes involved, and FAQs to ensure a smooth

Get a quote

Typical materials composition (by percentage weight) of the Nickel

The composition of the various constituents of Ni-Cd batteries by percentage weight used for automotive and portable electronic applications is given in Table 5.

Get a quote

Batteries, wet, filled with alkali, electric storage

Substance information for UN 2795 - Batteries, wet, filled with alkali, electric storage based on the Hazardous Materials Table (Title 49 CFR 172.101) to assist in preparing a risk assessment for

Get a quote

6 FAQs about [Weight of nickel-cadmium batteries in containers in South America]

What is a nickel cadmium battery?

Nickel cadmium batteries are part of this supply and are required for the stable supply of electricity. The purpose of this specification is to detail the technical requirements for vented prismatic nickel cadmium battery cells in City Power’s substations.

What are wet cell nickel cadmium batteries used for?

Wet cell nickel cadmium batteries are often used in aviation for stand-by power and emergency lights, as well as in other situations where large capacities and high discharge rates are needed. They have certain packing and shipping requirements.

How do you package a wet cell nickel cadmium battery?

They have certain packing and shipping requirements. Wet cell nickel cadmium batteries should be packaged in a way that ensures the terminals will not touch each other by putting non-conductive caps on them, bagging them individually, placing non-conductive tape on them, or using the original packaging.

Are nickel cadmium batteries a universal waste?

Nickel-cadmium batteries are also generally considered universal waste. Disposing of these batteries in landfills can cause soil contamination and water pollution. This is why they require special packaging and disposal. Here are some of the packaging and shipping requirements for some of the most common batteries classified as universal waste.

What is DC supply & cadmium battery?

DC supply forms an integral part of City Power network; it’s used for substation backup supply for Protection Power System. Nickel cadmium batteries are part of this supply and are required for the stable supply of electricity.

What is a nickel-metal hydride battery?

Nickel-metal hydride batteries fall in the UN class 9 (miscellaneous dangerous goods) and hold the HS code 8507.50. These are a replacement for NiCd rechargeable batteries and are used where high power is needed like cameras. The top logistical considerations for shipping these types include:

Guess what you want to know

-

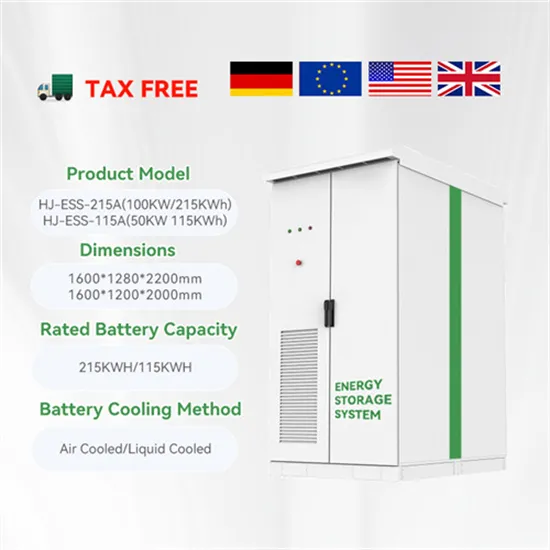

Uzbekistan s energy storage batteries are shipped in containers for sale

Uzbekistan s energy storage batteries are shipped in containers for sale

-

Photovoltaic solar panels on roofs in South America

Photovoltaic solar panels on roofs in South America

-

Solar panel projects under construction in northwest South America

Solar panel projects under construction in northwest South America

-

Solar power generation system installed in South America

Solar power generation system installed in South America

-

Installing solar energy on roof tiles in South America

Installing solar energy on roof tiles in South America

-

South America communication base station inverter grid connection

South America communication base station inverter grid connection

-

South America lithium battery bms wholesale

South America lithium battery bms wholesale

-

Liquid Cooling Energy Storage Container Prices in South America

Liquid Cooling Energy Storage Container Prices in South America

-

Characteristics of South Sudan energy storage batteries

Characteristics of South Sudan energy storage batteries

-

Long-term supply of three-phase sine wave inverters in South America

Long-term supply of three-phase sine wave inverters in South America

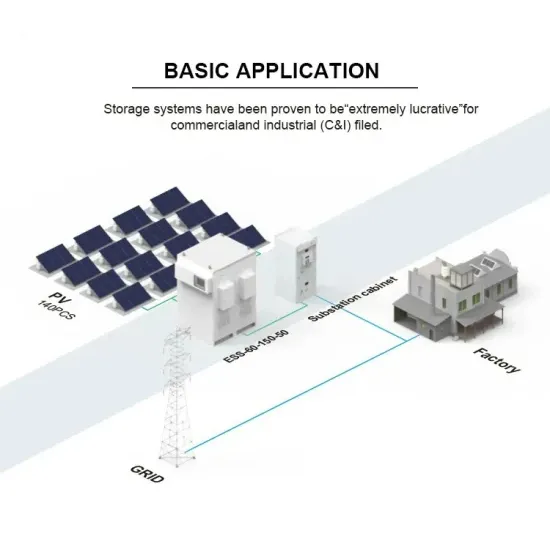

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.