What Are Amorphous Solar Panels, and Should You

Amorphous solar panels use the same silicon-based photovoltaic technology that exists in the common solar panel, but without the solar cell.

Get a quote

What kind of silicon is used in solar photovoltaic panels?

Monocrystalline and polycrystalline silicon represent two primary categories of silicon used in solar photovoltaic panels. The essential difference lies in their manufacturing

Get a quote

Silicon Solar Cells

Silicon is the primary material used in solar cells due to its cost-effectiveness, high energy efficiency, photoconductivity, corrosion resistance, and natural abundance.

Get a quote

Why Silicon Remains the Top Choice for Solar Panels

Silicon solar panels have their own challenges, but their unmatched combination of efficiency, affordability, durability, and proven technology secures their position at the

Get a quote

Flexible silicon solar cells that can roll up

Highly efficient silicon solar cells that are as flexible as a sheet of paper could offer a lightweight power source for applications such as uncrewed aerial

Get a quote

What is the silicon used in solar power generation?

Silicon used in solar power generation manifests in various forms, primarily classified into monocrystalline, polycrystalline, and amorphous

Get a quote

Oxford commercializes its 20% more powerful solar

Oxford PV has revealed a "world-first" commercial sale of its tandem solar panels that produce 20% more energy than standard silicon panels.

Get a quote

Silicon Solar Cells

Key Takeaways Silicon is the primary material used in solar cells due to its cost-effectiveness, high energy efficiency, photoconductivity, corrosion resistance,

Get a quote

Solar Photovoltaic Cell Basics

Silicon is, by far, the most common semiconductor material used in solar cells, representing approximately 95% of the modules sold today. It is also the

Get a quote

How Crystalline Silicon Becomes a PV Cell

To make solar cells, high purity silicon is needed. The silicon is refined through multiple steps to reach 99.9999% purity. This hyper-purified silicon is known as solar grade

Get a quote

What Are Solar Panels Made of? Full Materials Guide

Find out what solar panels are made of, including silicon cells, glass, aluminum, and wiring, and how these materials affect efficiency and durability.

Get a quote

Why Silicon is the Most Widely Used Material in Solar Panels

Discover why silicon is used in solar panels as the key material for harvesting clean energy efficiently. Explore its vital role in solar technology.

Get a quote

Why Silicon is the Most Widely Used Material in Solar

Discover why silicon is used in solar panels as the key material for harvesting clean energy efficiently. Explore its vital role in solar technology.

Get a quote

What Is a Silicon Wafer for Solar Cells?

Silicon wafers are a fundamental component in virtually all modern electronics and over 90% of solar cells & panels worldwide. But why? And how do they

Get a quote

How Crystalline Silicon Becomes a PV Cell

To make solar cells, high purity silicon is needed. The silicon is refined through multiple steps to reach 99.9999% purity. This hyper-purified

Get a quote

What Are Solar Panels Made Of and How Are They Made?

Answering that question means understanding how solar energy works, how solar panels are manufactured, and what the parts of a solar panel are. Most panels on the market

Get a quote

Crystalline Silicon Photovoltaics Research

Monocrystalline silicon represented 96% of global solar shipments in 2022, making it the most common absorber material in today''s solar modules. The remaining 4% consists of other

Get a quote

What''s the Difference Between Silicon Solar Panels

Crystalline-silicon solar panels are efficient, reliable, and dominate the solar-panel market. However, new third-gen solar technology could do

Get a quote

Understanding Crystalline Silicon PV Technology

Understanding photovoltaic technology, and in particular, crystalline silicon PV technology is crucial for those seeking to adopt renewable energy

Get a quote

Why Silicon Remains the Top Choice for Solar Panels

Silicon solar panels have their own challenges, but their unmatched combination of efficiency, affordability, durability, and proven

Get a quote

Breaking Down Solar Panels and What They Are Really Made Of

1 day ago· Q3: Are the materials in what solar panels are made of sustainable? Yes, materials like silicon and aluminum in what solar panels are made of are abundant, recyclable.

Get a quote

Crystalline Silicon Photovoltaics

These have high efficiency, making crystalline silicon photovoltaics an interesting technology where space is at a premium. Crystalline silicon solar cells There

Get a quote

New 100% American silicon solar panel supply chain

After REC Silicon closed shop and Qcells lost its domestic polysilicon supply, the country has been lacking a roadmap for a 100%

Get a quote

What Are Solar Panels Made Of?

The bottom line Solar panels are made from a combination of silicon, aluminium, glass, and various other materials. The abundance and durability of silicon and glass

Get a quote

What is the silicon used in solar power generation? | NenPower

Silicon used in solar power generation manifests in various forms, primarily classified into monocrystalline, polycrystalline, and amorphous silicon. Each type possesses

Get a quote

What kind of silicon is used in solar photovoltaic panels?

Monocrystalline and polycrystalline silicon represent two primary categories of silicon used in solar photovoltaic panels. The essential difference

Get a quote

Solar Panel Manufacturing: From Selenium to Silicon

The journey of solar panel manufacturing, a cornerstone of renewable energy manufacturing, has been marked by significant technological advancements, evolving from the

Get a quote

Solar Photovoltaic Cell Basics

Silicon is, by far, the most common semiconductor material used in solar cells, representing approximately 95% of the modules sold today. It is also the second most abundant material on

Get a quote

Guess what you want to know

-

Monocrystalline silicon solar panels 300 watts

Monocrystalline silicon solar panels 300 watts

-

Are solar photovoltaic panels considered monocrystalline silicon

Are solar photovoltaic panels considered monocrystalline silicon

-

Silicon for solar panels

Silicon for solar panels

-

Solar panels are polycrystalline silicon

Solar panels are polycrystalline silicon

-

Solar photovoltaic panels for power companies

Solar photovoltaic panels for power companies

-

146 volt solar photovoltaic panels

146 volt solar photovoltaic panels

-

Fiji s double-sided solar panels

Fiji s double-sided solar panels

-

Reasons for building solar panels for communication base stations

Reasons for building solar panels for communication base stations

-

Road installation with solar photovoltaic panels

Road installation with solar photovoltaic panels

-

Algeria sells solar photovoltaic panels

Algeria sells solar photovoltaic panels

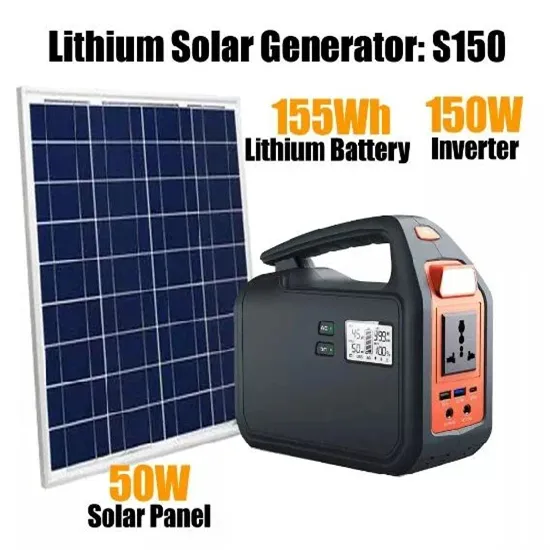

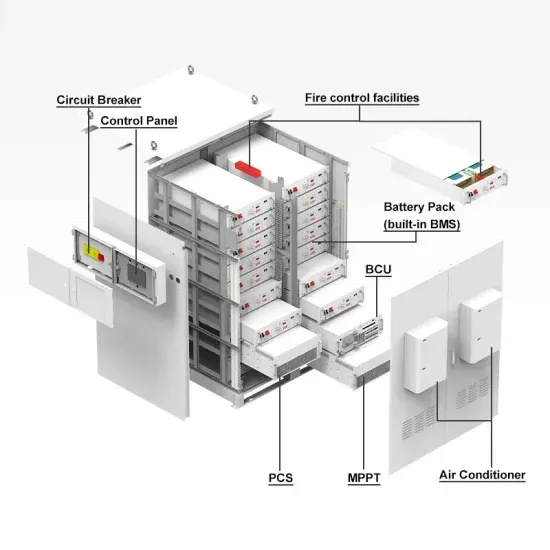

Industrial & Commercial Energy Storage Market Growth

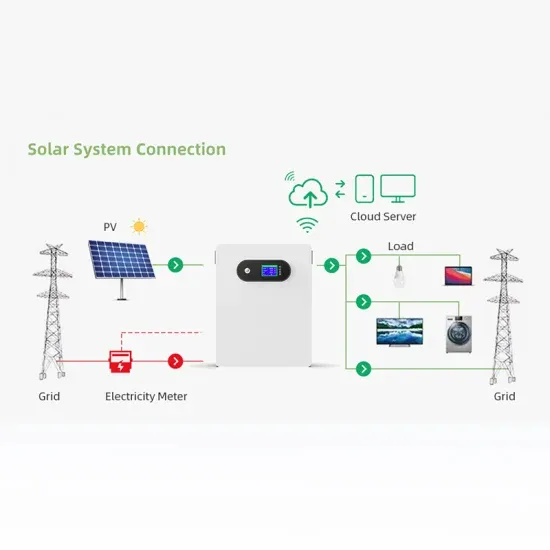

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

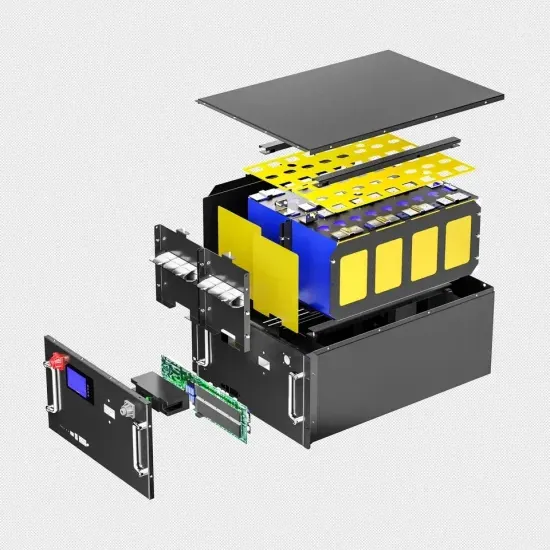

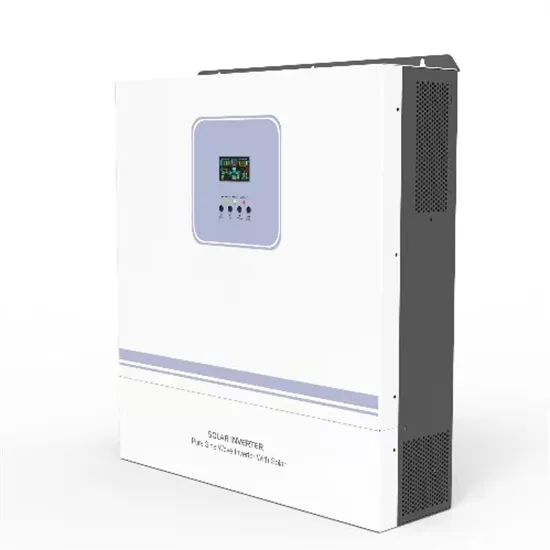

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.