BC58 Battery Cabinet Installation, Operation, & Maintenance

Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Get a quote

Battery Module Cabinet Guide: Definition, Uses & Design

3 days ago· A Battery Module Cabinet stores and manages battery modules for UPS, telecom, and energy storage, ensuring safety, scalability, and efficiency.

Get a quote

Communication network cabinet battery interface

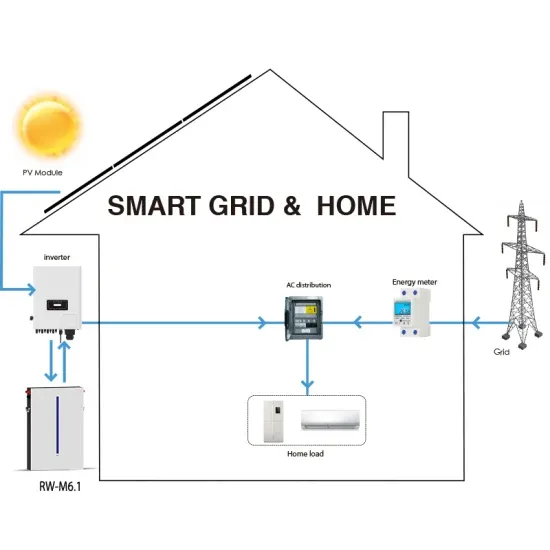

The communication interface plays a crucial role in attaining system-level integration in a larger environment. It enables the BMS to communicate vital battery condition data to other

Get a quote

164201687_1085_Rev_4_Web

In the middle battery cabinets, locate the battery-cabinet-to-battery-cabinet Shunt Trip and Aux battery interface cable with connector P3. Route this connector into the next cabinet and mate

Get a quote

CATL Cabient Energy Storage System Solutions

Catl C&I Cabinet Energy Storage System prodcut introduction of cell, module, high voltage box, outdoor battery cabinet, Outdoor Combiner cabinet.

Get a quote

Energy Storage Battery Pack Enclosure size optimization and

Learn about the industry-leading ESS Battery Enclosure specifications and efficient layout strategies of CATL, BYD, etc., to improve system space utilization and reliability.

Get a quote

UPS Battery Cabinets

BC 2 300X/500 Battery Conditioning (pgs. 35-36) in ZincFive''s BC 2 Series UPS Battery Cabinet Service Manual for the recomended UPS LVCO and expected power levels in the customer

Get a quote

1500V 2MW Outdoor Battery Cabinet Energy Storage

1500V 2MW Outdoor Battery Cabinet Energy Storage Systems Battery ESS Battery for C&I ESS Details Save on shipping costs, transport with batteries:

Get a quote

Powerware 9395 Integrated Battery Cabinet (Model IBC-L)

Use this procedure to install the battery cabinet. The battery cabinet shown in Figure 4-2 is located adjacent to the UPS cabinet, but may be located in a separate location.

Get a quote

Eaton Power Xpert 9395 Installation And Operation

View and Download Eaton Power Xpert 9395 installation and operation manual online. UPS and Samsung Gen 3 Battery Cabinet System. Power Xpert 9395

Get a quote

Energy Storage Battery Interfaces: A Picture Guide for

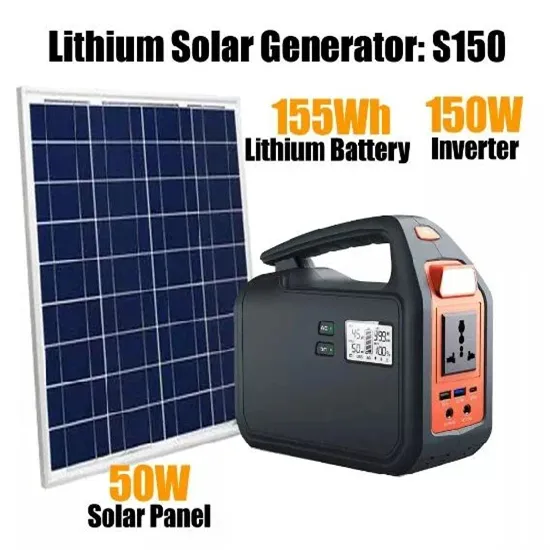

Let''s face it – most folks searching for energy storage battery interface pictures fall into two camps: DIY homeowners trying to install solar setups, and engineers optimizing commercial

Get a quote

EATON 93PM INSTALLATION MANUAL Pdf Download

Page 59: Figure 26. 93Pm Integrated Battery Cabinet Battery String Detail Schematic Onelines and Schematics Figure 26. 93PM Integrated Battery Cabinet Battery String Detail Schematic

Get a quote

Complete Guide for Battery Enclosure

From battery box design, and fabrication, to quality inspection – our team handles every process for you. Our team will help you choose the right material, recommend the best

Get a quote

Eaton Samsung Gen 3 Battery Cabinet Installation and

Interface wiring for features and options should be connected at the customer interface terminals and connector blocks located on the interface tray located inside the Eaton Samsung Gen 3

Get a quote

CATL Cabient Energy Storage System Solutions ESS

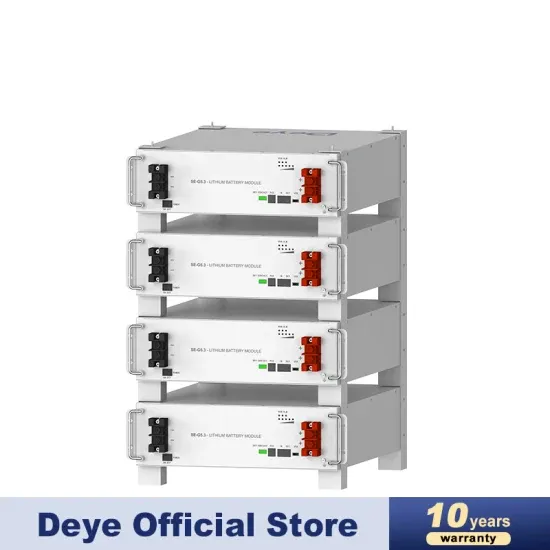

C&I Products – 51.2V 200AH LiFePO4 Battery Module Security Design: Connection detection Module short circuit protection Maintenance Convenience Design: Pre-maintenance interface,

Get a quote

CATL Cabient Energy Storage System Solutions ESS

C&I Products – 51.2V 200AH LiFePO4 Battery Module Security Design: Connection detection Module short circuit protection Maintenance

Get a quote

Eaton Samsung Gen 3 Battery Cabinet Installation and

This manual describes how to install the Eaton Samsung Gen 3 battery cabinet and is divided into chapters. Read and understand the procedures described to ensure trouble-free installation

Get a quote

Liebert® EXS External Battery Cabinet Installer/User Guide

This manual contains important instructions that should be followed during installation of your VertivTM Liebert® EXS Battery Cabinet and accessories. Read this manual thoroughly, paying

Get a quote

Vertiv Liebert® APM2 Modular EBC User Manual

Save these instructions This manual contains important instructions that should be followed during installation of VertivTM Liebert® APM2 Modular External Battery Cabinet (EBC) and

Get a quote

Complete Guide for Battery Enclosure

This manual contains information on Atlantic Battery Systems battery cabinets. The information in this manual is intended for Qualified Installers, Equipment Engineers, and Field Support

Get a quote

Battery Cabinet

This manual contains information on Atlantic Battery Systems battery cabinets. The information in this manual is intended for Qualified Installers, Equipment Engineers, and Field Support

Get a quote

6 FAQs about [Battery cabinet installation interface design]

How do I install a battery cabinet?

tween each battery cabinet and the UPS or battery disconnect using conduit. Batt ry cabinets may be installed adjacent to the UPS or in a separate location.If the battery cabinet is installed adjacent to the UPS, the recommended installati n location for the battery cabinet is on the right side of the UPS cabi

What is a battery cabinet (IBC) system?

Battery Cabinet (IBC) systems are housed in single free-standing cabinets. Model IBC-L with a ingle battery voltage range is available to meet application runtime nee s. Up to four cabinets may be installed to further ext nd battery runtimes. The cabinets match the UPS cabinet in style

How do I install the 9395 model IBC-L Battery Cabinet?

serve a preferred startup date.1.1 Configuration and installation featuresThe 9395 Model IBC-L battery cabinet is designed to e installed in a standalone configuration using up tp two battery cabinets. Power wiring is installed externally b tween each battery cabinet and the UPS or battery disconnect using conduit. Batt

How is a battery system installed?

installed on a level floor suitable for computer or electronic equip nt.Each cabinet in the battery system is placed in its correct location.A cabinet ground g/mounting kit is installed between any cabinets hat are bolted together.A ground wire is installed between all cab ets.All conduits and cables are properly routed to the bat

What is a battery cabinet?

y current.The battery cabinet is installed in a standalone configuration. The term standalonerefers to battery cabinets that may be installed adjacent to the UPS or in a separate location, are wired with external customer-supplied conduit and wiring, and may use the battery cabinet breaker as the battery isolation device or a sin

How to connect ups CABI & Battery Cabinet?

ing between the UPS and battery cabinet is to be provided by the customer.When installing external interface wiring (for example, battery breaker shunt trip) to the battery cabinet interface terminals, conduit must be installed between the battery cabinets and the UPS cabi

Guess what you want to know

-

Battery cabinet installation interface cost price

Battery cabinet installation interface cost price

-

Syria Outdoor Communication Battery Cabinet Design

Syria Outdoor Communication Battery Cabinet Design

-

Substation battery cabinet installation site

Substation battery cabinet installation site

-

Energy storage cabinet installation battery cabinet site

Energy storage cabinet installation battery cabinet site

-

Battery cabinet cooling system design principle

Battery cabinet cooling system design principle

-

New Energy Battery Cabinet Communication Base Station Design

New Energy Battery Cabinet Communication Base Station Design

-

Energy storage cabinet battery installation equipment base station

Energy storage cabinet battery installation equipment base station

-

Battery cabinet design safety

Battery cabinet design safety

-

Installation site of integrated battery cabinet

Installation site of integrated battery cabinet

-

Seychelles Outdoor Communication Battery Cabinet Installation Company Ranking

Seychelles Outdoor Communication Battery Cabinet Installation Company Ranking

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.