Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get a quote

Solar Panel Manufacturing: A Comprehensive Guide for Beginners

Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to capture energy from the sun and convert it into usable electricity. This involves

Get a quote

The Performance and Production of a Solar Panel

There are tools to track the production and performance of your solar panels efficiently and in real time. This allows a calculation of the yield of

Get a quote

Solar Manufacturing Cost Analysis | Solar Market

Solar Manufacturing Cost Analysis NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and

Get a quote

The Performance and Production of a Solar Panel GUIDE

There are tools to track the production and performance of your solar panels efficiently and in real time. This allows a calculation of the yield of a solar panel and gives you,

Get a quote

Solar Panel Manufacturing: A Step-by-Step Overview

In this guide, we will cover the basics of solar panel manufacturing — including the various components of a solar module, the photovoltaics manufacturing process, the

Get a quote

How Much Energy Does A Solar Panel Produce? –

These days, the latest and best solar panels for residential properties produce between 250 and 400 Watts of electricity. While solar panel systems start at 1

Get a quote

Solar Panel Manufacturing: A Step-by-Step Overview

In this guide, we will cover the basics of solar panel manufacturing — including the various components of a solar module, the photovoltaics

Get a quote

PVWatts Calculator

Estimates the energy production of grid-connected photovoltaic (PV) energy systems throughout the world. It allows homeowners, small building owners, installers and manufacturers to easily

Get a quote

Solar explained

Solar photovoltaic systems Solar photovoltaic (PV) devices, or solar cells, convert sunlight directly into electricity. Small PV cells can power calculators, watches, and other small

Get a quote

Executive summary – Solar PV Global Supply Chains

Today, electricity-intensive solar PV manufacturing is mostly powered by fossil fuels, but solar panels only need to operate for 4-8 months to offset their

Get a quote

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get a quote

Solar Panel Manufacturing : Process, Production Stages

Solar panels are a vital component of renewable energy systems, converting sunlight into electricity. Understanding the manufacturing processes of solar panels is

Get a quote

How to Manufacture Solar Panel – A Complete Guide

In this guide, we will take you through the step-by-step process of manufacturing solar panels, discussing the materials used, production methods, and cost factors involved.

Get a quote

59 Solar PV Power Calculations With Examples Provided

Learn the 59 essential solar calculations and examples for PV design, from system sizing to performance analysis. Empower your solar planning or

Get a quote

How much electricity do solar panels produce?

How much electricity do solar panels produce? Solar panels generate electricity during the day. They generate more electricity when the sun shines directly on

Get a quote

Solar Panels, Solar Energy and Panel Manufacturers

Our track record speaks for itself As one of the leading solar photovoltaic manufacturers in the world, Trinasolar delivers a smart, industry leading

Get a quote

Life Cycle Greenhouse Gas Emissions from Solar Photovoltaics

Life Cycle Greenhouse Gas Emissions from Solar Photovoltaics Over the last thirty years, hundreds of life cycle assessments (LCAs) have been conducted and published for a variety of

Get a quote

Solar Panel Manufacturing: A Comprehensive Guide

Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to capture energy from the sun and convert it into usable

Get a quote

How are solar panels manufactured? | Solar

We know solar panels as the futuristic-looking black or blue rectangles that soak up sunlight and bring down our energy bills. We might even get the technology behind how they

Get a quote

How Much Energy Does A Solar Panel Produce? – Forbes Home

These days, the latest and best solar panels for residential properties produce between 250 and 400 Watts of electricity. While solar panel systems start at 1 KW and produce between 750

Get a quote

U.S. Solar Photovoltaic Manufacturing

Solar PV devices use semiconducting materials, mainly crystalline silicon (CS), to convert sunlight to electricity. The solar CS PV value chain comprises four primary stages of manufacturing,

Get a quote

How to Manufacture Solar Panel – A Complete Guide

In this guide, we will take you through the step-by-step process of manufacturing solar panels, discussing the materials used, production

Get a quote

Photovoltaics and electricity

Photovoltaic cells convert sunlight into electricity A photovoltaic (PV) cell, commonly called a solar cell, is a nonmechanical device that converts sunlight directly into

Get a quote

Guess what you want to know

-

Cuban home solar photovoltaic panels

Cuban home solar photovoltaic panels

-

Is it good to install solar photovoltaic panels at home

Is it good to install solar photovoltaic panels at home

-

Latest home solar photovoltaic panels

Latest home solar photovoltaic panels

-

Solar photovoltaic panels for waterproofing

Solar photovoltaic panels for waterproofing

-

Malta Solar Photovoltaic Panels BESS

Malta Solar Photovoltaic Panels BESS

-

Photovoltaic panels insulation Can solar panels generate electricity

Photovoltaic panels insulation Can solar panels generate electricity

-

Photovoltaic and thin-film solar panels which is better

Photovoltaic and thin-film solar panels which is better

-

Are solar photovoltaic panels considered monocrystalline silicon

Are solar photovoltaic panels considered monocrystalline silicon

-

Brand new solar photovoltaic panels for sale in Azerbaijan

Brand new solar photovoltaic panels for sale in Azerbaijan

-

Libya produces photovoltaic modules and solar panels

Libya produces photovoltaic modules and solar panels

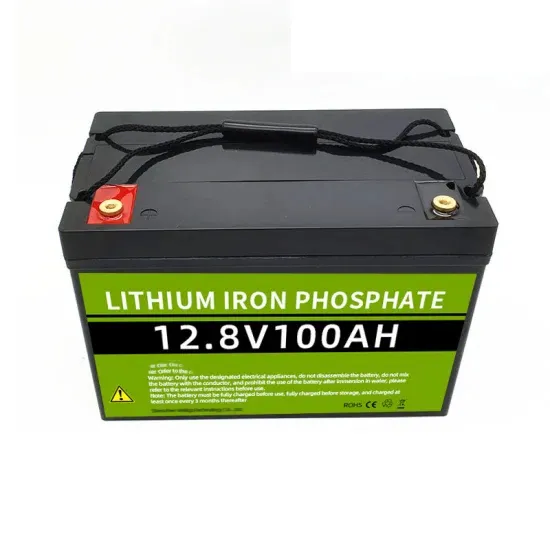

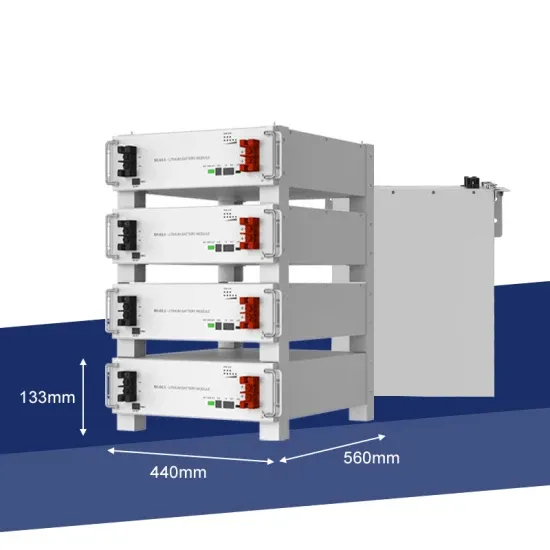

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.