The Growing Demand for Silica Sand in Solar Panel Manufacturing

In this exploration, we unravel the increasing demand for silica sand in the production of solar panels, understanding its role in shaping the renewable energy landscape.

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

Solar Manufacturing Cost Analysis NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and

Get a quote

Full article: Methods of extracting silica and silicon

ABSTRACT The beneficiation of agricultural waste is a topical issue in the field of sustainable and renewable energy production. This review

Get a quote

Ethical Solar Panels | Investigating the sustainable brands.

The parallels to silicon production for solar panels are clear: high silica content, hazardous dust, and severe health risks. This growing awareness has led to calls for banning engineered

Get a quote

Homerun Resources | About Silica

HPQ silica sand plays a role in renewable energy technologies like solar panels due to its high purity and thermal resistance. It enhances the efficiency and

Get a quote

What is silica solar panel material? | NenPower

Silica solar panels, known formally as silicon-based photovoltaic systems, represent a significant breakthrough in harnessing solar energy. The

Get a quote

What is the Manufacturing Process of Solar Panels?

The manufacturing process of solar panels primarily involves silicon cell production, panel assembly, and quality assurance. Starting from

Get a quote

why silica sand used in Solar Panels

Silica sand is a key component in the production of solar panels, playing a crucial role in harnessing solar energy. This specialized type of sand is rich in silicon dioxide, serving

Get a quote

Why Silica Sand is Critical for Solar Panel Manufacturing

Silica sand is mined and washed to remove impurities. It is then processed into high-purity quartz. Quartz is melted and formed into solar glass sheets. These sheets become the transparent

Get a quote

Indonesia''s quartz sand export ban seen to push

Indonesia''s quartz sand export ban seen to push domestic solar panel manufacturing The government hopes a ban will prompt a rush into the

Get a quote

Purification of Silica Sand for Solar Panels & Glass

ZLD technology is particularly advantageous when producing Low-Iron Glass Silica Sand for Solar Panels, where environmental considerations are

Get a quote

New Method of Solar Grade Silicon Production

The objective of this project is creation of ecologically clean method for production of solar grade polysilicon feedstock (SGPF) as raw material for PVCs, and also raw material for producing

Get a quote

Silica Sand in the production of Solar Panels in UAE, Spain & Egypt

In this informative article, we will delve into the fascinating world of silica sand in the production of solar panels, exploring its crucial functions, the solar industry''s growth, economic significance,

Get a quote

Purification of Silica Sand for Solar Panels & Glass

ZLD technology is particularly advantageous when producing Low-Iron Glass Silica Sand for Solar Panels, where environmental considerations are paramount. There is not one specification for

Get a quote

Analogical environmental cost assessment of silicon flows used in solar

This study provides valuable insights into the environmental impacts of these two major solar panel manufacturing countries by examining the silicon life cycle, from production

Get a quote

Reshoring silicon photovoltaics manufacturing contributes to

Reshoring silicon photovoltaic manufacturing back to the U.S. improves domestic competitiveness, advances decarbonization goals, and contributes to mitigating climate change.

Get a quote

HPQ SILICA SOLUTIONS PROCESSING TO

Silica sand is a key component in the production of solar panels. Specifically, HPQ silica sand is used to make the solar glass and is the raw material for silicon wafers that are the primary

Get a quote

Building Better Solar Panels with High-Purity Silica Sand

This article explores the indispensable role of silica sand in solar panel manufacturing and how Purnomo Silica delivers high-purity, sustainable

Get a quote

Mining Raw Materials for Solar Panels: Problems and

But manufacturing the solar panels necessary for such a huge increase in solar power production will require a surge in the mining of raw

Get a quote

China is churning out solar panels—and upsetting sand markets

China is churning out solar panels—and upsetting sand markets The hunt for grains with a silica concentration of more than 99.9%

Get a quote

From sand to solar panels: Unveiling the journey of

High-purity silica is key for producing polysilicon, also known as polycrystalline silicon. This high-purity form of silicon is used as the raw

Get a quote

What is silica solar panel material? | NenPower

Silica solar panels, known formally as silicon-based photovoltaic systems, represent a significant breakthrough in harnessing solar energy. The key focus is on silicon''s role as a

Get a quote

From sand to solar panels: Unveiling the journey of solar panel

High-purity silica is key for producing polysilicon, also known as polycrystalline silicon. This high-purity form of silicon is used as the raw material for solar cells. To obtain it,...

Get a quote

Allup targets solar panel industry with high-grade silica

Silica is a key component in the manufacture of solar panels. Image: Minerals Council of Australia Silica sand is used in the production of

Get a quote

The Minerals in Solar Panels and Solar Batteries

Multiple critical and rare earth minerals are used in manufacturing solar panels and solar batteries. Learn about the mining, refining, and

Get a quote

Highly transparent, superhydrophobic, and durable silica/resin self

Therefore, combined with nanomaterials, the use of the sol-gel process is a simple and suitable technological approach for the large-scale production of superhydrophobic

Get a quote

Homerun Resources | About Silica

HPQ silica sand plays a role in renewable energy technologies like solar panels due to its high purity and thermal resistance. It enhances the efficiency and lifespan of these energy

Get a quote

Building Better Solar Panels with High-Purity Silica Sand

This article explores the indispensable role of silica sand in solar panel manufacturing and how Purnomo Silica delivers high-purity, sustainable solutions that drive the industry''s growth.

Get a quote

Guess what you want to know

-

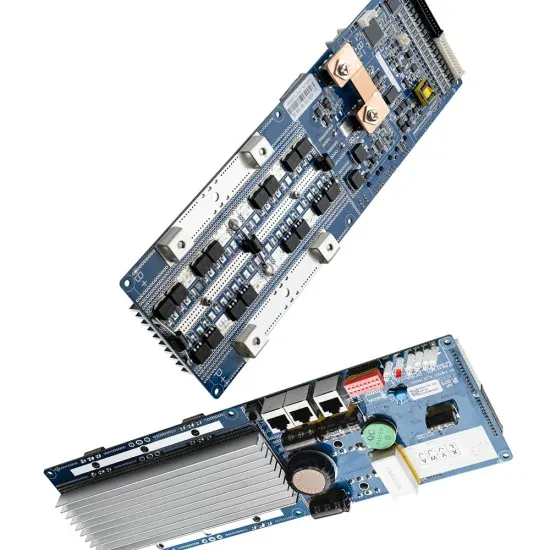

Smart production of solar panels

Smart production of solar panels

-

Production of home solar photovoltaic panels

Production of home solar photovoltaic panels

-

Photovoltaic solar panels in Uruguay

Photovoltaic solar panels in Uruguay

-

Three solar panels of different wattages

Three solar panels of different wattages

-

Huawei barium strontium solar panels

Huawei barium strontium solar panels

-

Can solar photovoltaic panels be used without batteries

Can solar photovoltaic panels be used without batteries

-

Which brand of photovoltaic solar panels is good

Which brand of photovoltaic solar panels is good

-

The market share of photovoltaic transparent solar panels

The market share of photovoltaic transparent solar panels

-

Advantages and Disadvantages of Huawei Photovoltaic Borosilicate Solar Panels

Advantages and Disadvantages of Huawei Photovoltaic Borosilicate Solar Panels

-

Flexible bifacial solar panels

Flexible bifacial solar panels

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.