Liquid cooling system optimization for a cell‐to‐pack battery

Cell-to-pack (CTP) structure has been proposed for electric vehicles (EVs). However, massive heat will be generated under fast charging. To address the temperature control and thermal

Get a quote

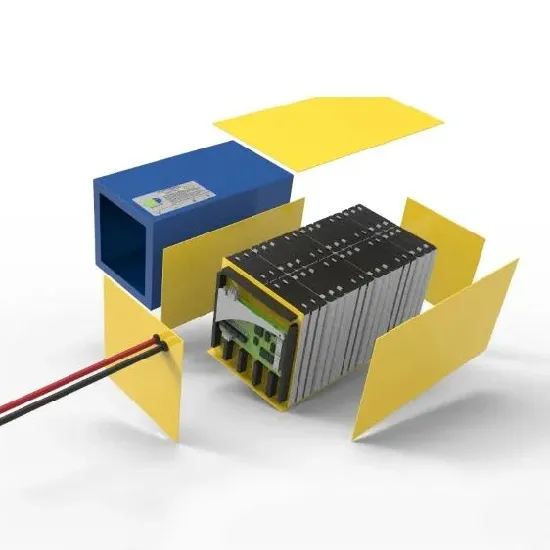

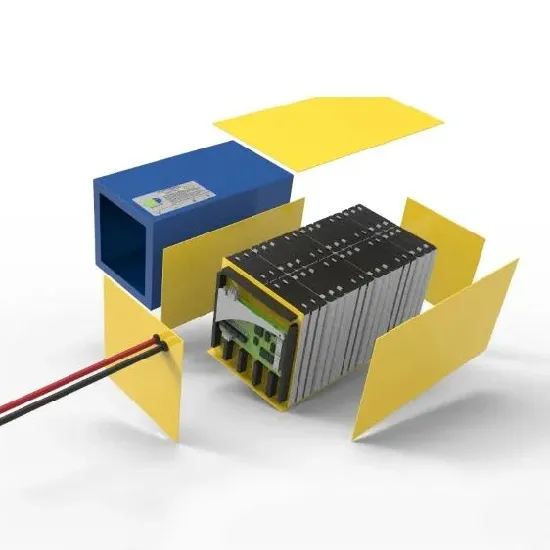

Liquid-cooling Module

The battery module is equipped with a cutting-edge TRM achieved through the strategic placement of double-faced mica fireproofing insulation foam between battery cells.

Get a quote

A Complete Analysis of Power Battery Thermal Management: Why Has Liquid

Liquid cooling performs best in thermal runaway protection, sealing, and NVH (noise and vibration). Although the initial cost of liquid cooling is higher than that of air cooling, it can

Get a quote

(PDF) Liquid cooling system optimization for a cell-to-pack battery

To address the temperature control and thermal uniformity issues of CTP module under fast charging, experiments and computational fluid dynamics (CFD) analysis are carried

Get a quote

A novel pulse liquid immersion cooling strategy for Lithium-ion

Ensuring the lithium-ion batteries'' safety and performance poses a major challenge for electric vehicles. To address this challenge, a liquid immersion battery thermal

Get a quote

Study of Cooling Performance of Liquid-Cooled EV Battery

Finally, liquid cooling, which involves the utilization of an insulated liquid coolant, is used to cool batteries in pure EVs, which have high power demands. Depending on the

Get a quote

Working Principle of Liquid Cooling Battery Packs

These channels are strategically placed in close proximity to the battery cells. The coolant is pumped through these channels by a dedicated coolant pump. This

Get a quote

Design and Thermal Performance Analysis of a Liquid Cooling

Meanwhile, the circular-fin cooling configuration exhibited noticeable heat accumulation in the lower-middle section of the battery pack, likely due to localized coolant

Get a quote

Research on liquid-cooling structure for lithium-ion battery with

Abdulateef et al. (Abdulateef et al., 2017) crafted a triangular-shaped bionic cooling configuration aimed at cylindrical lithium-ion battery packs, enhancing their thermal dissipation

Get a quote

An up-to-date review on the design improvement and

On the current electric vehicle (EV) market, a liquid-cooling battery thermal management system (BTMS) is an effective and efficient thermal management solution for

Get a quote

Working Principle of Liquid Cooling Battery Packs

These channels are strategically placed in close proximity to the battery cells. The coolant is pumped through these channels by a dedicated coolant pump. This pump is typically

Get a quote

Liquid Cooled BESS 1.6MW x 3MWh

Each battery pack utilizes an independent liquid cooling topology which allows for better heat dissipation and cell temperature consistency. Liquid cooling allows for higher pack power and

Get a quote

A novel pulse liquid immersion cooling strategy for Lithium-ion battery

Ensuring the lithium-ion batteries'' safety and performance poses a major challenge for electric vehicles. To address this challenge, a liquid immersion battery thermal

Get a quote

Principles of liquid cooling pipeline design

This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition, selection and design

Get a quote

A Review of Advanced Cooling Strategies for Battery

The present review summarizes numerous research studies that explore advanced cooling strategies for battery thermal management in EVs.

Get a quote

Analyzing the Liquid Cooling of a Li-Ion Battery Pack

Using COMSOL Multiphysics® and add-on Battery Design Module and Heat Transfer Module, engineers can model a liquid-cooled Li-ion battery pack to study and

Get a quote

A review of thermal management for Li-ion batteries: Prospects

Li-ion batteries is mature and well settled in EV industry and can be promising in introducing fast charging technologies via required cooling system integration to the battery pack.

Get a quote

2.5MW/5MWh Liquid-cooling Energy Storage System Technical

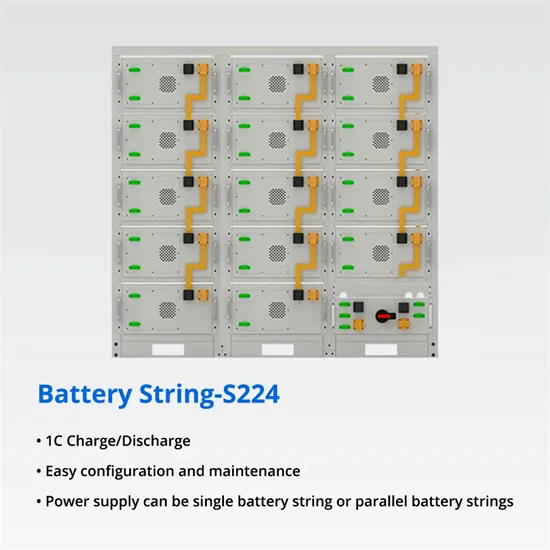

The configuration scheme based on project requirements is as follows: Battery Cluster: All cells use 314Ah lithium iron phosphate batteries. Each battery module is grouped in a 1P52S

Get a quote

Thermal management scheme and optimization of

References [50,51] combined air-cooled and liquid-cooled battery thermal management systems can better control the temperature difference to the battery pack. The

Get a quote

Liquid-Cooled Battery Packs: Boosting EV Performance | Bonnen

In order to design a liquid cooling battery pack system that meets development requirements, a systematic design method is required. It includes below six steps.

Get a quote

Analyzing the Liquid Cooling of a Li-Ion Battery Pack

To address the temperature control and thermal uniformity issues of CTP module under fast charging, experiments and computational fluid

Get a quote

Analysis and design of module-level liquid cooling system for

An effective battery thermal management system (BTMS) can extend the service life of batteries and avoid thermal runaway. In this study, a liquid-cooling management system

Get a quote

A Complete Analysis of Power Battery Thermal Management:

Liquid cooling performs best in thermal runaway protection, sealing, and NVH (noise and vibration). Although the initial cost of liquid cooling is higher than that of air cooling, it can

Get a quote

Liquid Immersion Cooling for Battery Packs

Ricardo has publicly demonstrated its immersion-cooled battery pack using Shell''s dielectric fluid. The design emphasizes modularity and serviceability, while offering consistent

Get a quote

Liquid Cooling Tube | Serpentine Tube – XD Thermal

Battery packs are composed of numerous battery cells arranged in a specific configuration. Therefore, when considering thermal management for batteries,

Get a quote

Guess what you want to know

-

Battery cabinet liquid cooling technology principle

Battery cabinet liquid cooling technology principle

-

Battery cabinet liquid cooling energy storage

Battery cabinet liquid cooling energy storage

-

Battery cabinet liquid cooling production

Battery cabinet liquid cooling production

-

Lithium battery liquid cooling energy storage

Lithium battery liquid cooling energy storage

-

Energy storage cabinet battery liquid cooling installation site

Energy storage cabinet battery liquid cooling installation site

-

Portugal new energy pack battery

Portugal new energy pack battery

-

Reduce the structure of lithium battery pack

Reduce the structure of lithium battery pack

-

Specific parameters of lithium iron phosphate battery pack

Specific parameters of lithium iron phosphate battery pack

-

Pack lithium battery is the most professional

Pack lithium battery is the most professional

-

Pack lithium battery future

Pack lithium battery future

Industrial & Commercial Energy Storage Market Growth

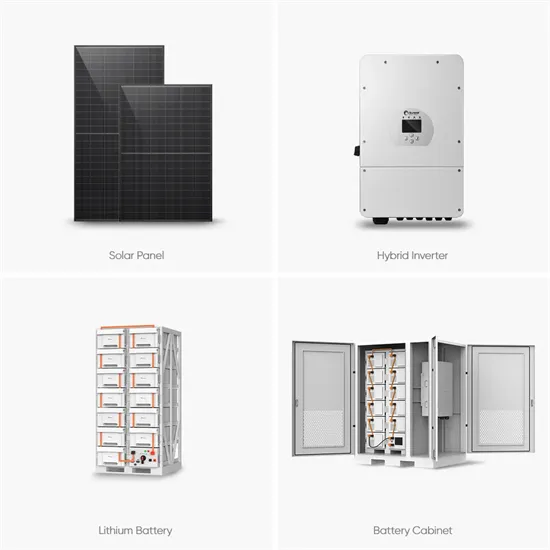

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.