Techno-economic performance comparison of crystalline and thin film PV

Photovoltaic panel technologies have evolved considerably over a limited period. The most popular PV panel technologies can be divided into two main groups, the first being

Get a quote

International Journal of Research Publication and Reviews

Through an extensive literature review, the study concludes that despite the introduction of these new technologies, silicon-based photovoltaic cells still hold the largest market share. Ongoing

Get a quote

Solar Power:

Solar Power: Solar power is an indefinitely renewable source of energy as the sun has been radiating an estimated 5000 trillion kWh of energy for billions of years and will continue to do

Get a quote

A Guide On Silicon Crystalline: Its Types, Working, Uses, and Prices

Crystalline silicon is the leading semiconducting material extensively used in photovoltaic technology for manufacturing solar cells. The silicon crystalline photovoltaic cells

Get a quote

PV cells and modules – State of the art, limits and trends

Electrical engineering; Energy; Environmental science; Photovoltaics; PV technology; Crystalline silicon PV modules; Thin film PV modules; PV module service life; PV module price; Levelized

Get a quote

How much does crystalline silicon solar energy cost per square

The type of installation has a profound effect on the overall expenditures related to crystalline silicon solar energy systems. Residential installations, typically ranging from small

Get a quote

Crystalline Silicon Solar Cell

2.1 Crystalline silicon solar cells (first generation) At the heart of PV systems, a solar cell is a key component for bringing down area- or scale-related costs and increasing the overall

Get a quote

Introduction of Solar Crystalline Silicon and Thin Film Battery

Brice Solar will introduce the technical characteristics and commercial value of the two major crystalline silicon and thin-film cell technologies from the dimensions of material

Get a quote

Status and perspectives of crystalline silicon photovoltaics in

Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost.

Get a quote

Crystalline Silicon Photovoltaics Research

What is a Crystalline Silicon Solar Module? A solar module—what you have probably heard of as a solar panel—is made up of several small solar cells wired together inside a protective casing.

Get a quote

A Guide On Silicon Crystalline: Its Types, Working,

Crystalline silicon is the leading semiconducting material extensively used in photovoltaic technology for manufacturing solar cells. The

Get a quote

Solar PV cell materials and technologies: Analyzing the recent

The solar PV cells based on crystalline-silicon, both monocrystalline (m-crystalline) and polycrystalline (p-crystalline) come under the first generation solar PV cells.

Get a quote

Types of Solar Panels: Monocrystalline vs

Introduction: Solar panels are a popular choice for renewable energy generation. It is important to understand the different types of solar

Get a quote

Understanding Crystalline Silicon PV Technology

Learn everything you need to know about Crystalline Silicon PV technology, from its basic principles to its applications in solar panels.

Get a quote

PV cells and modules

Electrical engineering Energy Environmental science Photovoltaics PV technology Crystalline silicon PV modules Thin film PV modules PV module service life PV module price

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

Solar Manufacturing Cost Analysis NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and

Get a quote

Heterojunction (HJT) Solar Panels: How They Work

Indium Tin Oxide (ITO) Crystalline silicon is regularly used to create standard homojunction solar cells, seen in conventional panels. There

Get a quote

Crystalline-Silicon Solar Cells for the 21st Century

The worldwide market share for crystalline-silicon solar cells has increased steadily in the last 10 years. In 1998, about 87% of the photovoltaic modules shipped worldwide are based on

Get a quote

Crystalline Silicon Photovoltaic Module Manufacturing Costs

This report updates c-Si PV supply-chain costs and projections generated from detailed bottom-up cost modeling at the National Renewable Energy Laboratory (NREL), which began in 2010

Get a quote

A Comprehensive Guide to Crystalline Silicon (c-Si) PV Panels

By understanding their types, applications, advantages, production process, and purchasing factors, you can confidently select the right c-Si PV panels for your solar project and contribute

Get a quote

An introduction to solar Polycrystalline Modules

Polycrystalline silicon (polysilicon) is the material used to manufacture crystalline silicon PV modules and consists of small silicon

Get a quote

Crystalline Silicon Solar Cell

These types of solar cells are further divided into two categories: (1) polycrystalline solar cells and (2) single crystal solar cells. The performance and efficiency of both these solar cells is almost

Get a quote

Monocrystalline Solar Panel In India: Types & Solar

The monocrystalline solar panel price is determined by its silicon structure, electrical protection, and wiring. While producing monocrystalline

Get a quote

PV cells and modules – State of the art, limits and trends

At present, the wafer-based crystalline silicon technologies have best met the criteria due to their high efficiency, low cost and long service time; and due to the abundance of materials, they

Get a quote

6 FAQs about [Introduction and price of crystalline silicon photovoltaic panels]

What are crystalline silicon photovoltaic modules?

The Crystalline silicon photovoltaic modules are made by using the silicon crystalline (c-Si) solar cells, which are developed in the microelectronics technology industry. The PV solar panels are composed of these solar cells as part of a photovoltaic system to produce solar energy from sunlight.

What is crystalline silicon PV technology?

Photovoltaic technology, also known as solar power, harnesses the sun’s energy to generate electricity through the use of photovoltaic cells. Understanding photovoltaic technology, and in particular, crystalline silicon PV technology is crucial for those seeking to adopt renewable energy solutions.

What is the efficiency of crystalline silicon solar cells?

Coming to the efficiency of crystalline silicon PV cells, it varies with different types. Mono-crystalline silicon PV cells have an energy conversion efficiency of more than 25%, and that of polycrystalline cells is around 20%. Some major advantages of crystalline silicon solar cells are:

What are crystalline silicon solar cells?

Crystalline silicon solar cells are today’s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This Review discusses the recent evolution of this technology, the present status of research and industrial development, and the near-future perspectives.

What is the difference between silicon crystalline and traditional solar cells?

The traditional solar cells are manufactured with silicon, and they are the most efficient solar cells available at the present time. Silicon Crystalline, on the other hand, is basically the crystalline form of silicon.

Are silicon crystalline solar cells a good investment?

Since the early 1950s, Silicon crystalline solar cells have overpowered the global photovoltaic market. Silicon is an abundant and non-toxic element available in the earth’s crust. Over the years in practice, crystalline silicon PV modules have exhibited their long-standing performance.

Guess what you want to know

-

Price of crystalline silicon photovoltaic modules

Price of crystalline silicon photovoltaic modules

-

Price difference of monocrystalline silicon photovoltaic panels of the same specifications

Price difference of monocrystalline silicon photovoltaic panels of the same specifications

-

Price of solar photovoltaic panels

Price of solar photovoltaic panels

-

Crystalline silicon photovoltaic curtain wall design

Crystalline silicon photovoltaic curtain wall design

-

Iceland non-standard photovoltaic curtain wall solar panel components crystalline silicon

Iceland non-standard photovoltaic curtain wall solar panel components crystalline silicon

-

Selling price of new photovoltaic panels in the Netherlands

Selling price of new photovoltaic panels in the Netherlands

-

How much is the price of BESS photovoltaic panels in Tuvalu

How much is the price of BESS photovoltaic panels in Tuvalu

-

How much is the price of Swiss photovoltaic panels BESS

How much is the price of Swiss photovoltaic panels BESS

-

Price High-efficiency photovoltaic panels

Price High-efficiency photovoltaic panels

-

Contract price of photovoltaic panels in Somalia

Contract price of photovoltaic panels in Somalia

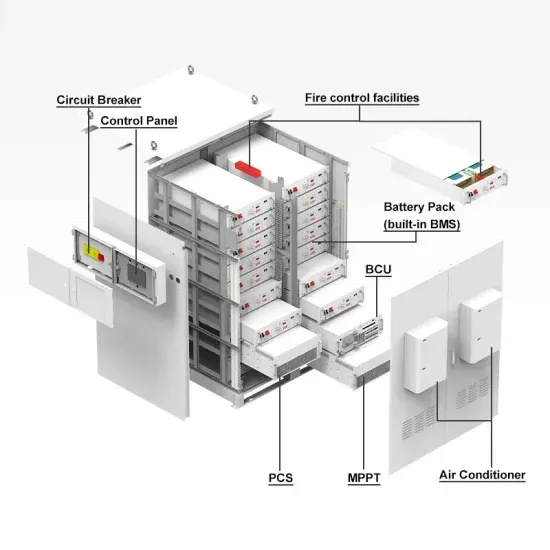

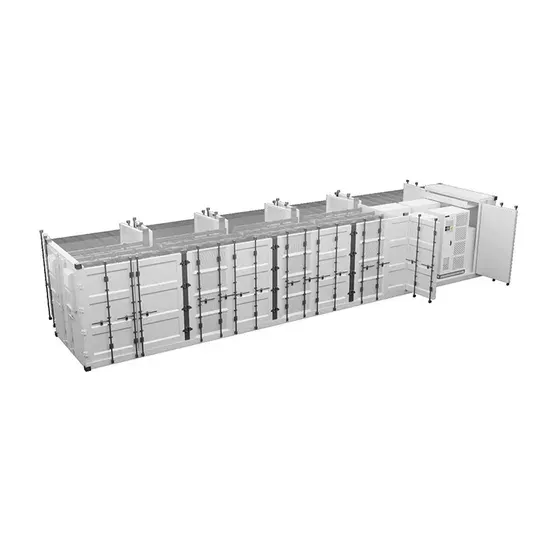

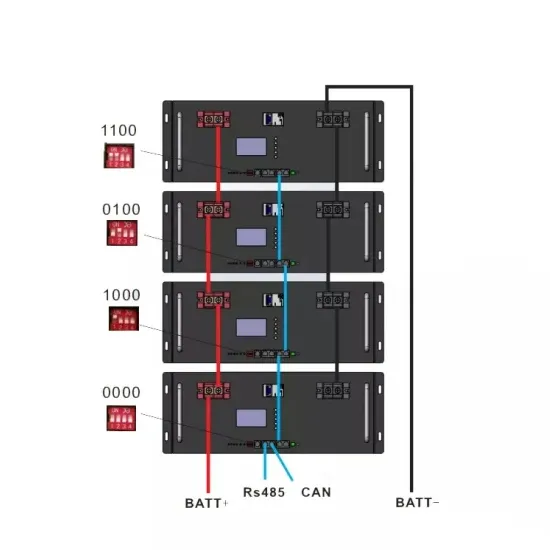

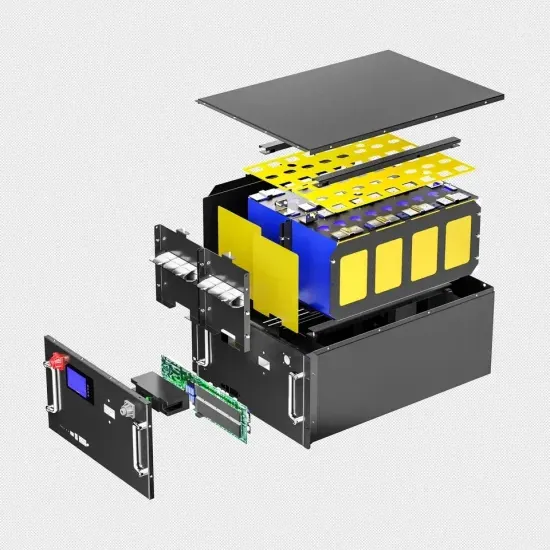

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.