Monocrystalline vs Polycrystalline Panels: Which Is

When choosing the best solar panel for home, most homeowners and businesses find themselves debating between Monocrystalline vs

Get a quote

The Different Types of Solar Panels Explained: What Kind of Solar

Discover the Pros and Cons of the Most Used Types of Solar Panels-Monocrystalline, Polycrystalline & Thin-film (amorphous) Solar Panels & Much More.Act Now!

Get a quote

Monocrystalline Silicon

Monocrystalline silicon is a type of silicon that is used in the production of solar panels. It is called "monocrystalline" because the silicon used in these panels is made up of a

Get a quote

Types of photovoltaic cells

Several of these solar cells are required to construct a solar panel and many panels make up a photovoltaic array. There are three types of PV cell technologies that dominate the world

Get a quote

A Complete Guide to PERC Solar Panels (vs. Other

Recapping the structure and workings of traditional solar panels Before diving into PERC solar panel technology and its benefits, it is important

Get a quote

What Is a Monocrystalline Solar Panel? Definition,

Monocrystalline solar panels deliver exceptional performance of up to 25% thanks to their construction from a single silicon crystal. The use of

Get a quote

Monocrystalline Solar Panels

Efficiency is another benefit. Monocrystalline panels convert the highest amount of solar energy into electricity. So if you want to produce the most electricity from one specific area or you

Get a quote

What Materials are Used to Make Solar Panels?

The research on silicon material is constantly growing, which is mainly focused on improving its efficiency and sustainability. Monocrystalline and multi-crystalline silicon are the

Get a quote

Monocrystalline vs. Polycrystalline: The Hidden Structure Behind

3 days ago· Summary Learn the critical difference between monocrystalline and polycrystalline structures. This guide covers their impact on solar panel efficiency and new research on

Get a quote

What Is Monocrystalline Silicon and Why Is It Dominant in Solar Panels?

Monocrystalline silicon is a high-purity form of silicon used extensively in the production of solar panels. Characterized by its uniform structure and high efficiency, it has

Get a quote

Perovskite Solar Cells: An In-Depth Guide

The most common types of solar panels are manufactured with crystalline silicon (c-Si) or thin-film solar cell technologies, but these are not

Get a quote

Types of Solar Panels: Monocrystalline vs

Introduction: Solar panels are a popular choice for renewable energy generation. It is important to understand the different types of solar

Get a quote

What is Monocrystalline Solar Panel: A Consolidated Guide

Yes, there are different types of solar panels based on their efficiency. Today we will find in detail what is monocrystalline solar panel, its features and advantages. What is

Get a quote

Environmental impact assessment of monocrystalline silicon solar

Abstract Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate

Get a quote

Solar panel types and differences: monocrystalline

Of course, the choice of photovoltaic modules should be more recognized brand, not only to effectively reduce the sunlight reflectivity, while allowing the battery

Get a quote

What Is Monocrystalline Silicon and Why Is It Dominant in Solar

Monocrystalline silicon is a high-purity form of silicon used extensively in the production of solar panels. Characterized by its uniform structure and high efficiency, it has

Get a quote

What is Monocrystalline Solar Panel: A Consolidated Guide

Monocrystalline silicon is widely recognized as the gold standard in the solar photovoltaic panel industry. This type of silicon is produced from a

Get a quote

Monocrystalline vs. Polycrystalline solar panels

The main difference between the two technologies is the type of silicon solar cell they use: monocrystalline solar panels have solar cells made from a single silicon crystal. In

Get a quote

The difference between monocrystalline silicon and polycrystalline

Overall, monocrystalline silicon is suitable for high demand electronic and semiconductor fields, while polycrystalline silicon is more suitable for solar cells and certain

Get a quote

What Is a Monocrystalline Solar Panel? Definition, Performance

Monocrystalline solar panels deliver exceptional performance of up to 25% thanks to their construction from a single silicon crystal. The use of pure silicon creates a uniform

Get a quote

Solar panel types and differences: monocrystalline silicon

Of course, the choice of photovoltaic modules should be more recognized brand, not only to effectively reduce the sunlight reflectivity, while allowing the battery photoelectric conversion

Get a quote

A Guide to Monocrystalline Solar Panels

Monocrystalline solar panels have the further advantage of tending to be less affected by high temperatures when compared with polycrystalline solar panels. While this

Get a quote

Monocrystalline vs Polycrystalline Solar Panels

Solar cells are composed of semiconductor materials, such as silicon, used in the microelectronics industry. For solar cells, a thin semiconductor wafer is specially treated to

Get a quote

Silicon Cell

Silicon cells are not restricted only to cells based on the crystal structure. There are also silicon nanowire cells (SiNWs), which are under intense investigation for photovoltaic applications, as

Get a quote

Monocrystalline vs Polycrystalline Solar Panels:

Compare the differences in their manufacturing processes to understand how monocrystalline solar cells are made from a single, high

Get a quote

Monocrystalline vs. Polycrystalline Solar Panels

A solar panel is a composition of solar photovoltaic (PV) cells that absorb light from the sun and convert it into electricity. Typically, solar cells are made of silicon.

Get a quote

What kind of silicon is used in solar photovoltaic panels?

Monocrystalline silicon is widely recognized as the gold standard in the solar photovoltaic panel industry. This type of silicon is produced from a single, continuous crystal

Get a quote

6 FAQs about [Are solar photovoltaic panels considered monocrystalline silicon ]

What is a monocrystalline solar panel?

Monocrystalline solar panels have black-colored solar cells made of a single silicon crystal and usually have a higher efficiency rating. However, these panels often come at a higher price. Polycrystalline solar panels have blue-colored cells made of multiple silicon crystals melted together.

What is a polycrystalline solar panel?

Polycrystalline solar panels are also made from silicon. However, instead of using a single silicon crystal, manufacturers melt many silicon fragments together to form wafers for the panel. Polycrystalline solar cells are also called "multi-crystalline" or many-crystal silicon.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

Are thin-film solar panels better than polycrystalline solar panels?

Polycrystalline silicon solar panels, for example, are less expensive to produce than monocrystalline silicon panels, but they are also less efficient. Thin-film solar panels, on the other hand, are lightweight and flexible, but they have a lower efficiency and a shorter lifespan compared to monocrystalline silicon panels.

How are monocrystalline solar panels made?

Each monocrystalline solar panel is made of 32 to 96 pure crystal wafers assembled in rows and columns. The number of cells in each panel determines the total power output of the cell. How are Polycrystalline Solar Panels Made? Polycrystalline also known as multi-crystalline or many-crystal solar panels are also made from pure silicon.

What is the efficiency of a monocrystalline photovoltaic (PV) panel?

With an efficiency rate of up to 25%, monocrystalline panels reach higher efficiency levels than both polycrystalline (13-16%) and thin-film (7-18%) panels. Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

Guess what you want to know

-

Photovoltaic panels monocrystalline silicon double glass

Photovoltaic panels monocrystalline silicon double glass

-

Silicon for solar photovoltaic panels

Silicon for solar photovoltaic panels

-

Solar photovoltaic panels are considered illegal construction

Solar photovoltaic panels are considered illegal construction

-

Solar monocrystalline silicon photovoltaic panel lifespan

Solar monocrystalline silicon photovoltaic panel lifespan

-

The power generation efficiency of monocrystalline silicon photovoltaic panels

The power generation efficiency of monocrystalline silicon photovoltaic panels

-

Photovoltaic panels are made of monocrystalline silicon

Photovoltaic panels are made of monocrystalline silicon

-

Monocrystalline silicon solar panels 300 watts

Monocrystalline silicon solar panels 300 watts

-

Differences between monocrystalline silicon photovoltaic panels and polycrystalline silicon photovoltaic panels

Differences between monocrystalline silicon photovoltaic panels and polycrystalline silicon photovoltaic panels

-

Solar polycrystalline silicon photovoltaic panels

Solar polycrystalline silicon photovoltaic panels

-

Photovoltaic solar panels monocrystalline bifacial

Photovoltaic solar panels monocrystalline bifacial

Industrial & Commercial Energy Storage Market Growth

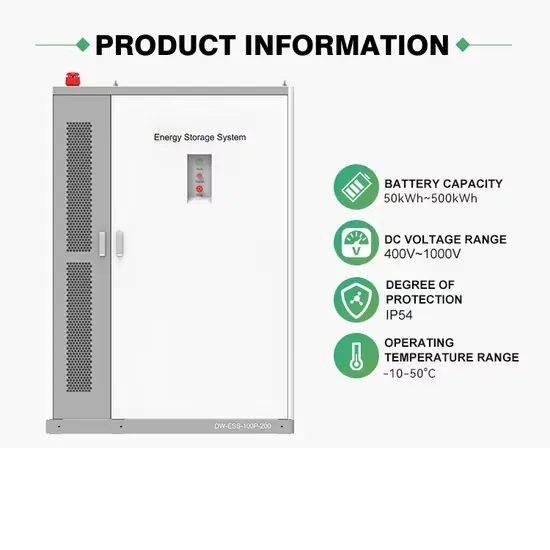

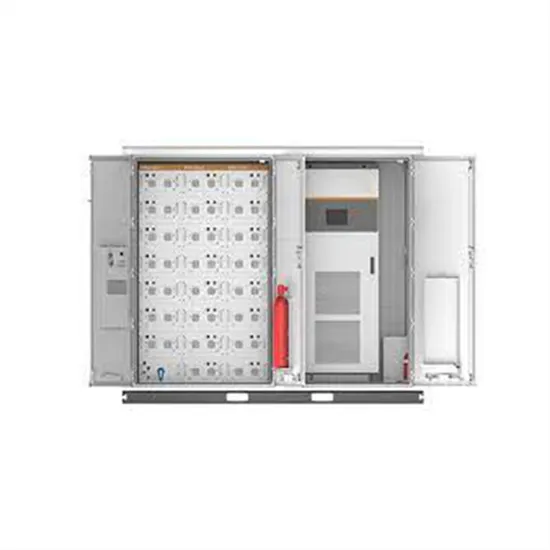

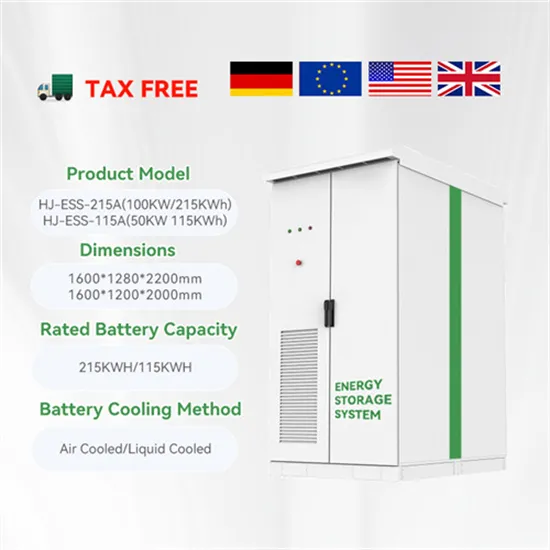

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

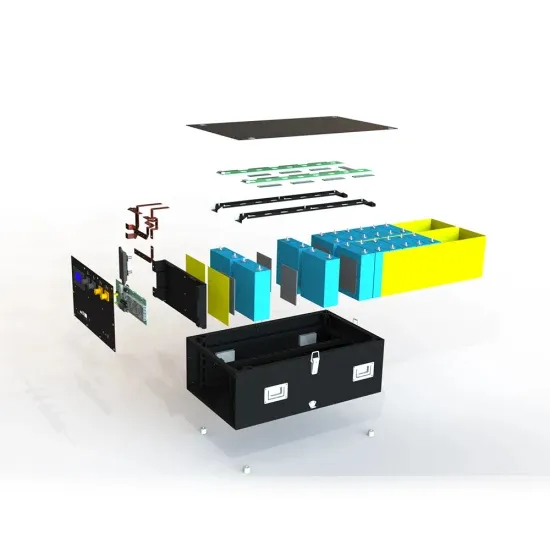

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.