Understanding Lithium Battery Pack Enclosure Design for Electric

Understanding Lithium Battery Pack Enclosure Design for Electric Vehicles and Boats At Bonnen Battery, we specialise in crafting high-performance lithium-ion (Li-ion)

Get a quote

Complete Guide to Lithium Battery Pack Design and Assembly

At the same time, using a high-strength structural design can resist impact from collisions. This ensures safety during use. You can choose lightweight materials like aluminum

Get a quote

Factors Influencing the Design of Custom Lithium-Ion

Let''s delve deeper into the factors that shape the design of lithium-ion battery packs and how they influence the performance and safety of your

Get a quote

Optimization and Structural Analysis of Automotive Battery Packs

Through weight reduction and structural optimization, an innovative power battery pack design scheme is proposed, aiming to achieve a more efficient and lighter electric vehicle

Get a quote

The Handbook of Lithium-Ion Battery Pack Design

Abstract Lithium-ion (Li-ion) batteries are everywhere today. introduces the topic of Li-ion batteries and Li-ion battery design to the reader and outlines the flow of the book with the intention of

Get a quote

Top Tips to Reduce Self-Discharge in Lithium Batteries for

Higher temperatures and a high state of charge accelerate self-discharge of lithium battery packs, leading to faster capacity decay and shorter life. Elevated self-discharge

Get a quote

Design approaches for Li-ion battery packs: A review

The goal is to analyze the methods for defining the battery pack''s layout and structure using tools for modeling, simulations, life cycle analysis, optimization, and machine

Get a quote

Optimization of lithium-ion battery pack thermal performance: A

This study fills that void by thoroughly examining how battery tabs, busbars, electrical configurations (series–parallel), and discharge rates collectively influence both

Get a quote

Effect of Vibration on Lithium Battery Performance

Note: Implementing robust shock absorption technologies and protective casings can significantly reduce the adverse effects of vibration on

Get a quote

Optimize the Weight of EVs Lithium-ion Battery Packs | Bonnen

There are five effective ways to make a lightweight lithium-ion battery pack for EVs: 1. Optimize the layout of battery packs. In the limited space of the battery pack box, a certain

Get a quote

The Batteries of the Future Are Weightless and Invisible

A lithium-ion battery inside a phone or EV battery pack has four main components: the cathode, anode, electrolyte, and the separator.

Get a quote

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

Pouch cells feature flexible packaging without rigid outer casing, enabling customizable form factors. The lightweight construction provides 40% weight reduction

Get a quote

Understanding EV battery structure: What it consists of

Discover the secrets of EV battery structure! Uncover what powers electric cars, from cells to packs, and how they boost performance & range.

Get a quote

Factors Influencing the Design of Custom Lithium-Ion Battery Packs

Let''s delve deeper into the factors that shape the design of lithium-ion battery packs and how they influence the performance and safety of your applications. A lithium-ion

Get a quote

Complete Guide to Lithium Battery Pack Design and Assembly

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get a quote

Heat dissipation optimization of lithium-ion battery pack based on

The excessively high temperature of lithium-ion battery greatly affects battery working performance. To improve the heat dissipation of battery pack, many researches have

Get a quote

Bidirectional Active Equalization Control of Lithium

Aiming at the energy inconsistency of each battery during the use of lithium-ion batteries (LIBs), a bidirectional active equalization topology of

Get a quote

Lithium-ion Battery: Structure, Working Principle and Package

Ⅰ. What is a lithium-ion battery? Lithium batteries are divided into lithium batteries and lithium-ion batteries. Both mobile phones and laptops use lithium-ion batteries, commonly

Get a quote

The Ultimate Guide to 18650 Battery Packs: Design,

The 18650 battery pack is a modular energy storage system built from 18650 cylindrical lithium-ion cells, each measuring 18mm in diameter and 65mm in

Get a quote

Techniques for mitigating thermal runaway in batteries

While good thermal management, structural design, and battery management can reduce the risk, there is always the possibility of defects or

Get a quote

Lithium Ion Battery Packaging: Soft Pack Design Guide

Soft-pack lithium-ion battery packaging encloses battery cells in a flexible, laminated aluminum-plastic film instead of traditional hard casing. This

Get a quote

Equalization strategy of lithium-ion battery packs under two-level

To tackle this problem, lithium-ion battery packs are created by linking several lithium-ion batteries together in a series arrangement. This approach enables them to fulfill the

Get a quote

The Construction of a Lithium-Ion Battery Pack: An In-Depth

Balancing: To maintain optimal performance, the BMS balances the charge across all cells. This is essential because slight differences in cell characteristics can lead to uneven

Get a quote

Design of Adaptive Multimode Equalization Circuit

By analyzing the real-time state of charge (SOC) parameters of the battery pack, the equalization circuit can adaptively select the current equalization mode to

Get a quote

What is the shelf life of lithium-ion rechargeable batteries and how

Lithium-ion battery shelf life depends on storage, usage, and chemistry. Learn how to extend battery longevity with proper handling and storage tips.

Get a quote

Lithium Ion Battery Packaging: Soft Pack Design Guide

Soft-pack lithium-ion battery packaging encloses battery cells in a flexible, laminated aluminum-plastic film instead of traditional hard casing. This design reduces weight and size,

Get a quote

Design of Adaptive Multimode Equalization Circuit Based on

By analyzing the real-time state of charge (SOC) parameters of the battery pack, the equalization circuit can adaptively select the current equalization mode to reduce the inconsistency of the

Get a quote

6 FAQs about [Reduce the structure of lithium battery pack]

What is a power battery pack design scheme?

Through weight reduction and structural optimization, an innovative power battery pack design scheme is proposed, aiming to achieve a more efficient and lighter electric vehicle power system.

How do you protect a lithium ion battery?

Tabs must pass through the pouch wall, which creates potential leak points. Ensuring a tight, durable seal around tabs is one of the design’s hardest parts. Even tiny amounts of water or oxygen can degrade lithium-ion batteries. The laminated pouch film must be an excellent barrier to protect the cell.

Can a high-strength steel reduce the weight of a battery pack?

Xiong et al. studied a novel procedure that significantly reduced the weight of the battery pack by improving its crashworthiness. Advanced high-strength steels (ADDSs) have been investigated in the designing of battery packs for the weight reduction and on the same time ensuring enhanced crashworthiness.

Does a lower battery pack design have significant redundancy?

The analysis results indicate that the strength of the battery pack meets the allowable requirements, suggesting that the lower housing design has significant redundancy, providing guidance for subsequent optimization.

Does electrical configuration affect thermal properties of lithium-ion batteries?

Lastly, existing research overlooks the impact of electrical configuration on thermal properties, particularly in series-connected lithium-ion battery setups where voltage fluctuations and state of charge variations pose safety and reliability concerns.

How to design a Li-ion battery unit?

The first design approach described in the literature for designing a Li-ion battery unit is the Heuristic approach. The battery size and capacity are defined considering an acceptable range and average energy consumption without simulations and optimization analysis.

Guess what you want to know

-

Syria lithium battery prices reduce energy storage

Syria lithium battery prices reduce energy storage

-

Papua New Guinea lithium battery pack price

Papua New Guinea lithium battery pack price

-

How many cells are in a 36v lithium battery pack

How many cells are in a 36v lithium battery pack

-

Is Niue s lithium battery pack safe

Is Niue s lithium battery pack safe

-

Technology New Energy Lithium Battery Pack

Technology New Energy Lithium Battery Pack

-

36v lithium battery pack power

36v lithium battery pack power

-

Lithium battery pack production plant in Indonesia

Lithium battery pack production plant in Indonesia

-

Lithium battery pack capacity normal voltage high

Lithium battery pack capacity normal voltage high

-

Lithium battery pack outer box container base station

Lithium battery pack outer box container base station

-

Cote d Ivoire pack lithium battery factory

Cote d Ivoire pack lithium battery factory

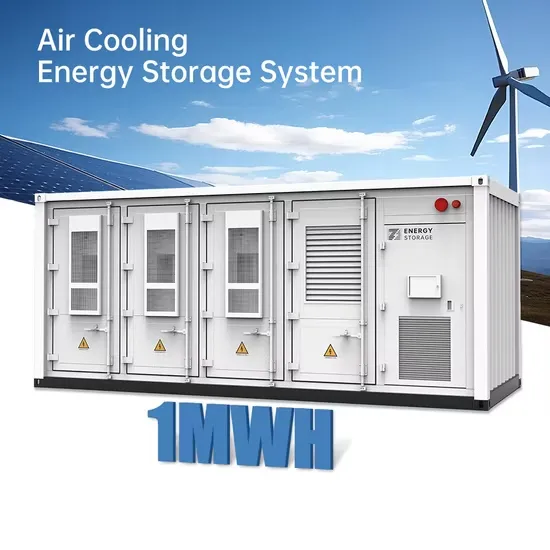

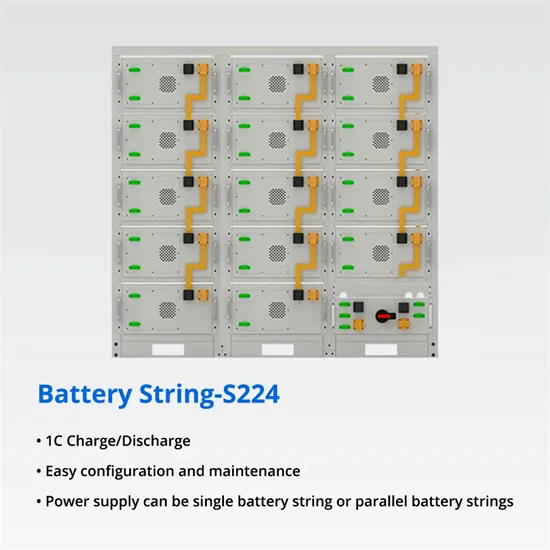

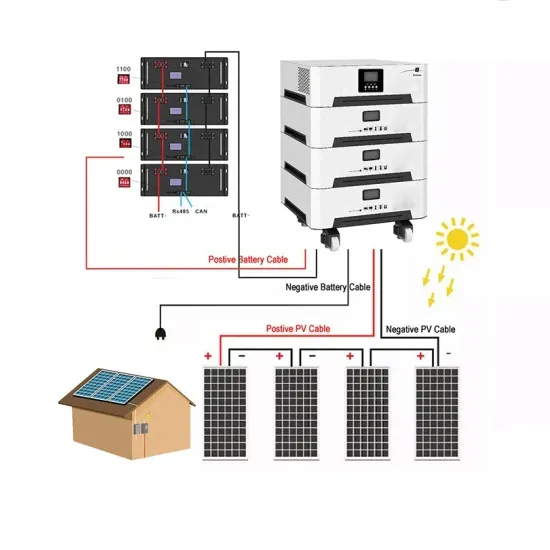

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.