Understanding Temperature Effects on Crystalline PV Modules

As additional unused power in PV modules is reduced in high temperature, so is the advantage of MPPT charge controllers. Therefore, even at normal operating temperatures, the additional

Get a quote

The Effect of Heat and Temperature on Photovoltaic Modules

PV modules and cells are meant to convert the light from the sun into electricity. This implies hours and hours of exposure to the sun’s heat for the PV modulessola. The way

Get a quote

The Effect of Heat and Temperature on Photovoltaic

An Introduction to Heat and Photovoltaics PV modules and cells are meant to convert the light from the sun into electricity. This implies hours and

Get a quote

RE+: Ten cutting-edge technologies from North America''s largest

3 days ago· New solar panels, battery energy storage systems, factory announcements and more are set to be unveiled at RE+ Las Vegas, Nevada, Sep 8-11.

Get a quote

The environmental factors affecting solar photovoltaic output

The Nominal Operating Cell Temperature (NOCT) for 21,000 commercially-available solar PV modules, aggregated by cell technology. Data from the CEC database [17].

Get a quote

Photovoltaic Power System Overcurrent Protection:

With PV modules, both the voltage and current outputs, while rated at a set of standard test conditions, vary significantly with solar irradiance and

Get a quote

Solar Panel Datasheet Specifications Explained

Solar modules must also meet certain mechanical specifications to withstand wind, rain, and other weather conditions. An example of a solar panel datasheet composed of wafer-type PV cells is

Get a quote

Thermal performance of Si and GaAs based solar cells and modules

This review summarizes the recent progress obtained in the field of the temperature performance of crystalline and amorphous silicon solar cells and modules. It gives a general

Get a quote

Global perspectives on advancing photovoltaic system

Consequently, effective solutions are critical for achieving high solar PV performance. This work aims to consolidate and provide a unique global review of pioneering

Get a quote

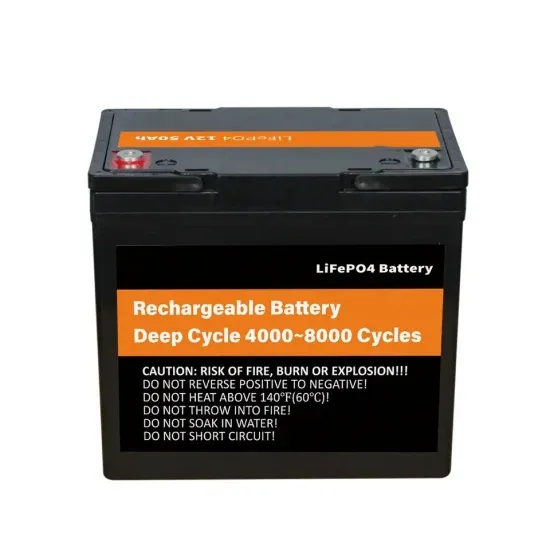

What impact does temperature have on the longevity

Accelerated Degradation: High temperatures can cause solar batteries to degrade faster, reducing their lifespan. This is particularly true for

Get a quote

Temperature Dependent Photovoltaic (PV) Efficiency and Its

The operating temperature plays a key role in the photovoltaic conversion process. Both the electrical efficiency and the power output of a photovoltaic (PV) module depend

Get a quote

PV Module Performance Differences in High Temperatures

Irradiance and module temperature are the two key factors affecting the power output of a PV system. Although summer offers longer daylight hours and higher irradiance, rising ambient

Get a quote

Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV

The operating temperature plays a key role in the photovoltaic conversion process. Both the electrical efficiency and the power output of a photovoltaic (PV) module depend

Get a quote

How Temperature Impacts Solar Cell Efficiency

Photovoltaic cells exhibit optimal efficiency within a specific temperature range, typically between 15°C (59°F) and 35°C (95°F). This range

Get a quote

How Temperature Impacts Solar Cell Efficiency

Photovoltaic cells exhibit optimal efficiency within a specific temperature range, typically between 15°C (59°F) and 35°C (95°F). This range varies slightly depending on the

Get a quote

How Does Temperature Affect Battery Performance?

A study by Scientific Reports found that an increase in temperature from 77 degrees Fahrenheit to 113 degrees Fahrenheit led to a 20% increase in maximum storage capacity. However there is

Get a quote

PV module specifications and performance parameters

The nameplate ratings on photovoltaic (PV) panels and modules summarize safety, performance, and durability specifications. Safety standards include UL1730, UL/IEC61730,

Get a quote

Study on the Influence of Light Intensity on the

For the measurement of light intensity on the surface of the photovoltaic cell module, a Tm-207 solar power meter was used to measure

Get a quote

Temperature and PV Performance Optimization | AE 868:

In regard to the temperature, when all parameters are constant, the higher the temperature, the lower the voltage. This is considered a power loss. On the other hand, if the temperature

Get a quote

What impact does temperature have on the longevity of solar

Accelerated Degradation: High temperatures can cause solar batteries to degrade faster, reducing their lifespan. This is particularly true for lithium-ion batteries commonly used

Get a quote

PV array temperature correction table (NEC 2017)

There are calculators like this one made by @upnorthandpersonal which help you calculate PV array voltage and power for low temperatures

Get a quote

The Effect of Heat and Temperature on Photovoltaic

PV modules and cells are meant to convert the light from the sun into electricity. This implies hours and hours of exposure to the sun’s heat

Get a quote

Solar Panel Degradation: What Is It and Why Should

To understand the lifespan limitations of PV modules, you should comprehend the concept of solar panel degradation. This is the main

Get a quote

Investigation of Degradation of Solar Photovoltaics: A

The degradation of solar photovoltaic (PV) modules is caused by a number of factors that have an impact on their effectiveness, performance,

Get a quote

How Does Temperature Affect Battery Performance?

A study by Scientific Reports found that an increase in temperature from 77 degrees Fahrenheit to 113 degrees Fahrenheit led to a 20% increase in

Get a quote

Temperature Effects on PV Modules

In high temperatures, modules with insufficient voltage may be unable to fully charge a lead acid battery. As additional unused power in PV modules is reduced in high temperature, so is the

Get a quote

The Effects of Temperature on Photovoltaic and Different

When the temperature of photovoltaic modules (PVM) increases during operation, it leads to a decline in the output, a significant concern for engineers and users.

Get a quote

6 FAQs about [Is the battery temperature of photovoltaic modules high ]

How does temperature affect a PV module?

This impact is linear and increases with temperature. In high temperatures, modules with insufficient voltage may be unable to fully charge a lead acid battery. As additional unused power in PV modules is reduced in high temperature, so is the advantage of MPPT charge controllers.

What temperature should a photovoltaic cell be heated?

Photovoltaic cells exhibit optimal efficiency within a specific temperature range, typically between 15°C (59°F) and 35°C (95°F). This range varies slightly depending on the type of PV cell technology and the specific materials used in its construction.

How does temperature affect a photovoltaic cell?

Temperature plays a crucial role in determining the efficiency and performance of photovoltaic (PV) cells. The efficiency of a PV cell refers to its ability to convert sunlight into electrical energy, and this efficiency is directly influenced by the operating temperature of the cell.

What role does operating temperature play in photovoltaic conversion?

The operating temperature plays a key role in the photovoltaic conversion process. Both the electrical efficiency and the power output of a photovoltaic (PV) module depend linearly on the operating temperature.

What happens if a PV module is arranged into a module?

The arrangement of PV cells into a module changes the flow of heat into and out of the module. A changed flow of heat means that the temperature at which the module operates increases. This increase in the temperature causes a lowered output voltage for the PV module. This implies a reduced output power.

How is the operating temperature of a PV module determined?

The operating temperature of a PV module is determined using the equilibrium between the heat that the PV module produces, the heat that the PV module loses to the environment, and the ambient operating temperature.

Guess what you want to know

-

What are battery photovoltaic modules

What are battery photovoltaic modules

-

Lithium battery cells and photovoltaic modules

Lithium battery cells and photovoltaic modules

-

Lithium battery station cabinet high temperature

Lithium battery station cabinet high temperature

-

Moldova photovoltaic energy storage lithium battery brand

Moldova photovoltaic energy storage lithium battery brand

-

High-efficiency double-glass solar photovoltaic modules

High-efficiency double-glass solar photovoltaic modules

-

China-Europe communication base station lead-acid battery photovoltaic power generation external cooling

China-Europe communication base station lead-acid battery photovoltaic power generation external cooling

-

Outdoor photovoltaic energy storage lithium battery

Outdoor photovoltaic energy storage lithium battery

-

Mozambique photovoltaic energy storage cabinet lithium battery

Mozambique photovoltaic energy storage cabinet lithium battery

-

What are the battery cabinet temperature control systems

What are the battery cabinet temperature control systems

-

Is the voltage between the battery and the BMS high or low

Is the voltage between the battery and the BMS high or low

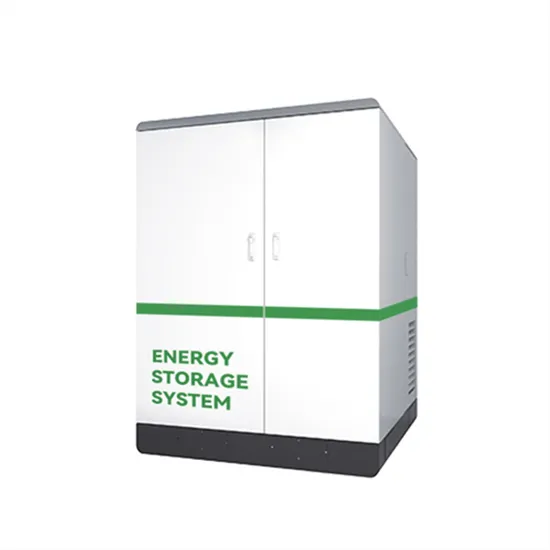

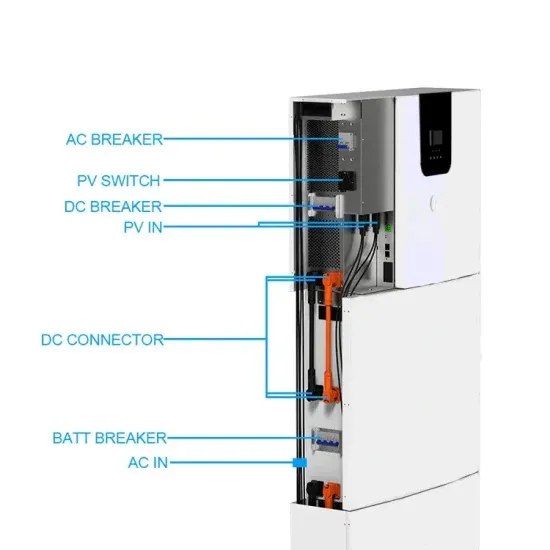

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.